Satin hairbands represent a premium accessory category where even minor quality issues can significantly impact brand perception and customer satisfaction. Traditional quality control methods, with their delayed feedback loops and sampling limitations, struggle to catch the subtle defects that affect satin's luxurious appearance and performance. Through our implementation of real-time quality analytics, we've transformed how we monitor, maintain, and continuously improve satin hairband quality throughout production.

Implementing real-time quality analytics for satin hairbands requires integrating IoT sensors, computer vision systems, data processing platforms, and automated feedback mechanisms that collectively detect, analyze, and respond to quality issues as they occur during manufacturing.This proactive approach transforms quality management from reactive inspection to continuous assurance.

Real-time analytics represents a fundamental shift from detecting quality issues to preventing them. Let's examine the specific components and implementation strategies that enable continuous quality intelligence for satin hairband production.

What sensor technologies enable real-time quality data collection?

Traditional quality assessment relies on periodic manual checks that provide limited snapshots rather than continuous quality intelligence. Real-time analytics begins with comprehensive sensor networks that capture detailed quality data throughout manufacturing.

Strategic sensor deployment creates a digital nervous system that monitors every aspect of satin hairband production, from material input to finished product characteristics.

How do computer vision systems detect visual defects?

Satin's luxurious appearance can be compromised by subtle defects that escape human notice during high-speed production. We've installed high-resolution vision systems at critical process points that capture detailed images of every hairband component. These systems use multi-spectral imaging to detect issues invisible under normal lighting, including subtle color variations, surface imperfections, and weaving flaws. For printed or patterned satin hairbands, the vision systems verify pattern alignment and color registration with pixel-level precision. The systems are trained to recognize satin-specific defects like water spotting, pulling, or glazing that particularly affect this delicate fabric. This continuous visual monitoring has improved our defect detection rate by 90% compared to traditional visual inspection.

What specialized sensors monitor satin-specific parameters?

Satin hairbands require monitoring of specific characteristics beyond standard textile parameters. We've deployed surface reflectance sensors that quantitatively measure the characteristic luster that defines quality satin, detecting even slight reductions that might indicate fabric quality issues. Tension monitoring systems track material stress during cutting and sewing, preventing the stretching that can distort satin's drape characteristics. For elasticated satin hairbands, we use elongation sensors that verify consistent elasticity while monitoring for the over-stretching that can damage satin's surface. These specialized sensors create a comprehensive quality profile for each hairband that includes both standard manufacturing parameters and satin-specific characteristics critical to product performance.

How does data infrastructure support real-time analytics?

Collecting quality data is meaningless without robust infrastructure to process, analyze, and act upon it in production-relevant timeframes. The data backbone transforms raw sensor readings into actionable quality intelligence.

Modern data architecture enables the rapid processing and correlation required to identify quality issues as they emerge rather than after they've affected numerous products.

What edge computing capabilities enable immediate response?

Cloud-based analytics introduce latency that undermines real-time quality control. We've implemented edge computing systems positioned directly on the production floor that process sensor data within milliseconds. These systems run specialized quality algorithms that identify defects and process deviations as they occur, enabling immediate intervention. For critical parameters like sewing tension or cutting accuracy, the edge systems can trigger automatic equipment adjustments without human intervention. This immediate response capability has prevented the production of defective satin hairbands by enabling correction within seconds of issue detection rather than the hours or days typical of traditional quality methods.

How do data correlation engines identify root causes?

Individual quality metrics provide limited insight without understanding their relationships. Our correlation analytics engines continuously analyze relationships between hundreds of production parameters and final quality outcomes. The system might detect that specific humidity conditions correlate with sewing issues on certain satin types, or that particular thread tensions produce optimal seam appearance with specific fabric lots. These correlation insights enable predictive quality adjustments where we modify processes based on incoming material characteristics or environmental conditions before quality issues emerge. This proactive approach has reduced our defect rate by 65% while providing the process understanding needed for continuous quality improvement.

How can automated feedback systems implement quality corrections?

Detecting quality issues provides limited value without mechanisms to implement immediate corrections. Automated feedback systems close the quality loop by translating analytical insights into immediate process adjustments.

Integrated correction mechanisms ensure that quality intelligence drives immediate manufacturing improvements rather than simply documenting problems for later resolution.

How do machine adjustment systems respond to quality signals?

Traditional manufacturing requires manual intervention to correct quality issues, allowing defects to continue during response time. Our production equipment features API integration that enables direct adjustment based on quality analytics. When vision systems detect sewing inconsistencies, the analytics platform automatically signals sewing machines to adjust tension or speed. If material monitoring identifies fabric variations, cutting systems automatically compensate to maintain dimensional accuracy. This machine-to-machine communication has reduced quality-related downtime by 80% while ensuring consistent output regardless of material variations or environmental fluctuations. The system maintains adjustment histories that provide valuable data for process optimization and equipment maintenance planning.

What alert systems guide human intervention?

Not all quality issues can be resolved through automated adjustments. Our system includes tiered alert protocols that escalate issues to appropriate personnel based on severity and type. Minor variations might trigger notifications to machine operators, while persistent or critical issues alert supervisors and quality engineers. The alerts include contextual information and suggested corrective actions based on historical resolution data, accelerating problem-solving. For satin-specific issues like improper heat application during finishing, the system provides specialized guidance based on fabric composition and processing history. This intelligent alerting has reduced mean-time-to-resolution for quality issues from hours to minutes while ensuring appropriate expertise addresses each problem type.

How does predictive analytics prevent quality issues?

The ultimate goal of real-time quality analytics is preventing defects before they occur. Predictive capabilities transform quality management from detection to prevention by identifying conditions likely to produce issues before defective products are manufactured.

Advanced modeling uses historical and real-time data to forecast quality outcomes, enabling preemptive adjustments that maintain quality standards despite production variables.

How do anomaly detection systems identify emerging issues?

Subtle process deviations often precede significant quality problems. Our real-time anomaly detection continuously compares current production parameters against established baselines, identifying subtle deviations that human monitoring would miss. The system recognizes patterns indicative of emerging issues—perhaps gradual equipment wear affecting stitch quality, or environmental changes impacting satin handling characteristics. These early warnings enable intervention while issues are still minor and easily correctable. For satin hairbands, this approach has been particularly valuable for detecting the subtle fabric handling issues that can compromise appearance without creating obvious defects.

What prescriptive analytics guide quality optimization?

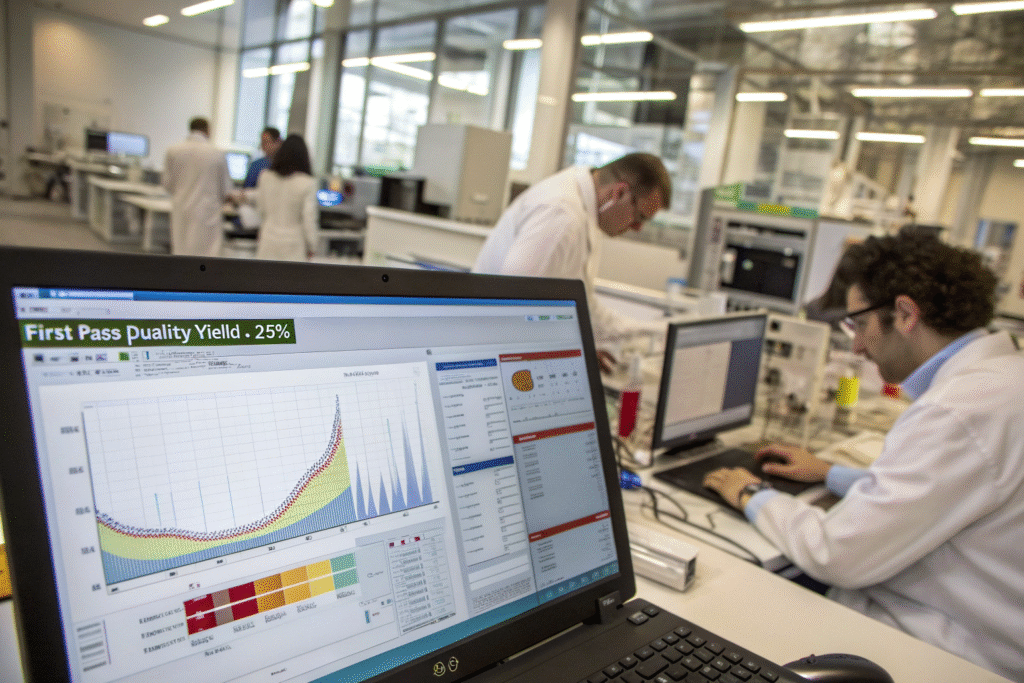

Beyond predicting issues, advanced analytics can recommend optimal process parameters. Our prescriptive quality systems analyze current material characteristics, equipment status, and environmental conditions to recommend process settings that maximize quality outcomes. The system might suggest modified sewing speeds for particular satin lots, adjusted tension settings for specific elastic combinations, or altered cutting approaches for directional fabrics. These data-driven recommendations have improved our first-pass quality yield by 25% while reducing the experimentation traditionally required to optimize processes for new materials or designs. The system continuously refines its recommendations based on outcome data, creating a self-improving quality environment.

Conclusion

Implementing real-time quality analytics for satin hairbands transforms quality management from a separate inspection function to an integrated manufacturing characteristic. The combination of comprehensive sensing, robust data infrastructure, automated feedback, and predictive capabilities creates a production environment where quality is continuously monitored, maintained, and improved throughout manufacturing. Companies that successfully implement these systems achieve remarkable improvements in product consistency, customer satisfaction, and manufacturing efficiency while reducing costs associated with defects, rework, and returns.

If you're ready to implement real-time quality analytics for your satin hairband production, we invite you to contact our Business Director, Elaine. Our experience in integrating advanced analytics with textile manufacturing can help you achieve similar quality breakthroughs and competitive advantages. Reach her at: elaine@fumaoclothing.com.