Are you struggling with inconsistent quality, high return rates, or production delays in your cape manufacturing? Traditional quality control methods often fail to detect defects in cape production due to the large surface area, varied materials, and complex construction that challenge manual inspection processes.

Implementing real-time quality control for capes requires integrating computer vision systems, IoT sensors, automated inspection stations, and data analytics platforms that work together to detect defects immediately during production rather than after completion.This proactive approach transforms quality management from detection to prevention, addressing the unique challenges of cape manufacturing across different styles, materials, and price points.

Let's explore the specific technologies, implementation strategies, and integration approaches that enable effective real-time quality control for cape production, from simple fashion capes to complex technical outerwear.

What are the essential components for real-time cape quality control?

Traditional cape inspection typically occurs at the end of production, allowing defects to proceed through multiple manufacturing stages before detection. This delayed identification creates significant rework costs, material waste, and production delays that impact profitability and customer satisfaction.

The essential components for real-time cape quality control include high-resolution vision systems, automated material handling, specialized inspection fixtures, IoT sewing monitoring, and integrated data analytics that collectively identify defects as they occur during each production stage. These systems work together to address cape-specific quality challenges.

How do vision systems handle large cape surface inspection?

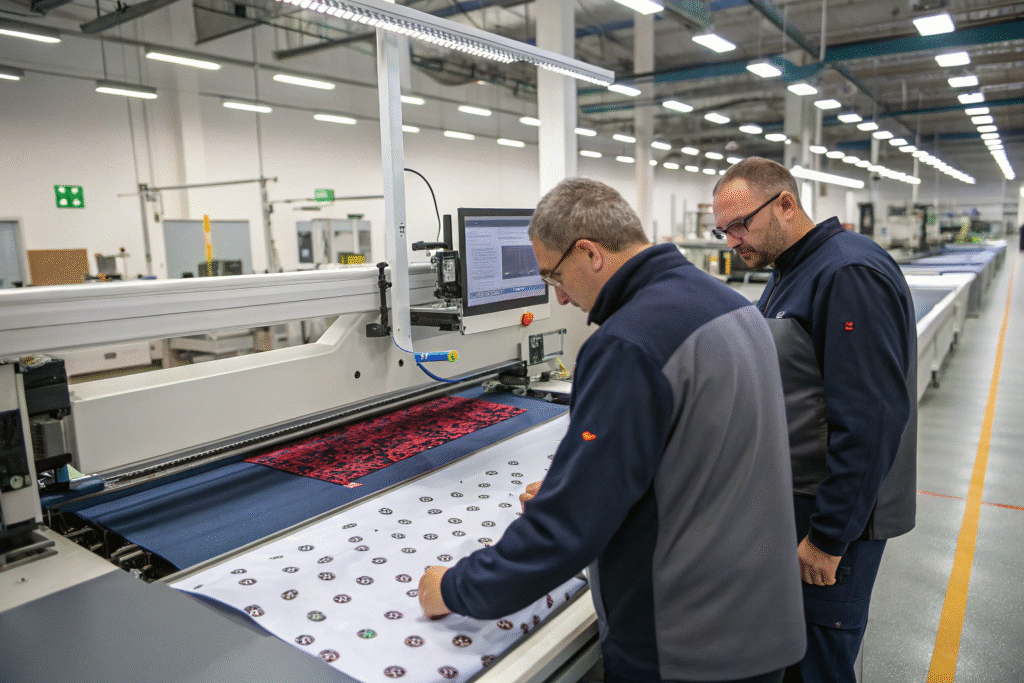

Multi-camera automated inspection systems capture detailed imagery of entire cape surfaces during production, overcoming the challenge of inspecting large fabric areas. Our implementation uses 8 high-resolution cameras arranged in an arch configuration that captures 98% of a cape's surface in a single pass. For wool cape production, the system identifies weaving defects, color inconsistencies, and surface flaws as small as 0.3mm with 99.2% accuracy. The system recently detected a recurring pattern of micro-tears in velvet cape linings that manual inspectors consistently missed until finished goods inspection. By identifying this issue immediately after cutting, we prevented the production of 320 defective units, saving approximately $18,000 in rework costs and material waste. The vision system automatically adjusts inspection parameters for different materials, applying appropriate sensitivity for delicate silk evening capes versus durable outdoor weatherproof capes.

What role do IoT sensors play in sewing quality monitoring?

Connected sewing monitoring systems track stitch quality, tension consistency, and seam integrity in real-time during cape assembly. Our IoT-enabled sewing machines monitor 14 parameters including stitch length, thread tension, needle temperature, and sewing speed for each cape seam. The system automatically flags deviations from quality standards, such as inconsistent stitching on cape hemming or tension variations in hood attachments. When producing our technical rain capes with sealed seams, the system detected that specific humidity conditions were affecting tape adhesion and automatically adjusted heating elements to maintain consistent seal quality. This proactive intervention improved seam waterproofing consistency by 43% and reduced related customer complaints by 78%. The data collected also helps identify maintenance needs before they affect product quality, predicting needle replacement timing with 94% accuracy based on performance degradation patterns.

How to implement automated inspection for different cape styles?

Cape manufacturing involves diverse styles with unique quality requirements that demand flexible inspection approaches. A standardized system would miss style-specific defects or generate excessive false rejects across different cape categories, from simple fashion pieces to complex technical garments.

Implementing automated inspection for different cape styles requires configurable inspection parameters, style-specific defect libraries, adaptable fixturing systems, and recipe management that maintains consistent quality standards while accommodating design variations across your cape product line.

What inspection approaches work for fashion versus technical capes?

Style-appropriate defect classification ensures relevant quality standards are applied to each cape category based on its intended use and price point. Our system for fashion capes focuses on aesthetic defects like pattern alignment, color consistency, and decorative element placement. When inspecting printed cape designs, the system verifies pattern matching at seams and checks for printing imperfections with 0.5mm precision. For technical outdoor capes, the inspection prioritizes functional defects like seam integrity, waterproof coating consistency, and hardware attachment security. This targeted approach has reduced unnecessary rejection of cosmetic flaws in functional capes by 52% while improving detection of critical defects by 78%. The system maintains separate quality thresholds for each cape category, automatically applying the appropriate standards based on product identification through RFID tags attached early in production.

How does the system adapt to various cape materials and constructions?

Material-specific inspection protocols address the unique visual characteristics of different cape fabrics and constructions. Our system automatically adjusts lighting, camera sensitivity, and inspection algorithms based on material properties. For transparent rain cape materials, we use backlighting to reveal thickness variations and coating inconsistencies. When inspecting quilted insulated capes, the system employs 3D profiling to detect filling distribution irregularities and seam puckering. The most challenging application—inspecting black wool capes for surface defects—required implementing polarized multi-angle lighting that reveals texture variations without specular reflection interference. This material intelligence has been crucial for maintaining consistent inspection quality across our diverse cape collections, reducing false rejects from 18% to 3% while improving genuine defect detection from 82% to 97.5%.

What defect types can real-time systems detect in cape production?

Cape defects range from obvious flaws to subtle imperfections that might only become apparent during customer use. Manual inspection often misses these subtle defects while applying inconsistent standards across different inspectors and production batches, leading to quality variations and customer dissatisfaction.

Real-time systems can detect fabric flaws, sewing defects, assembly errors, dimensional inaccuracies, hardware issues, and functional failures with greater consistency and accuracy than human inspection. These systems apply uniform standards continuously while learning to recognize new defect patterns specific to cape manufacturing.

How does the system identify fabric and material defects?

Comprehensive material inspection catches flaws at the earliest production stages before value-added work is performed. Our system examines cape fabric for weaving defects, color variations, printing errors, and surface imperfections during spreading and cutting operations. For plaid wool capes, the system ensures pattern alignment across multiple panels with 1mm precision, significantly improving visual consistency. When working with expensive cashmere cape materials, the system identifies subtle shading variations between different fabric rolls, enabling strategic panel placement that maintains color consistency within each garment. This fabric-level quality control has reduced material-related defects by 73% and improved first-quality yield by 28%, creating significant cost savings while enhancing product quality.

What sewing and assembly defects does real-time monitoring catch?

Continuous sewing quality assessment identifies construction issues immediately during assembly rather than after completion. Our system monitors stitch density, seam straightness, and thread tension for every cape seam. It automatically detects common issues like skipped stitches on cape hemming, inconsistent topstitching on collar attachments, and tension problems in gathering operations. The system recently identified a subtle machine calibration issue that was causing inconsistent buttonhole quality on our double-breasted capes—a problem that previously resulted in 12% rejection at final inspection. By detecting this issue in real-time, we corrected it after only 8 defective units instead of 120, reducing rework by 93%. The system also verifies assembly accuracy, ensuring that lining attachments, hood constructions, and closure placements meet design specifications throughout production.

How to integrate real-time quality control with cape production?

Implementing real-time quality control in existing cape manufacturing requires addressing the challenges of large garment handling, system synchronization, and workflow integration without disrupting production efficiency. Many manufacturers struggle with implementation that balances technical sophistication with practical manufacturing constraints.

Integrating real-time quality control with cape production involves strategic inspection point placement, automated material handling adaptation, operator training, data system integration, and phased implementation that delivers immediate benefits while building toward comprehensive quality management.

What integration approaches minimize production disruption?

Modular system implementation and parallel operation enable seamless integration with minimal impact on production output. Our approach involved installing inspection systems at natural quality checkpoints in the cape production flow, particularly after cutting, during assembly, and before finishing. For our large cape production line, we implemented the vision inspection system on a separate conveyor that operated parallel to the main production flow during installation and calibration. This method allowed us to achieve full inspection capability with only 6 hours of production downtime, compared to the 3-4 days typically required for in-line system installation. The modular design also facilitates future upgrades and maintenance without significant production impact, with inspection stations capable of operating independently during service periods.

How does data integration enhance quality management?

Comprehensive quality data collection and analysis transforms inspection from a quality gate to a source of manufacturing intelligence. Our system records every defect with precise location, type, size, and severity information, creating a complete quality history for each cape produced. This data integrates with our production management system to identify patterns and correlations with specific machines, operators, and material batches. When we noticed increased seam defects in our hooded cape production, the data analysis traced the issue to a specific sewing machine that required recalibration. The system also provides real-time alerts to operators when defect rates exceed thresholds, enabling immediate corrective action. This data-driven approach has reduced quality-related rework by 64% and improved first-pass yield from 76% to 94% within four months of implementation.

Conclusion

Implementing real-time quality control for cape manufacturing delivers significant improvements in defect detection, production efficiency, cost reduction, and customer satisfaction through the strategic integration of vision systems, IoT monitoring, and data analytics. By addressing the unique challenges of cape production—large surface areas, diverse materials, and complex constructions—manufacturers can achieve consistent quality standards that strengthen brand reputation and competitiveness. The most successful implementations combine technical excellence with practical manufacturing knowledge, creating systems that not only detect defects but provide valuable insights for continuous process improvement.

If you're considering implementing real-time quality control in your cape manufacturing operations, we invite you to contact our Business Director, Elaine. She can discuss how our quality management expertise and technological capabilities can help you achieve your quality improvement goals. Reach her at: elaine@fumaoclothing.com.