The fashion accessories industry, particularly hats and scarves manufacturing, has traditionally relied on skilled manual labor with production capacity limited by human speed, precision, and endurance. As consumer demand for variety, customization, and fast delivery increases, traditional manufacturing methods struggle to scale efficiently. Automation addresses these challenges by transforming production from human-paced to technology-optimized processes.

Automation dramatically improves hats and scarves production capacity through 24/7 operation, consistent high-speed production, reduced material waste, minimized human error, and seamless scalability.These improvements collectively increase output while maintaining or enhancing quality standards, enabling manufacturers to meet growing market demands without proportional increases in costs or resources.

Let's examine the specific ways automation enhances production capacity across different aspects of hats and scarves manufacturing.

How does automation enable continuous production operation?

Traditional manufacturing operates within human work schedules, with natural breaks, shift changes, and fatigue-related slowdowns that limit production hours. Automation transforms this constraint by enabling 24/7 operation without the physical limitations of human workers, fundamentally expanding potential production capacity.

Continuous operation represents perhaps the most straightforward capacity improvement from automation.

What specific operational hours improvement does automation provide?

Uninterrupted production cycles allow manufacturing to continue outside standard working hours, effectively multiplying productive capacity. Our implementation of automated knitting for scarves increased operational hours from 16 hours daily (across two shifts) to 24 hours, resulting in a 50% increase in potential output without additional human resources. This extended operation has been particularly valuable during peak seasons when demand exceeds normal production capacity.

How does automation maintain consistent speed regardless of duration?

Constant operation parameters ensure production speed remains optimal throughout operation, unlike human workers who experience performance variation due to fatigue. Our automated hat molding systems maintain consistent cycle times of 42 seconds per hat regardless of how long the system has been operating. This performance consistency has eliminated the 15-20% production speed reduction that typically occurred during the final hours of manual shifts due to worker fatigue.

How does automation increase production speed?

Human-paced manufacturing has inherent speed limitations determined by physical capability, safety considerations, and quality maintenance. Automated systems operate at precisely calibrated speeds that typically exceed human capabilities while maintaining accuracy. The speed advantages accumulate across multiple production stages.

The cumulative effect of accelerated individual processes significantly increases overall production capacity.

What specific speed improvements occur in knitting and weaving?

High-velocity automated looms and knitting machines produce fabric at speeds impossible for manual operation. Our automated scarf knitting systems operate at 1,200 courses per minute compared to approximately 200 courses per minute on manual machines, representing a 6x speed increase while actually improving stitch consistency. This accelerated fabrication has transformed our ability to produce basic scarf styles in high volumes while freeing skilled workers for complex custom orders.

How does automation accelerate cutting and assembly?

Simultaneous multi-operation processing enables automated systems to perform multiple tasks in parallel rather than sequentially. Our automated hat production cell performs cutting, shaping, and preliminary assembly in a single integrated process that takes 3.2 minutes compared to the 8.5 minutes required for manual sequential processing. This parallel processing has been particularly valuable for complex hat designs with multiple components that previously required extensive manual handling between operations.

How does automation enhance material utilization and reduce waste?

Material costs represent a significant portion of total production expenses for hats and scarves. Traditional manual processes often generate substantial waste through imprecise cutting, handling errors, and quality issues. Automation improves material utilization through precision operations and optimized material management.

Reduced waste effectively increases production capacity by making more products from the same material input.

How does automated cutting optimize material usage?

Computer-optimized nesting algorithms arrange pattern pieces to maximize material utilization, significantly reducing waste compared to manual layout. Our implementation reduced fabric waste for scarf production by 38% through optimal placement of pattern pieces and elimination of cutting errors. This material efficiency effectively increases production capacity by creating more products from the same material input, particularly valuable for expensive materials like cashmere, silk, and specialty wools.

What role does precision manufacturing play in waste reduction?

Consistent execution accuracy minimizes errors that lead to rejected products and material waste. Our automated hat manufacturing system has reduced material-related defects by 87% through precise control of cutting, sewing, and assembly operations. This quality consistency has been particularly impactful for complex designs where manual errors previously resulted in significant rework and material loss.

How does automation improve scalability and flexibility?

Traditional manufacturing faces challenges in scaling production capacity quickly to meet fluctuating demand. Adding human capacity requires time-consuming recruitment, training, and facility adjustments. Automated systems offer more responsive scalability through modular expansion and flexible operation parameters.

The ability to quickly scale production represents a crucial capacity advantage in seasonal and trend-driven markets.

How does modular automation enable rapid capacity expansion?

Scalable production cells can be added incrementally to increase capacity without major facility reorganization. Our modular scarf printing system allows us to add capacity in 25% increments by integrating additional printing modules, with each new unit becoming operational within 3 days versus the 4-6 weeks required to recruit and train additional printing staff. This incremental scalability has transformed our ability to respond to unexpected demand surges without maintaining expensive excess capacity during normal periods.

What flexibility advantages does automation provide for product variations?

Quick changeover capabilities enable automated systems to switch between different hat and scarf designs with minimal downtime. Our automated systems can change between different scarf patterns in 8-12 minutes compared to the 45-60 minutes required for manual reconfiguration. This rapid adaptability has increased our effective capacity by enabling more frequent product variations without significant production interruptions, particularly valuable for fast-fashion segments with short product lifecycles.

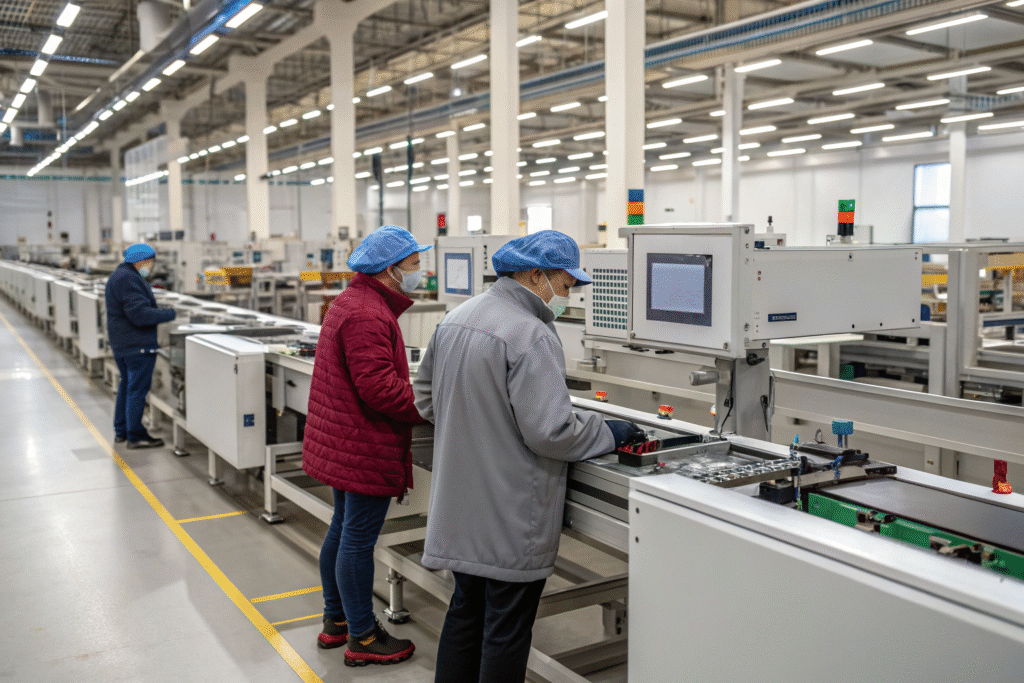

How does automation enhance labor productivity?

While automation reduces direct labor in some areas, it dramatically enhances the productivity of remaining human workers by freeing them from repetitive tasks and enabling focus on higher-value activities. This reallocation of human effort creates additional capacity improvements beyond the direct effects of automation.

The synergy between automated systems and human skills creates productivity multipliers.

How does automation change workforce allocation?

Skill-focused redeployment moves human workers from repetitive manual tasks to supervision, programming, maintenance, and quality control roles. Our automation implementation enabled each operator to oversee 3-4 automated systems simultaneously, increasing output per operator by 280% while actually improving working conditions. This productivity multiplication has addressed labor shortage challenges while increasing total production capacity without proportional workforce expansion.

What training benefits does automation provide?

Consistent process execution creates predictable production outcomes that simplify training and reduce skill requirements for certain operations. Our automated hat finishing system reduced training time from 6 weeks to 3 days by standardizing complex processes that previously required extensive skill development. This accelerated competency has improved our capacity to scale operations quickly during peak periods by reducing our dependence on highly skilled manual workers.

Conclusion

Automation fundamentally transforms hats and scarves production capacity by enabling continuous operation, increasing speed, reducing waste, enhancing scalability, and improving labor productivity. These improvements collectively create manufacturing systems that can produce more products, of higher consistency, with greater efficiency, and with more responsive adaptability to market changes.

The capacity benefits extend beyond simple output increases to include the ability to handle greater product variety, accommodate customization requests, and respond to volatile demand patterns. As automation technologies continue to advance and become more accessible, their role in capacity enhancement will likely expand, further transforming manufacturing capabilities in the fashion accessories industry.

If you're interested in implementing automation to improve your hats and scarves production capacity or want to partner with a manufacturer that has advanced automation capabilities, we invite you to contact our Business Director, Elaine. She can discuss our automation approaches and how they deliver superior production capacity. Reach her at: elaine@fumaoclothing.com.