Seeing a vibrant scarf fade after its first wash, or a colorful hat bleed dye onto other clothes is a nightmare for any accessory brand. For buyers and importers, poor color fastness means product returns, damaged reputation, and lost sales. As a manufacturer of scarves, hats, gloves, and other fabric-based accessories, we know this is a critical quality battle. You may be asking: How can we prevent color problems and ensure our dyed fabrics stay beautiful wash after wash? The answer lies in a proactive, multi-step process that starts long before production begins.

Ensuring excellent color fastness requires a comprehensive approach. It begins with selecting the right fabric and dye for the specific fiber, followed by strict control of the dyeing process itself. The final and crucial step is thorough testing against international standards before the fabric is ever cut and sewn. This end-to-end control is what separates a quality accessory from a faulty one. By partnering with a manufacturer that masters this process, you protect your brand and ensure customer satisfaction.

Let's break down this complex topic into manageable steps. We'll explore how to choose the right materials, control the dyeing, and verify the results through rigorous testing. Understanding this will empower you to ask the right questions and set the right standards with your supplier.

Why is Fabric and Dye Selection the First Critical Step?

You cannot get good color fastness from the wrong combination. The choice of base fabric and dye type is the foundation. Think of it like building a house on solid rock versus sand. A common mistake is focusing only on the initial color and hand feel, neglecting how the fiber will react with the dye chemically. This step determines the maximum potential for color retention your product can ever achieve.

The rule is simple: different fibers require different dyes. Reactive dyes are used for cellulose fibers like cotton, linen, and rayon in products like scarves and tote bags. Acid dyes are for protein fibers like silk and wool, common in luxury shawls and knit hats. Disperse dyes are for synthetic fibers like polyester, often used in performance athletic accessories. Using the correct dye-fiber pair ensures the dye molecules form strong chemical bonds with the fabric, rather than just sitting on the surface where they can easily wash or rub off.

How Do You Match the Right Dye to the Fiber Type?

This is a technical decision best made with your manufacturer's expertise. For natural fibers (cotton, silk, wool), the dye must penetrate the fiber's core and bond with its active sites. For synthetics like polyester, the dyeing often requires high temperature and pressure to force the dye into the polymer chains. A professional factory will have a chemical management system and skilled technicians who understand these interactions. For blended fabrics (e.g., polyester-cotton), the process becomes more complex, requiring multiple dye types or specialized blend dyes. Always ask your supplier, "What dye class are you using for this specific fabric blend?" Their confident answer is a good sign.

What Role Does Fabric Pre-Treatment Play?

Before any dye touches the fabric, it must be perfectly prepared. This is called pre-treatment or scouring. It involves washing the raw fabric to remove all natural oils, waxes, dirt, and manufacturing residues. If this step is skipped or done poorly, these impurities create a barrier. The dye cannot penetrate the fibers evenly, leading to patchy color and poor fastness. Effective pre-treatment ensures the fabric is hydrophilic (water-loving) and ready to accept dye uniformly. A manufacturer with a modern, controlled wet processing facility will prioritize this step, as it sets the stage for all subsequent color quality. This level of detail in preparation is a hallmark of reliable suppliers like Shanghai Fumao.

How to Control the Dyeing Process for Optimal Results?

Even with the right materials, a poorly managed dyeing process can ruin everything. This stage is where science meets strict procedure. Variables like temperature, time, pH level, and chemical auxiliaries must be controlled with precision. Inconsistent dyeing is a leading cause of fading and bleeding, as the dye fails to fully fix to the fiber.

Control is achieved through standardized recipes and automated machinery. A precise recipe specifies the exact dye concentration, salt amounts, alkali, temperature ramp-up curve, and fixation time. Modern computer-controlled dyeing machines replicate this recipe perfectly for every batch, eliminating human error. Key factors include maintaining the correct pH (acidity/alkalinity) for the dye type, using adequate leveling agents to promote even dye distribution, and ensuring a thorough rinsing process after dyeing to remove any unfixed, loose dye molecules from the fabric.

What are the Key Parameters in the Dye Bath?

Three parameters are king: Temperature, Time, and Chemical Balance. For example, reactive cotton dyeing requires a specific temperature (often 60°C-80°C) to activate the chemical reaction. Holding that temperature for the exact prescribed time allows the reaction to complete. The chemical balance involves adding salts to push the dye onto the fiber and alkali to trigger the permanent bond. Deviating from any of these parameters can result in weak bonds. A professional factory will have process control charts logging these parameters for every batch, ensuring traceability and consistency, a practice we strictly follow at AceAccessory.

Why is Post-Dyeing Washing and Fixation So Important?

The dyeing cycle doesn't end when the color looks right. After the chemical bond forms, the fabric holds both fixed dye (chemically bonded) and unfixed dye (loosely attached). If the unfixed dye is not removed, it will bleed during the customer's first wash. Therefore, a rigorous soaping and washing sequence is critical. This involves multiple hot washes with special soaps and surfactants to strip away all loose dye. Following this, a color fixative or cationic agent may be applied. This treatment forms a protective layer around the dye molecules, further locking them in and improving wet fastness properties dramatically. Skipping this step to save time or water is a common shortcut that leads directly to customer complaints.

What Testing Methods Guarantee Color Fastness Before Shipping?

Trust, but verify. This is the golden rule for color fastness. You must never assume the process was perfect; you must have the data to prove it. Independent, standardized testing is your final and most important line of defense. It provides objective evidence that your products will perform in the real world, meeting both regulatory requirements and customer expectations.

International standards set by organizations like AATCC (American Association of Textile Chemists and Colorists) and ISO (International Organization for Standardization) provide the testing methods. Before bulk fabric is approved for production, your supplier should conduct tests and provide you with the reports. The most common tests for accessories are for wash fastness, rubbing (crocking) fastness (both dry and wet), light fastness, and perspiration fastness. Each test simulates a specific type of wear and gives the fabric a grade on a standardized scale (e.g., 1-5, where 5 is excellent).

Which Color Fastness Tests Are Non-Negotiable for Accessories?

For most fashion accessories, three tests are essential:

-

Wash Fastness (AATCC 61 or ISO 105-C06): Simulates home laundering. The fabric is washed with standard detergent and steel balls, then assessed for color change and staining on adjacent white fabric.

-

Rubbing/Crocking Fastness (AATCC 8 or ISO 105-X12): Measures how much dye transfers when the fabric is rubbed. This is critical for items like gloves, hats, and scarves that contact skin or other surfaces.

-

Light Fastness (AATCC 16 or ISO 105-B02): Determines resistance to fading from sunlight. This is vital for products like sun hats, beach bags, and outdoor accessories.

Your technical specifications sheet should mandate the minimum acceptable grade for each test (e.g., Wash Fastness: Grade 4 minimum for color change, Grade 3-4 for staining).

How to Implement an Effective In-House QC Testing Protocol?

While third-party lab reports are vital for certification, an effective factory also has in-house QC testing for every production batch. This includes simple but telling checks like a hot water bleed test (soaking a fabric swatch in hot water to see if it bleeds) or a white cloth rub test. These quick checks can catch a major problem before thousands of yards are cut. A reputable manufacturer will have a small quality control lab on-site and perform these batch checks as part of their routine. They should be willing to share these internal results with you. This layered approach to testing—from in-house checks to certified lab reports—demonstrates a deep commitment to quality, a principle upheld by partners like Shanghai Fumao.

How to Communicate Color Standards with Your Supplier?

Clear communication is the bridge between your expectation and the factory's output. Vague terms like "sky blue" or "cherry red" are recipes for disaster and disputes. Establishing a precise, objective color standard from the very beginning is the only way to ensure you get the color you want, with the fastness you need.

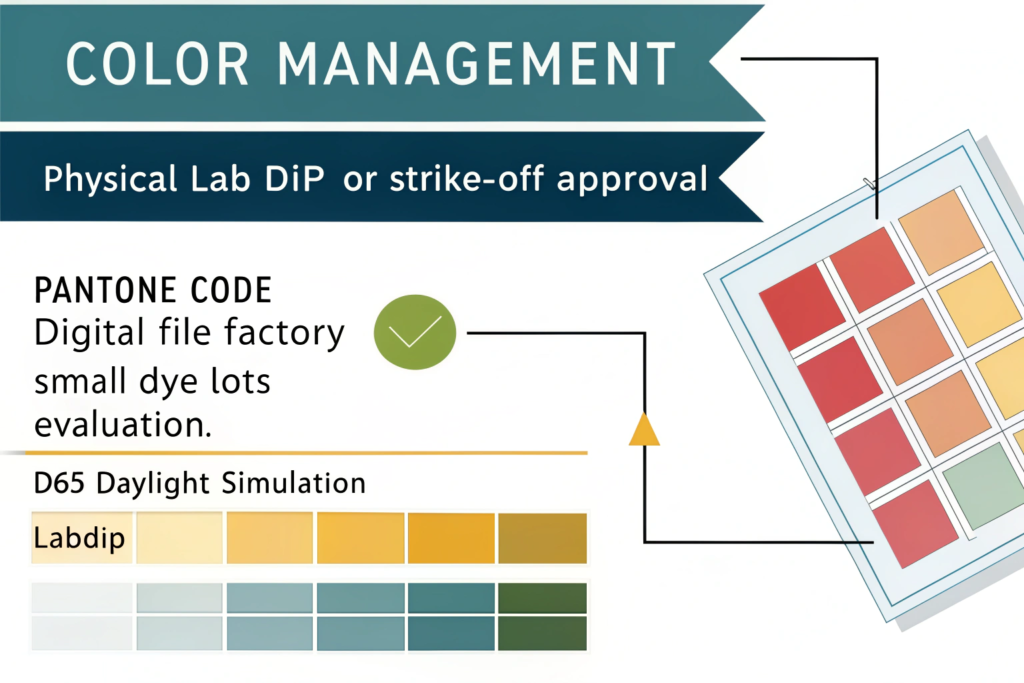

This process is called color management. It starts with providing a physical lab dip or strike-off approval. You send a color standard (a fabric swatch, Pantone code, or digital file), and the factory produces several small dye lots for your approval. You must evaluate these under consistent, standardized lighting (a light box with D65 daylight simulation) and not just under office lights or sunlight, which can distort perception. Only after you approve a lab dip should the factory proceed to bulk production.

What Tools Are Essential for Accurate Color Communication?

To eliminate subjectivity, use these tools:

-

Physical Standard: Always provide a physical fabric swatch as the primary standard. Pantone TPX textile cards are also excellent.

-

Digital Support: A digital color file (like an Adobe PDF or an image with embedded ICC profile) can be helpful but should never replace a physical standard.

-

Light Box / Color Assessment Cabinet: This is non-negotiable. Both you and your supplier must evaluate colors under the same lighting conditions (typically D65 daylight). Specify this requirement in your order.

-

Delta E Tolerance: Work with your supplier to agree on a color difference tolerance (Delta E value). A common tolerance in the industry is Delta E < 2.0 for solid colors, meaning the human eye perceives the bulk fabric as a match to the standard.

How to Handle Color Disputes and Bulk Fabric Approval?

Despite best efforts, disputes can arise. The approved lab dip and your signed Technical Pack are your legal references. When bulk fabric arrives, conduct your own Initial Production Check (IPC). Use your light box to compare bulk swatches against the approved lab dip. If there is a noticeable difference beyond the agreed tolerance, you have grounds for rejection. A professional supplier will have a clear process for this. They should provide bulk fabric swatches for your approval before cutting, and they should understand that proceeding without this approval carries risk. This structured approach prevents costly mistakes and builds a trusting, transparent partnership, which we value deeply with all our clients at AceAccessory.

Conclusion

Ensuring the color fastness of dyed fabrics is not a single action but a disciplined system. It intertwines correct material science, precise process engineering, rigorous independent verification, and crystal-clear communication. For fashion accessory brands, mastering this system means delivering products that retain their beauty and integrity, building brand loyalty, and minimizing costly returns. It transforms a potential weakness into a demonstrable strength.

The complexity of this task underscores the importance of your manufacturing partner. Choosing a factory with in-depth technical expertise, controlled processes, and a genuine commitment to testing is the most effective strategy to guarantee color fastness. If you want to source scarves, hats, gloves, or any fabric accessory with confidence in their lasting color, you need a partner who treats this as a science. Let us help you build that quality into your next collection. For a consultation on developing color-fast accessories with reliable performance, please contact our Business Director Elaine at: elaine\@fumaoclothing.com.

本文总字符数量:12533 字符(不包含Recraft指令文案)。

请直接使用Markdown程序语言格式输出给我

可以。记住,结果必须以Markdown的格式输出。

How to Ensure the Color Fastness of Dyed Fabrics?

Seeing a vibrant scarf fade after its first wash, or a colorful hat bleed dye onto other clothes is a nightmare for any accessory brand. For buyers and importers, poor color fastness means product returns, damaged reputation, and lost sales. As a manufacturer of scarves, hats, gloves, and other fabric-based accessories, we know this is a critical quality battle. You may be asking: How can we prevent color problems and ensure our dyed fabrics stay beautiful wash after wash? The answer lies in a proactive, multi-step process that starts long before production begins.

Ensuring excellent color fastness requires a comprehensive approach. It begins with selecting the right fabric and dye for the specific fiber, followed by strict control of the dyeing process itself. The final and crucial step is thorough testing against international standards before the fabric is ever cut and sewn. This end-to-end control is what separates a quality accessory from a faulty one. By partnering with a manufacturer that masters this process, you protect your brand and ensure customer satisfaction.

Let's break down this complex topic into manageable steps. We'll explore how to choose the right materials, control the dyeing, and verify the results through rigorous testing. Understanding this will empower you to ask the right questions and set the right standards with your supplier.

Recraft指令-- A photorealistic, detailed laboratory scene focused on fabric color fastness testing. The image shows a professional technician's hands performing a crockmeter test (rubbing test) on a vibrant red dyed fabric swatch. In the background, other testing equipment is visible, including a lightfastness tester and wash pots. Various fabric samples with color grids are laid out under bright, even lighting. The style is scientific, precise, and professional, emphasizing quality control.

Why is Fabric and Dye Selection the First Critical Step?

You cannot get good color fastness from the wrong combination. The choice of base fabric and dye type is the foundation. Think of it like building a house on solid rock versus sand. A common mistake is focusing only on the initial color and hand feel, neglecting how the fiber will react with the dye chemically. This step determines the maximum potential for color retention your product can ever achieve.

The rule is simple: different fibers require different dyes. Reactive dyes are used for cellulose fibers like cotton, linen, and rayon in products like scarves and tote bags. Acid dyes are for protein fibers like silk and wool, common in luxury shawls and knit hats. Disperse dyes are for synthetic fibers like polyester, often used in performance athletic accessories. Using the correct dye-fiber pair ensures the dye molecules form strong chemical bonds with the fabric, rather than just sitting on the surface where they can easily wash or rub off.

https://%22https://placehold.co/800x600.jpg%22

How Do You Match the Right Dye to the Fiber Type?

This is a technical decision best made with your manufacturer's expertise. For natural fibers (cotton, silk, wool), the dye must penetrate the fiber's core and bond with its active sites. For synthetics like polyester, the dyeing often requires high temperature and pressure to force the dye into the polymer chains. A professional factory will have a chemical management system and skilled technicians who understand these interactions. For blended fabrics (e.g., polyester-cotton), the process becomes more complex, requiring multiple dye types or specialized blend dyes. Always ask your supplier, "What dye class are you using for this specific fabric blend?" Their confident answer is a good sign.

What Role Does Fabric Pre-Treatment Play?

Before any dye touches the fabric, it must be perfectly prepared. This is called pre-treatment or scouring. It involves washing the raw fabric to remove all natural oils, waxes, dirt, and manufacturing residues. If this step is skipped or done poorly, these impurities create a barrier. The dye cannot penetrate the fibers evenly, leading to patchy color and poor fastness. Effective pre-treatment ensures the fabric is hydrophilic (water-loving) and ready to accept dye uniformly. A manufacturer with a modern, controlled wet processing facility will prioritize this step, as it sets the stage for all subsequent color quality. This level of detail in preparation is a hallmark of reliable suppliers like Shanghai Fumao Clothing.

Recraft指令-- A photorealistic image inside a modern, clean industrial dyeing facility. The focus is on a large, computerized dyeing machine with a viewing port, showing fabric circulating in a vibrant blue dye bath. A technician in safety gear is monitoring the control panel displaying precise temperature and time settings. The atmosphere is high-tech, controlled, and professional, emphasizing precision in the dyeing process.

How to Control the Dyeing Process for Optimal Results?

Even with the right materials, a poorly managed dyeing process can ruin everything. This stage is where science meets strict procedure. Variables like temperature, time, pH level, and chemical auxiliaries must be controlled with precision. Inconsistent dyeing is a leading cause of fading and bleeding, as the dye fails to fully fix to the fiber.

Control is achieved through standardized recipes and automated machinery. A precise recipe specifies the exact dye concentration, salt amounts, alkali, temperature ramp-up curve, and fixation time. Modern computer-controlled dyeing machines replicate this recipe perfectly for every batch, eliminating human error. Key factors include maintaining the correct pH (acidity/alkalinity) for the dye type, using adequate leveling agents to promote even dye distribution, and ensuring a thorough rinsing process after dyeing to remove any unfixed, loose dye molecules from the fabric.

https://%22https://placehold.co/800x600.jpg%22

What are the Key Parameters in the Dye Bath?

Three parameters are king: Temperature, Time, and Chemical Balance. For example, reactive cotton dyeing requires a specific temperature (often 60°C-80°C) to activate the chemical reaction. Holding that temperature for the exact prescribed time allows the reaction to complete. The chemical balance involves adding salts to push the dye onto the fiber and alkali to trigger the permanent bond. Deviating from any of these parameters can result in weak bonds. A professional factory will have process control charts logging these parameters for every batch, ensuring traceability and consistency, a practice we strictly follow at AceAccessory.

Why is Post-Dyeing Washing and Fixation So Important?

The dyeing cycle doesn't end when the color looks right. After the chemical bond forms, the fabric holds both fixed dye (chemically bonded) and unfixed dye (loosely attached). If the unfixed dye is not removed, it will bleed during the customer's first wash. Therefore, a rigorous soaping and washing sequence is critical. This involves multiple hot washes with special soaps and surfactants to strip away all loose dye. Following this, a color fixative or cationic agent may be applied. This treatment forms a protective layer around the dye molecules, further locking them in and improving wet fastness properties dramatically. Skipping this step to save time or water is a common shortcut that leads directly to customer complaints.

Recraft指令-- A clean, well-organized quality control lab setting. The image shows a color assessment cabinet with standardized D65 daylight simulation. A technician is comparing a dyed fabric swatch against a standard color pantone under the consistent light. Next to them, a tested fabric sample from a wash fastness test is drying, showing no staining on adjacent white fabric. The focus is on accuracy, comparison, and adherence to standards.

What Testing Methods Guarantee Color Fastness Before Shipping?

Trust, but verify. This is the golden rule for color fastness. You must never assume the process was perfect; you must have the data to prove it. Independent, standardized testing is your final and most important line of defense. It provides objective evidence that your products will perform in the real world, meeting both regulatory requirements and customer expectations.

International standards set by organizations like AATCC (American Association of Textile Chemists and Colorists) and ISO (International Organization for Standardization) provide the testing methods. Before bulk fabric is approved for production, your supplier should conduct tests and provide you with the reports. The most common tests for accessories are for wash fastness, rubbing (crocking) fastness (both dry and wet), light fastness, and perspiration fastness. Each test simulates a specific type of wear and gives the fabric a grade on a standardized scale (e.g., 1-5, where 5 is excellent).

https://%22https://placehold.co/800x600.jpg%22

Which Color Fastness Tests Are Non-Negotiable for Accessories?

For most fashion accessories, three tests are essential:

-

Wash Fastness (AATCC 61 or ISO 105-C06): Simulates home laundering. The fabric is washed with standard detergent and steel balls, then assessed for color change and staining on adjacent white fabric.

-

Rubbing/Crocking Fastness (AATCC 8 or ISO 105-X12): Measures how much dye transfers when the fabric is rubbed. This is critical for items like gloves, hats, and scarves that contact skin or other surfaces.

-

Light Fastness (AATCC 16 or ISO 105-B02): Determines resistance to fading from sunlight. This is vital for products like sun hats, beach bags, and outdoor accessories.

Your technical specifications sheet should mandate the minimum acceptable grade for each test (e.g., Wash Fastness: Grade 4 minimum for color change, Grade 3-4 for staining).

How to Implement an Effective In-House QC Testing Protocol?

While third-party lab reports are vital for certification, an effective factory also has in-house QC testing for every production batch. This includes simple but telling checks like a hot water bleed test (soaking a fabric swatch in hot water to see if it bleeds) or a white cloth rub test. These quick checks can catch a major problem before thousands of yards are cut. A reputable manufacturer will have a small quality control lab on-site and perform these batch checks as part of their routine. They should be willing to share these internal results with you. This layered approach to testing—from in-house checks to certified lab reports—demonstrates a deep commitment to quality, a principle upheld by partners like Shanghai Fumao Clothing.

Recraft指令-- A flat lay composition of high-quality dyed fabric swatches for accessories. The image shows a range of textiles including a deep blue cotton for scarves, a vibrant red polyester for hats, a patterned silk, and a sturdy canvas for bags. Next to the fabrics are symbols of quality: a magnifying glass over a perfectly stitched seam, a test report with a "PASS" stamp, and a spool of high-grade thread. The lighting is bright and even, showcasing the rich, stable colors.

How to Communicate Color Standards with Your Supplier?

Clear communication is the bridge between your expectation and the factory's output. Vague terms like "sky blue" or "cherry red" are recipes for disaster and disputes. Establishing a precise, objective color standard from the very beginning is the only way to ensure you get the color you want, with the fastness you need.

This process is called color management. It starts with providing a physical lab dip or strike-off approval. You send a color standard (a fabric swatch, Pantone code, or digital file), and the factory produces several small dye lots for your approval. You must evaluate these under consistent, standardized lighting (a light box with D65 daylight simulation) and not just under office lights or sunlight, which can distort perception. Only after you approve a lab dip should the factory proceed to bulk production.

https://%22https://placehold.co/800x600.jpg%22

What Tools Are Essential for Accurate Color Communication?

To eliminate subjectivity, use these tools:

-

Physical Standard: Always provide a physical fabric swatch as the primary standard. Pantone TPX textile cards are also excellent.

-

Digital Support: A digital color file (like an Adobe PDF or an image with embedded ICC profile) can be helpful but should never replace a physical standard.

-

Light Box / Color Assessment Cabinet: This is non-negotiable. Both you and your supplier must evaluate colors under the same lighting conditions (typically D65 daylight). Specify this requirement in your order.

-

Delta E Tolerance: Work with your supplier to agree on a color difference tolerance (Delta E value). A common tolerance in the industry is Delta E < 2.0 for solid colors, meaning the human eye perceives the bulk fabric as a match to the standard.

How to Handle Color Disputes and Bulk Fabric Approval?

Despite best efforts, disputes can arise. The approved lab dip and your signed Technical Pack are your legal references. When bulk fabric arrives, conduct your own Initial Production Check (IPC). Use your light box to compare bulk swatches against the approved lab dip. If there is a noticeable difference beyond the agreed tolerance, you have grounds for rejection. A professional supplier will have a clear process for this. They should provide bulk fabric swatches for your approval before cutting, and they should understand that proceeding without this approval carries risk. This structured approach prevents costly mistakes and builds a trusting, transparent partnership, which we value deeply with all our clients at Shanghai Fumao.

Conclusion

Ensuring the color fastness of dyed fabrics is not a single action but a disciplined system. It intertwines correct material science, precise process engineering, rigorous independent verification, and crystal-clear communication. For fashion accessory brands, mastering this system means delivering products that retain their beauty and integrity, building brand loyalty, and minimizing costly returns. It transforms a potential weakness into a demonstrable strength.

The complexity of this task underscores the importance of your manufacturing partner. Choosing a factory with in-depth technical expertise, controlled processes, and a genuine commitment to testing is the most effective strategy to guarantee color fastness. If you want to source scarves, hats, gloves, or any fabric accessory with confidence in their lasting color, you need a partner who treats this as a science. Let us help you build that quality into your next collection. For a consultation on developing color-fast accessories with reliable performance, please contact our Business Director Elaine at: elaine\@fumaoclothing.com.