Imagine receiving 5,000 hair bands—only to find out the pink is two shades off and your retail buyer is furious. Color accuracy isn’t just about aesthetics. It’s about brand integrity, retailer relationships, and avoiding costly returns.

To ensure color accuracy in bulk hair band production, use Pantone color systems, confirm lab dips, approve samples under standardized lighting, and partner with factories that follow strict dye lot controls.

At AceAccessory, we know how a slight color shift can ruin an order. That’s why our workflow focuses on managing color at every step—from concept to final packing. Here's how to get it right.

How to Use Pantone Codes for Accurate Color Matching?

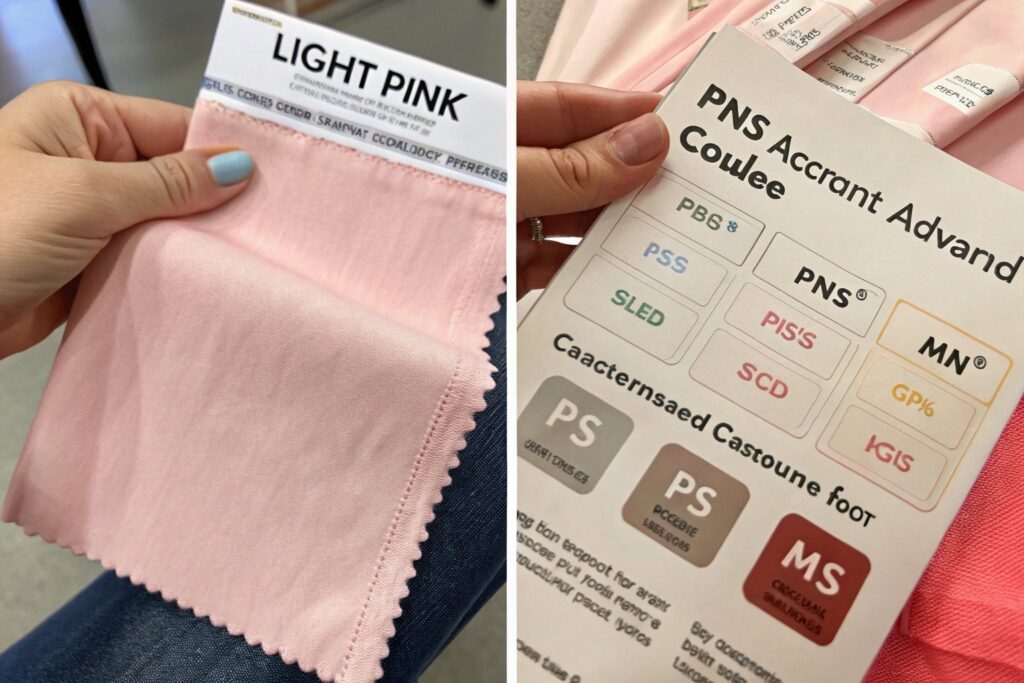

Relying on photos or "light pink" descriptions is risky. Pantone codes eliminate guesswork, offering an industry-standard reference that all global factories recognize and use.

Pantone Matching System (PMS) codes are internationally accepted numeric identifiers used to specify and reproduce exact shades across printing, dyeing, and material applications in accessory manufacturing.

How to Use Pantone Effectively in Hair Band Orders

| Step | Action |

|---|---|

| Choose Pantone Code | Use a physical Pantone book (e.g., TCX for textiles) |

| Send Code to Factory | Include in tech pack and emails |

| Request Lab Dip | Ask for dyed material swatches under Pantone lighting |

| Approve Digitally | Use calibrated screen or verify under D65 lighting |

| Confirm in Contract | Ensure bulk must match approved dip ±5% variation |

At AceAccessory, we support Pantone TCX, TPG, and Solid Coated libraries. We can match up to ±1 Delta E tolerance for premium clients and provide 3 lab dips per color for buyer approval.

For brands without Pantone books, we offer physical swatch packs and internal digital color previews calibrated to global standards.

Best Practices for Approving Color Samples Remotely

With most buyers working remotely from the U.S. or Europe, approving physical samples gets complicated. But with the right steps, you can still get confident results.

To approve color samples remotely, use physical lab dips under standard light sources, confirm using daylight or D65 lightboxes, and avoid relying solely on phone or laptop screens.

Tips for Remote Color Sample Approvals

| Practice | Why It Matters |

|---|---|

| Use Daylight/D65 Lighting | Removes bias from warm or cool indoor lighting |

| Request Large Lab Dip Swatches | Shows true fabric behavior (reflection, texture) |

| Ask for Video in Lightbox | Allows motion check for shimmer or sheen fabrics |

| Get Hardcopy Mailed | For final approval before bulk starts |

| Always Include Physical Reference | Helps align future orders or repeat runs |

AceAccessory mails physical lab dips via FedEx or UPS Express within 5–7 days. We also provide side-by-side videos comparing Pantone cards to actual material under multiple lighting conditions—natural, LED, and warm tungsten.

Our internal SOP requires buyer sign-off before mass dyeing begins. This prevents overproduction risk or mismatch with previous orders.

Common Causes of Color Variation in Mass Production

Color inconsistencies are among the top complaints in accessory manufacturing. And they often happen even when a sample looked perfect. Why?

Color variation in mass production can result from inconsistent dye batches, machine calibration issues, fabric type absorption differences, temperature fluctuations, or operator errors.

Major Causes of Color Inconsistencies

| Root Cause | Explanation |

|---|---|

| Batch Dyeing Process Variation | Each fabric dye run may vary slightly |

| Fabric Absorption Rates | Cotton vs. polyester absorb dye differently |

| Temperature/Humidity Shifts | Dye reacts differently at various conditions |

| Different Dye Factories | Sourcing from multiple partners causes mismatches |

| Manual Dyeing Setup | Operator control affects color, especially in small runs |

AceAccessory addresses this with:

- Pre-production lab dips on the exact bulk fabric

- Digital spectrophotometer testing (Delta E measurement)

- One-dye-lot-per-order commitment, unless specified

We also retain bulk fabric control swatches for all shipments, allowing clients to recheck if an issue ever arises at delivery.

Tips to Maintain Consistent Dye Lots Across Batches

Color consistency is even more critical when ordering repeat runs or replenishment stock. If the second batch doesn't match the first, you'll have unsellable mix-and-match inventory.

To maintain dye lot consistency, use the same fabric roll source, same dye house, detailed lab dip records, and request bulk lot shade bands for quality control.

Steps to Keep Color Consistent Across Batches

| Step | Impact |

|---|---|

| Save Approved Swatches | Factory must match against them each time |

| Use One Fabric Supplier | Same fiber content = same absorption behavior |

| Limit Supplier Rotation | Avoid different dyeing chemistry or SOPs |

| Request Shade Bands | Fabric roll samples for start/middle/end dye lots |

| Include Delta E Standard in PO | ±1.5 tolerance helps enforce consistency |

At AceAccessory, we:

- Store reference color books per client project

- Record Pantone + dye time + temperature settings

- Attach shade bands to all QC files and shipment records

Our color team uses Datacolor® and GretagMacbeth tools to compare batches objectively, not just visually.

Conclusion

Color accuracy makes or breaks accessory orders. With Pantone standards, careful remote approvals, proper dye control, and consistent fabric sourcing, your bulk hair band orders from China can be both beautiful and brand-perfect. AceAccessory ensures every shade is exactly how you imagined.