Creating a professional tech pack for baseball caps is the most critical step between a great design idea and a perfectly manufactured product. Think of it as the universal blueprint and instruction manual for your factory. A clear, comprehensive tech pack eliminates guesswork, prevents costly errors, and ensures the final caps match your vision exactly. Without it, you're relying on verbal descriptions and hope, which is a major risk in global manufacturing.

A tech pack for baseball caps is a detailed digital document containing all technical specifications, visual references, and material instructions needed to produce your cap. Its core purpose is to provide absolute clarity. A complete pack includes a technical flat sketch with callouts, a detailed measurement spec sheet, a full Bill of Materials (BOM), construction notes, and packaging instructions. For a standard baseball cap, you should expect to define over 15 critical measurements and list 10-15 individual components.

This guide will walk you through each essential section. By the end, you'll know how to build a tech pack that empowers your manufacturer—like us at Shanghai Fumao Clothing—to execute your design efficiently and accurately, from first sample to bulk production.

What Are the Essential Components of a Baseball Cap Tech Pack?

A tech pack is not a single page; it's a multi-section dossier. Each part answers specific questions for the production team. The foundational components are: Technical Sketches & Design Overview, The Measurement Spec Sheet, and the Bill of Materials (BOM). These three sections communicate the "what," the "size," and the "parts." Getting these right is 80% of the battle. They translate your aesthetic concept into a technical reality that pattern makers, cutters, and sewing line operators can understand and follow without needing to ask you questions.

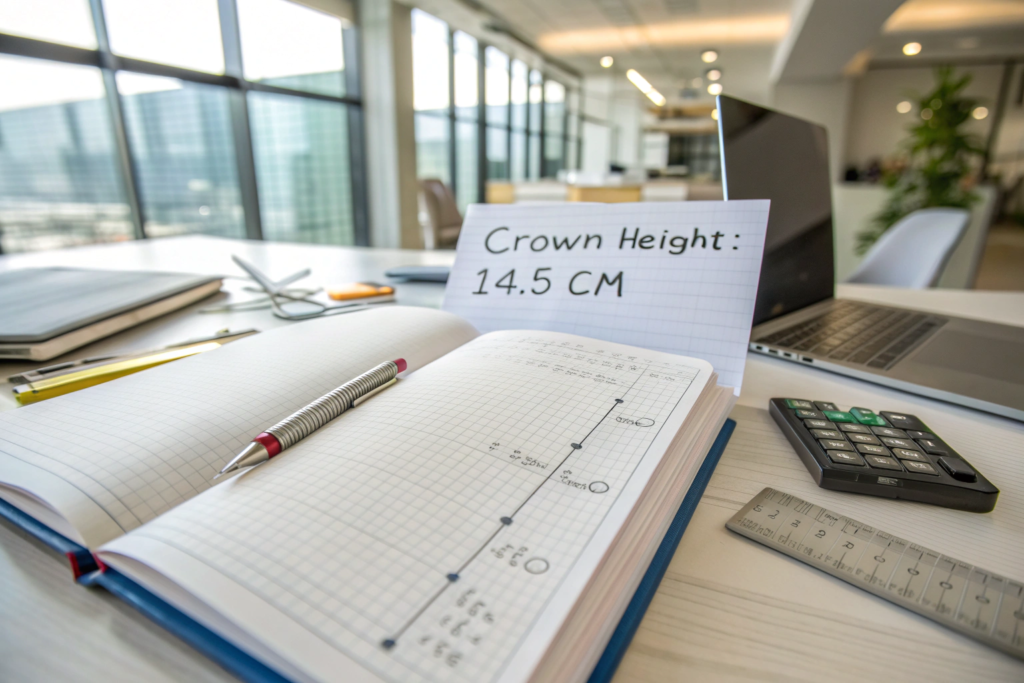

Investing time here pays off dramatically. A detailed tech pack reduces the sample revision cycle—instead of 4 rounds of comments like "crown looks too tall," you can specify "Crown Height: 14.5 cm" from the start. It also forms the basis of your quality control checklist later. For manufacturers, a good tech pack signals a professional and prepared client, which allows us to provide a more accurate quote and faster turnaround time.

Why are technical flats and construction details the visual blueprint?

Technical flats are 2D, black-and-white drawings of your cap from every necessary angle: front, side, back, and sometimes top or bottom. They are not moody marketing images; they are precise line drawings. Their job is to show the construction:

- Seam Lines: Where each panel is stitched together.

- Stitching Type: Indicate topstitching versus seam stitching.

- Component Placement: The exact location of the button, eyelets, buckle, and any patches.

- Hardware & Trims: Clearly call out closures (snapback, strapback, fitted), buckles, and rivets.

You should annotate these flats with numbers or letters that correspond to the BOM and measurement sheet. For example, callout "A" on the sweatband in the sketch links to "Item A: Sweatband" in the BOM.

What must be included in the measurement specification sheet?

This is arguably the most important page. It's a table listing every single critical dimension of the cap. It must include:

- Head Circumference: The internal measurement at the base of the cap (e.g., 58 cm for a size M).

- Crown Height: Measured from the seam at the base to the top center.

- Visor Length & Width: The projection and span of the brim.

- Visor Pitch: The angle/curvature of the brim.

- Panel Dimensions: The width and height of each of the six (or five) crown panels.

- Sweatband Depth.

All measurements must be in consistent units (centimeters are industry standard), clearly state which size they correspond to (if offering multiple), and indicate the tolerance (e.g., 58cm ± 0.5cm). Providing a simple diagram with measurement lines labeled can prevent massive misunderstandings.

How to Specify Materials and Trims in the Bill of Materials (BOM)?

The Bill of Materials is your ingredient list. It details every single item that goes into making the cap, down to the thread. An incomplete BOM is a leading cause of production delays and cost overruns, as last-minute material sourcing is expensive. For a basic structured baseball cap, you will have items for the crown, visor, sweatband, closure, and branding.

A professional BOM is a spreadsheet. Each row is a unique component, and columns provide specific data. Essential columns are: Item # (matching sketch callouts), Component Name, Material Description, Supplier/Quality Reference, Color (Pantone Code), Quantity Used per Cap, and Notes. For key fabrics like the main crown twill, you should attach a physical fabric swatch to the initial tech pack submission. This gives the factory a tactile reference for weight, handfeel, and color that a digital file cannot.

Why is fabric composition and weight specification non-negotiable?

Simply writing "cotton" is not enough. You must specify the precise composition and weight, as this dictates cost, durability, and how the cap is manufactured. For example:

- Crown Fabric: "100% Cotton Twill, 8oz/yd², Pre-shrunk."

- Back Panels/Mesh: "100% Polyester Mesh, 120 GSM."

- Sweatband: "90% Cotton, 10% Polyester Terry Loop, 220 GSM." (The terry loop provides absorbency).

Weight (in ounces or grams per square meter) directly affects the cap's structure and seasonality. A 6oz fabric is lighter for summer, while an 8oz is sturdier. For performance caps, you might specify moisture-wicking polyester or organic cotton. As a manufacturer, we use this info to source the exact fabric or propose equivalent alternatives from our network if needed.

How do you accurately detail trims, branding, and color?

Trims are the small parts with a big impact. Your BOM must detail:

- Closure: "Plastic Snapback with 4-snap buttons, matte black finish." or "Leather Strap with antique nickel buckle."

- Button: "Matching plastic button, 1.1cm diameter."

- Eyelets: "Metal eyelets, 4mm inner diameter, nickel color."

- Stitching Thread: "Polyester core thread, color-matched to crown."

For branding, this section is vital. Specify: - Embroidery: Provide high-resolution, vector artwork (

.aior.eps). Specify the stitch type (satin, fill), thread count (e.g., 10,000 stitches for a logo), and Pantone thread colors. - Patch/Label: Specify woven, printed, or leather. Provide artwork and exact dimensions (e.g., "Woven care label, 5cm x 2cm"). Indicate its placement with a measurement from a fixed point (e.g., "Centered on sweatband, 2cm from bottom edge").

What Additional Information Ensures Perfect Execution?

Beyond the core three sections, a truly bulletproof tech pack includes information on packaging, labeling, and quality benchmarks. This is what separates an okay pack from an excellent one. It tells the factory how to finish, present, and ensure the quality of your product. It also covers logistical details that affect shipping and receiving.

This section often includes Packing Instructions (how each cap is folded, if polybags are used, how many go in an inner box), Labeling (placement of size tags, price tags, hangtags), and Shipping Mark requirements (what must be printed on the master carton box). Furthermore, it should reference the Quality Standards you expect, which can be based on general industry practices or your own specific checklist (e.g., "All stitches must be even with no loose threads," "Visor must be symmetrical").

How do packing and labeling instructions finalize the product?

Clear packing instructions prevent your caps from arriving crushed or disheveled. You need to specify:

- Folding Method: The industry-standard fold for baseball caps.

- Internal Support: Whether a paper form or tissue is inserted to maintain the crown shape.

- Polybag: The size and type of protective plastic bag for each cap.

- Hangtags & Labels: How they are attached (plastic anchor, string) and their position.

- Carton Box: The quantity per inner box and master carton, plus the carton's dimensions and strength (e.g., "200#/ECT-32 corrugated box"). This is crucial for your logistics planning and cost.

What quality benchmarks and reference samples should you provide?

Your tech pack should point to a quality standard. This can be as simple as stating, "Quality must meet Shanghai Fumao Clothing Standard AQL Level II for inspection," which is a statistically defined sampling plan. You can also list specific checks:

- "All embroidered logos must be centered within a 2mm tolerance."

- "Color must match approved lab dip within Delta E < 2 under D65 light."

- "Visor must be rigid with no warping."

Most importantly, you must provide a reference sample or "golden sample." This is a physical cap that has been approved in every detail. The factory will match their production to this sample. Mark it with a permanent tag, sign off on it, and keep one for yourself. It is the ultimate arbiter in any quality dispute.

How to Define Details for Manufacturing?

Defining precise manufacturing details for baseball caps is the cornerstone of ensuring product consistency, meeting quality standards, and avoiding costly production errors. These details must cover every tangible component and production step, leaving no room for ambiguity—from the fabric’s texture to the stitch density, and from hardware dimensions to assembly sequences.

What Information Must Be Included in Fabric Specifications?

Fabric specifications detail every textile used in the baseball cap, ensuring manufacturers source materials that match quality, texture, and performance requirements.

How to Specify Hardware and Accessories for Baseball Caps?

Hardware and accessories are small but critical components that impact the cap’s functionality and aesthetics—their specifications must be detailed in the tech pack.

Conclusion

Creating a thorough tech pack is an act of precision and foresight. It transforms your creative vision into a set of unambiguous, actionable instructions for your manufacturing partner. A great tech pack—with detailed flats, exact measurements, a comprehensive BOM, and clear packing instructions—is the single best tool to ensure on-time delivery of a quality product that matches your design.

While it requires an upfront investment of time and attention, this effort saves immense time, money, and frustration later by minimizing errors and revisions. It establishes you as a professional and builds a stronger, more efficient partnership with your manufacturer.

If you are developing a new baseball cap line and need expert guidance in finalizing your tech pack or translating your ideas into a production-ready format, our team is here to help. Contact our Business Director Elaine at elaine@fumaoclothing.com to discuss how we can support your project from tech pack review through to flawless bulk production.