Global accessory markets demand more than fashion—they demand compliance. For brands and buyers in the U.S., Europe, and beyond, working with a supplier who can navigate certifications, testing, and customs documentation is the difference between on-time launch or blocked shipments. If you’ve been burned by non-compliant goods before, you know how costly mistakes can be.

AceAccessory ensures product compliance across global markets by implementing strict material sourcing standards, third-party testing, in-house audits, and continuous monitoring of international regulations.

As the founder of AceAccessory, I’ve seen firsthand how regulatory landscapes evolve and how buyer confidence grows when backed by verifiable, consistent compliance. Let me walk you through how we do it—and how you can benefit.

What Certifications Are Required for Different Global Markets?

Not every product needs the same certificates. But every market has standards—and we make it our mission to meet them.

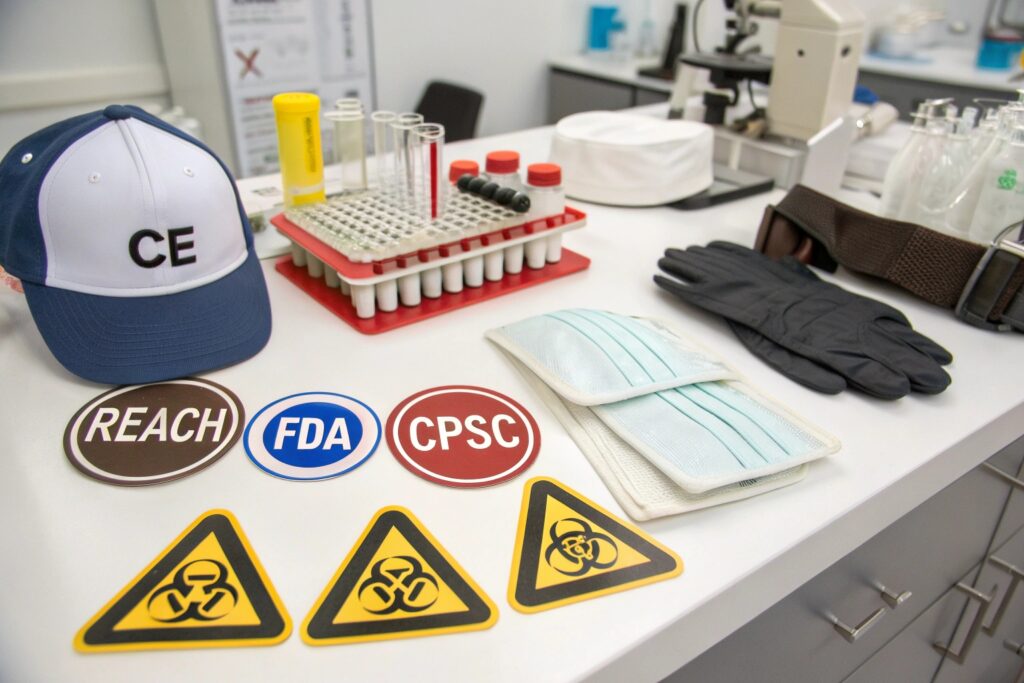

Different countries require specific product certifications such as CE in Europe, FDA in the U.S., and REACH for chemicals and materials.

What Does Europe Require for Accessory Compliance?

The European Union mandates the CE mark for many wearable products that have safety implications, such as UV-protective sunglasses or children's gloves. Beyond CE, the REACH regulation governs chemical content in materials, particularly plastics, metals, and dyes.

We routinely test our products through authorized EU labs to obtain CE documentation and REACH compliance reports, particularly for belts with coated hardware and scarves made from synthetic fibers.

What About U.S. Import Standards?

For the American market, different agencies oversee product categories. The CPSC manages general consumer safety, especially for children's accessories, requiring testing for choking hazards and flammability. Apparel-related products often require a General Certificate of Conformity (GCC). Products like drinkware or food-contact items must meet FDA standards.

We help our U.S. clients by preparing these certificates and offering pre-shipment test reports via SGS or TÜV Rheinland.

How Does AceAccessory Ensure Raw Material Safety?

Compliance begins before stitching and sewing—it starts with the raw materials.

AceAccessory controls input quality by sourcing certified raw materials, conducting in-house safety audits, and maintaining long-term supplier evaluation systems.

How Do You Verify Fabric and Plastic Safety?

We require all fabric and plastic suppliers to submit updated OEKO-TEX® or REACH-compliant certifications. For PU leather belts, we screen for phthalates and heavy metals. Every incoming batch undergoes sampling inspection before entering our production lines.

We maintain a material compliance dashboard that tracks testing frequency and re-certification dates. Our lab team checks dye fastness, migration of chemicals, and durability thresholds per ISO 105 and ISO 8124 standards.

Are Hardware Components Like Buckles and Zippers Tested?

Yes, especially for European markets where metal items often trigger REACH evaluations. We test for nickel release, cadmium, and lead content. We also pressure-test fasteners for strength and corrosion. Many of our belt buckles come from audited suppliers with pre-tested materials.

Our hardware tracking system flags high-risk items and ensures only approved components make it into production. If a supplier fails twice in one quarter, we suspend their approval status.

What Is AceAccessory’s Internal Quality Control Process?

Compliance isn’t just paperwork—it’s an embedded system.

We use a triple-layer QC process including inline inspections, AQL sampling, and documentation audits for every export order.

How Are Products Inspected Before Shipment?

Each production line includes inline QC checkpoints. Our team monitors stitching, sizing, trims, and packaging. Once a batch is ready, we perform AQL sampling inspections based on client standards—typically AQL 2.5 or lower.

We tag defects immediately and classify them by severity. Final shipments are packed only after passing all parameters. For buyers who require video or remote inspections, we offer real-time QC livestreams via WeChat or Zoom.

What Role Does Documentation Play?

Every shipment is backed by a QC report, certificate copy, and packing list. For sensitive markets, we also submit GCC files or CE declarations as needed. These files are organized per customer and archived digitally for 24/7 retrieval.

We also provide QR codes on cartons linking to inspection result dashboards—this helps large chains and warehouses verify inbound quality at a glance.

How Does AceAccessory Stay Updated on Global Regulations?

Regulations evolve. What passed last year might fail this year. Staying compliant means staying informed.

Our compliance team tracks global updates, works with testing labs, and retrains factory staff to meet changing market rules.

How Do You Monitor Changes in Compliance Laws?

We subscribe to updates from ECHA, CPSC, and CustomsInfo. We also participate in online webinars and trade seminars by SGS and TÜV to interpret upcoming rule changes.

Our team meets monthly to revise test protocols and reissue supplier guidelines. When Europe updated its restricted substances list last year, we notified vendors within 3 days and updated material declarations within the same week.

What Training Does Your Staff Undergo?

Every QC and project manager undergoes quarterly compliance training. Topics include latest REACH chemicals, updated AQL levels, and new tariff codes. Training content is developed with input from our lab partners and regulatory consultants.

New hires shadow inspections for 2 weeks and complete a compliance certification module before joining live projects. We believe compliance is a mindset—not a task.

Conclusion

Compliance isn’t optional—it’s a pillar of global trade. At AceAccessory, we’ve built a compliance system that starts from the fiber and follows through to the shipping label. By controlling inputs, testing processes, auditing outputs, and updating protocols regularly, we help global brands reduce risk, build customer trust, and stay ahead of changing regulations. For U.S. chains, European retailers, and online brands alike, that’s peace of mind worth investing in.