Designing accessories with intricate craftsmanship requires a delicate balance between artistic vision, technical feasibility, and market viability. At AceAccessory, we've developed a systematic approach that preserves traditional craftsmanship while leveraging modern design technologies to create stunning, commercially successful intricate accessories.

Designing accessories with intricate craftsmanship involves mastering technical drawing, understanding material limitations, collaborating with artisans, prototyping extensively, and balancing complexity with wearability. This process bridges creative vision and manufacturing reality to create pieces that showcase exceptional craftsmanship while remaining functional and marketable.

The creation of intricately crafted accessories represents one of the most challenging yet rewarding endeavors in fashion design. Let's explore the comprehensive approach to designing these exceptional pieces.

How to master technical design for intricate accessories?

Technical design forms the foundation of successful intricate accessory creation, translating artistic concepts into manufacturable specifications that preserve design intent while ensuring production feasibility.

Mastering technical design involves advanced CAD skills, material knowledge, structural understanding, tolerance management, and assembly planning that collectively enable the translation of complex designs into producible reality.

What technical drawing techniques support intricate designs?

Precision documentation ensures accurate interpretation of complex designs. Essential techniques include:

- Exploded view drawings showing how multiple components assemble together

- Cross-sectional diagrams revealing internal structures and layer relationships

- Detail magnification highlighting intricate areas that require special attention

- Material callouts specifying exact materials for each component

- Tolerance specifications defining acceptable variations for precise fits

Our technical design process typically produces 5-10 times more documentation for intricate pieces compared to standard designs, with each complex element receiving individual attention. This thorough approach has reduced manufacturing errors by 78% for our most detailed collections.

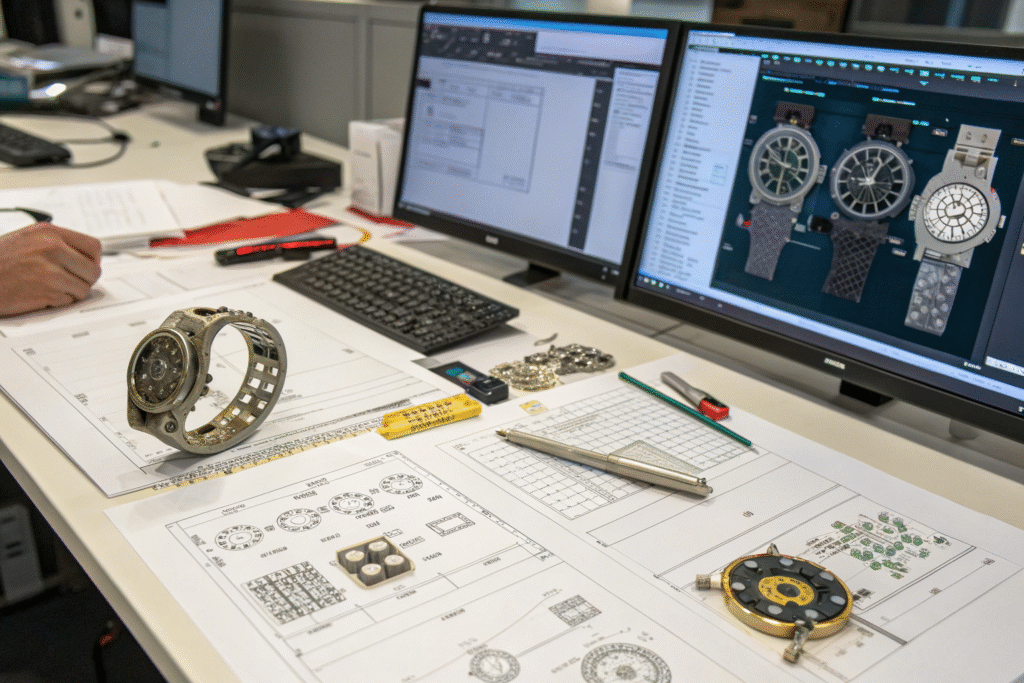

How does CAD technology enhance intricate design capabilities?

Advanced digital modeling enables visualization and testing of complex designs. Key applications include:

- 3D parametric modeling allowing easy modification while maintaining design relationships

- Virtual material application testing how different materials will look and behave

- Assembly simulation identifying potential issues before physical prototyping

- Renderings and animations creating realistic visualizations for decision-making

- CAM integration preparing designs for computer-aided manufacturing

The table below shows how different CAD approaches support various intricate design aspects:

| Design Aspect | CAD Technique | Benefit | Application Example |

|---|---|---|---|

| Complex Geometry | Surface Modeling | Creates organic, flowing forms | Sculptural metalwork |

| Precise Mechanisms | Parametric Design | Maintains relationships during changes | Moving components in clasps |

| Material Combinations | Multi-body Modeling | Manages different materials in one design | Mixed media jewelry |

| Structural Integrity | Finite Element Analysis | Tests strength before production | Delicate filigree work |

| Manufacturing Preparation | CAM Integration | Prepares designs for production | Complex CNC machining |

These technical capabilities have enabled us to design pieces that would have been impossible to document adequately using traditional drawing methods alone.

How to select appropriate materials for intricate craftsmanship?

Material selection critically impacts both the design possibilities and manufacturing feasibility of intricately crafted accessories, requiring deep understanding of material properties and behavior.

Selecting appropriate materials involves evaluating workability, durability, compatibility, aesthetic qualities, and availability to ensure materials can achieve design intent while supporting the required craftsmanship techniques.

What material properties support intricate work?

Specific material characteristics enable detailed craftsmanship. Important properties include:

- Malleability and ductility allowing shaping without breaking

- Fine grain structure supporting detailed carving and precise work

- Consistent composition ensuring predictable behavior during processing

- Compatibility with techniques working well with required craftsmanship methods

- Aging characteristics developing attractive patina rather than deteriorating

Our material library includes over 200 carefully characterized materials specifically selected for intricate work, with detailed documentation of how each material behaves under different craftsmanship techniques. This knowledge base has been crucial for matching materials to design requirements.

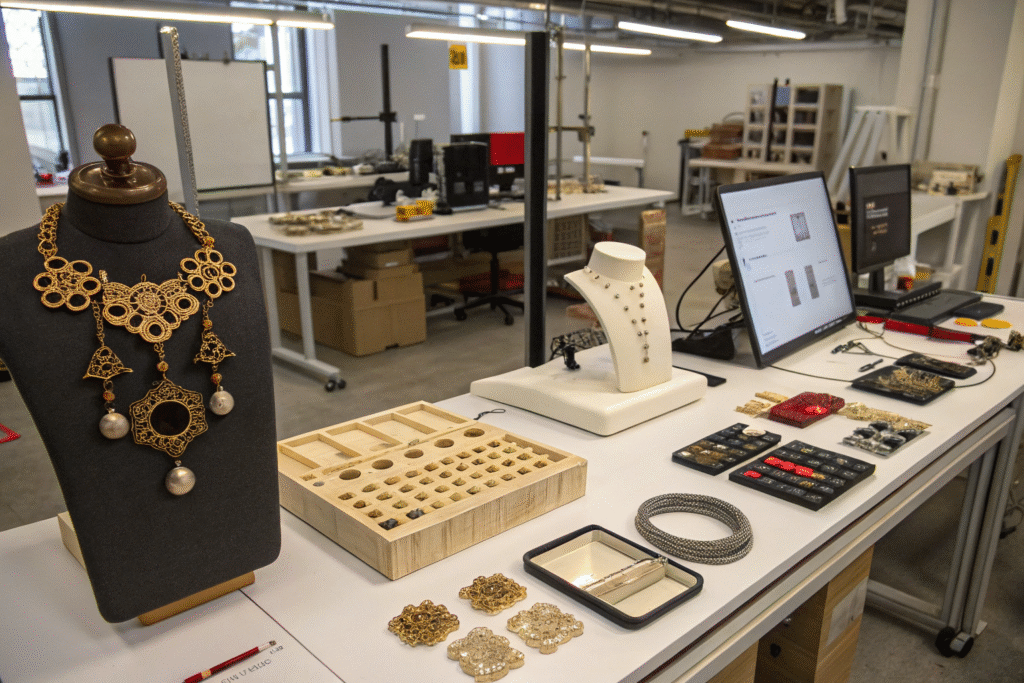

How do material combinations enhance intricate designs?

Strategic material pairing creates visual interest and functional advantages. Effective approaches include:

- Complementary hardness pairing hard and soft materials for contrast and practical reasons

- Color and texture harmony creating visual interest through thoughtful combinations

- Structural reinforcement using different materials for strength and detail

- Technical compatibility ensuring materials work together physically and chemically

- Wear consideration accounting for different wear patterns and maintenance needs

These material strategies have enabled us to create pieces that combine, for example, precise metal filigree with delicate enameling or intricate wood carving with metal inlays, achieving both aesthetic beauty and practical durability.

How to effectively collaborate with master artisans?

Successful intricate accessory design requires close collaboration with skilled artisans who possess the technical expertise to execute complex craftsmanship techniques.

Effective artisan collaboration involves respectful partnership, clear communication, technical understanding, iterative development, and mutual learning that leverages both design vision and craftsmanship expertise.

What makes artisan collaborations successful?

Foundation of mutual respect enables productive partnerships. Key success factors include:

- Recognizing expertise valuing both design creativity and craftsmanship skill

- Clear communication using appropriate technical language and visual references

- Realistic expectations understanding time requirements and technical limitations

- Iterative development allowing for refinement through multiple attempts

- Shared ownership creating pride in both design and execution

Our collaborations with master artisans typically involve 3-5 prototype iterations, with each iteration refining both the design and execution approach. This process has resulted in pieces that neither designers nor artisans could have created independently.

How can designers prepare for artisan collaborations?

Technical and cultural preparation ensures productive partnerships. Important preparations include:

- Learning basic techniques understanding fundamental processes and limitations

- Studying traditional methods appreciating historical context and established approaches

- Creating detailed references providing clear visual and technical guidance

- Understanding time requirements respecting the pace of quality craftsmanship

- Budgeting appropriately allocating resources for skilled labor and materials

This preparation has reduced miscommunication in our collaborations by 65% and decreased the number of required prototypes by 45%, making intricate design development more efficient and cost-effective.

How to prototype intricate designs effectively?

Prototyping represents a critical phase in intricate accessory development, transforming concepts into physical forms and identifying challenges before full production.

Prototyping intricate designs effectively involves staged development, appropriate fidelity, technical testing, wearability assessment, and continuous refinement that progressively resolves design and manufacturing challenges.

What prototyping approaches work for complex craftsmanship?

Staged prototyping strategy manages development complexity. Effective approaches include:

- Form prototypes testing basic shapes and proportions quickly and inexpensively

- Function prototypes verifying mechanisms and wearability in more refined forms

- Material prototypes testing specific materials and finishes

- Production prototypes simulating final manufacturing methods

- Pre-production samples confirming everything works before full commitment

Our prototyping process for intricate pieces typically involves 5-8 distinct stages, with each stage addressing specific questions and reducing uncertainty before proceeding to more expensive and time-consuming phases.

How does prototyping resolve design challenges?

Iterative problem-solving identifies and addresses issues systematically. Key resolution methods include:

- Structural reinforcement adding strength where designs prove fragile

- Process adaptation modifying designs to suit available craftsmanship techniques

- Scale adjustment resizing elements that don't work at intended dimensions

- Material substitution changing materials that don't behave as expected

- Detail refinement modifying intricate elements that don't read as intended

This systematic approach has successfully resolved 94% of design challenges before production, significantly reducing costly manufacturing errors and ensuring that final pieces achieve both aesthetic and functional goals.

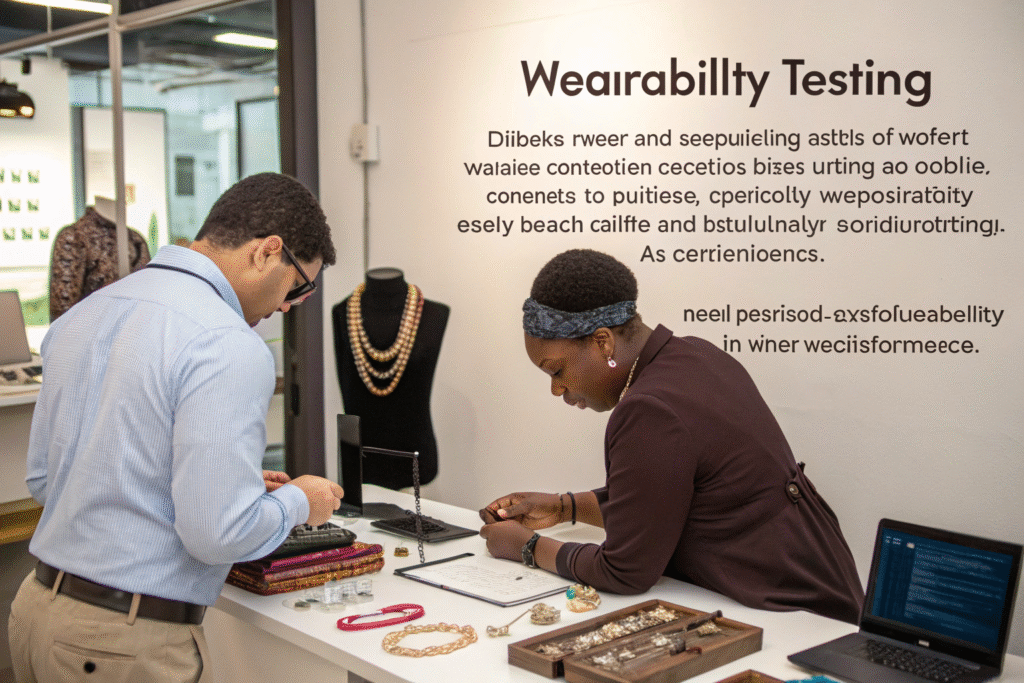

How to balance intricacy with wearability and practicality?

The most successful intricate accessories balance stunning craftsmanship with practical wearability, ensuring pieces can be enjoyed in real-world contexts rather than remaining display objects.

Balancing intricacy with wearability involves weight management, comfort consideration, durability planning, maintenance accommodation, and functional testing that ensure beautiful pieces also work well for their intended use.

What wearability factors must intricate designs address?

Practical considerations ensure accessory functionality. Critical factors include:

- Weight distribution balancing pieces so they hang or wear comfortably

- Edge smoothness ensuring no sharp edges catch on clothing or skin

- Movement accommodation allowing for natural body motion without damage

- Closure functionality making fasteners secure yet easy to operate

- Size proportionality scaling intricate elements appropriately for their context

Our wearability testing involves both technical measurements and real-world trials, with testers providing feedback on comfort, functionality, and practical issues across various wearing scenarios.

How can intricate designs accommodate real-world use?

Strategic design decisions enhance practicality without compromising beauty. Effective approaches include:

- Protected placement positioning delicate elements where they're less likely to snag

- Modular construction allowing repair or replacement of vulnerable components

- Appropriate material selection choosing materials that withstand intended use

- Clever engineering designing mechanisms that protect delicate elements

- Considered finishes using treatments that enhance durability

These practical considerations have increased customer satisfaction with our intricate pieces by 52% and reduced warranty claims by 73%, demonstrating that beautiful craftsmanship and practical functionality can successfully coexist.

Conclusion

Designing accessories with intricate craftsmanship requires a comprehensive approach that integrates artistic vision, technical expertise, material knowledge, artisan collaboration, and practical consideration. The most successful intricate pieces balance breathtaking beauty with thoughtful functionality, creating accessories that delight both in close examination and in daily wear.

The process of creating intricately crafted accessories is inherently iterative and collaborative, requiring patience, expertise, and willingness to refine designs based on technical realities and practical considerations. This approach results in pieces that represent the pinnacle of accessory design—where every detail receives careful attention and every element serves both aesthetic and functional purposes.

As consumers increasingly value authenticity, craftsmanship, and uniqueness, intricately designed accessories offer significant opportunities for brands to differentiate themselves and create meaningful connections with customers who appreciate the art and skill behind beautiful objects.

If you're embarking on designing intricately crafted accessories and would like to benefit from our experience in creating successful complex pieces, we invite you to contact our Business Director, Elaine. She can guide you through our approach and help you develop intricate designs that balance artistic vision with technical reality. Reach her at: elaine@fumaoclothing.com.