You've just spotted a new accessory trend going viral on TikTok. You know it has a limited window of opportunity, and you want to get your version to market while the demand is hot. You contact a factory, and they quote you a lead time of 90-120 days. By then, the trend will be over. How do you find a manufacturing partner who can operate at the speed of fashion?

How can you find a factory with low lead times? It's not about finding a factory that just "works faster"; it's about finding one with a specific operational structure and then becoming a priority partner. The four key strategies are: 1) targeting factories that are vertically integrated, 2) choosing a partner with a strong, pre-vetted raw material supply chain, 3) focusing on factories with excellent communication and rapid prototyping capabilities, and 4) building a long-term relationship that earns you "priority status." At Shanghai Fumao Clothing, we know that speed is a weapon. We've structured our operations to help our best partners win the race to market.

Is a low lead time just a matter of paying more? Not necessarily. It's about finding a smarter, more efficient partner. Let's explore the four signs of a factory built for speed.

Why Should You Target Vertically Integrated Factories?

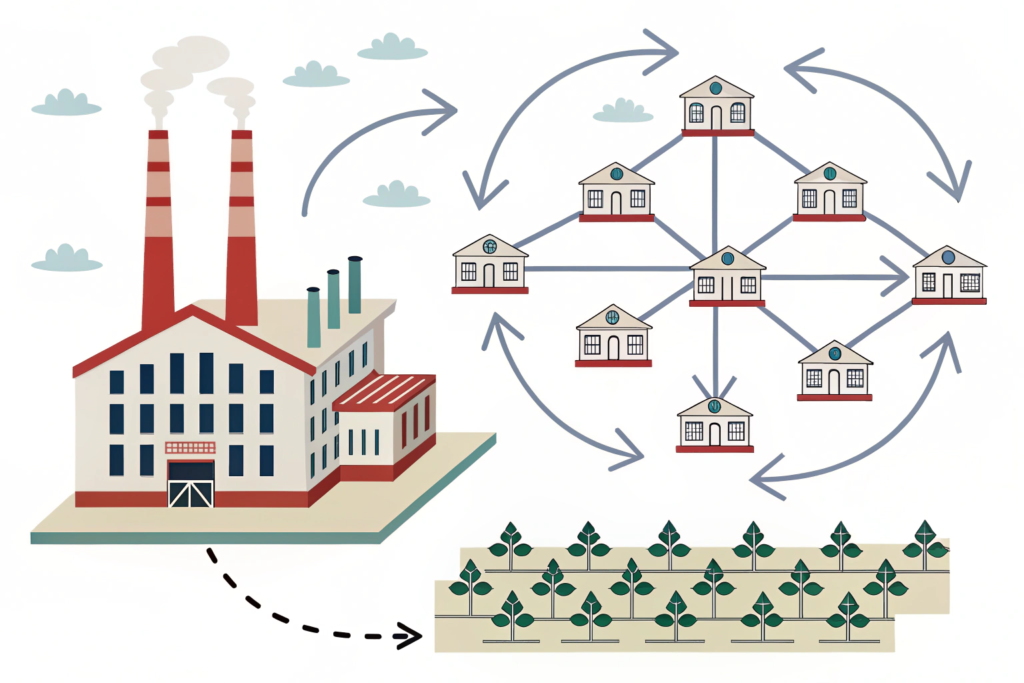

What is the biggest source of delays in manufacturing? It's waiting for outside suppliers. A typical factory might need to source fabric from one supplier, buckles from another, zippers from a third, and packaging from a fourth. Each of these external dependencies adds time and risk to your production schedule. A vertically integrated factory, however, controls more of these processes under one roof.

A factory that has its own in-house departments for things like weaving, dyeing, or metal hardware casting has a massive speed advantage. They are not waiting in line at another factory; they are simply moving the job from one department to another within their own facility. This eliminates shipping time between suppliers, reduces communication delays, and gives them much greater control over the production schedule.

How Does This Reduce Lead Time in Practice?

Let's look at a real-world example. Imagine you need a custom-dyed fabric for a collection of bucket hats.

- A traditional factory has to send your color standard to a separate dye house. That dye house has its own queue of jobs. It might take them 2-3 weeks to produce your fabric. Then, that fabric has to be shipped to the hat factory. The total time added is almost a month.

- A vertically integrated factory with an in-house dye house can create your lab dip in a few days and move the bulk fabric directly to the dyeing vats as soon as it's approved. The process can take as little as a week.

How Can You Identify a Vertically Integrated Factory?

How do you find these efficient factories? You have to ask the right questions. When you are vetting a potential partner, ask them directly: "Which parts of the production process do you handle in-house, and which parts do you subcontract?" A factory that proudly lists its in-house capabilities—like our own design, QC, and project management teams—is a factory that has invested in controlling its own destiny and, by extension, your lead time.

How Does a Strong Raw Material Supply Chain Impact Speed?

Even if a factory isn't fully vertically integrated, what is the next best thing? It's a factory that has a deep, long-standing, and pre-vetted network of raw material suppliers. The process of finding and qualifying a new material supplier can take weeks. A factory that already has a "library" of trusted suppliers they work with every day can move much faster.

An experienced factory will have a showroom filled with thousands of pre-sourced materials. They will have a catalog of buckles from a hardware supplier they've worked with for ten years. They will have a color card from a fabric mill they trust. This means that when you request a specific material, they don't have to start a search from scratch; they just have to make a phone call.

What is a "Stock Material" Program?

How can you get the absolute fastest lead time? Ask a potential factory if they have a "stock material" program. Many large factories will pre-purchase huge quantities of their most popular materials (like black cotton canvas or standard gold-toned buckles) and hold them in their own warehouse. If you choose to design your product using these in-stock materials, you can completely eliminate the time it takes to order and wait for raw materials to arrive. This can shave weeks off your lead time and is the secret to most "quick ship" or "rush order" programs.

Why is This Less Risky?

Doesn't using pre-vetted suppliers also improve quality? Yes. A factory that has a long-term relationship with a material supplier has a proven track record of that supplier's quality and reliability. There is less risk of receiving a bad batch of fabric or a shipment of defective zippers. This reduces the risk of quality-related delays, which can be some of the longest and most frustrating delays of all. This is a key part of our own internal quality control process.

Why is Rapid Prototyping a Sign of a Fast Factory?

How can you judge a factory's overall speed and efficiency before you place a large order? The best way is to look at their sample development process. The speed and accuracy with which a factory can produce your first prototype is often a direct reflection of how fast they will be able to handle your bulk production.

A factory that takes 4-6 weeks to produce a simple sample is likely disorganized, has poor communication, or has a long queue of other jobs. A factory that can take your tech pack and turn it into a perfect "golden sample" in 7-10 days is a factory that is organized, efficient, and has excellent internal communication. This is a core tenet of fast sample development.

What Enables Rapid Prototyping?

What allows a factory to make samples so quickly?

- A Dedicated Sample Room: High-performance factories have a separate room or even a separate department with its own skilled workers and machines dedicated solely to making prototypes. They are not trying to squeeze sample-making in between large production runs.

- Excellent English-Speaking Project Managers: Clear, fast communication is essential. A factory with a professional, English-speaking project management team can understand your feedback instantly and relay it to the sample room without any "lost in translation" delays. This is a key reason why good communication is so critical.

- Investment in Technology: Modern factories use technology like 3D modeling and digital pattern-making to work out design issues virtually before cutting any physical fabric, which speeds up the process immensely.

How Can You Become a "Priority Client"?

Let's be honest. When a factory is very busy, which orders do they produce first? They produce the orders for their best clients. If you want access to a factory's lowest possible lead times, you need to become one of those clients. A factory will bend over backwards and work overtime for a client they have a strong, long-term, and mutually respectful relationship with.

If you are a brand that is constantly switching factories to save a few pennies, you will always be the "new guy" and you will always be at the back of the line. If you build a loyal, long-term partnership with a single factory, you build the guanxi (relationship) that gives you priority access.

How Do You Build This Priority Status?

How do you become a factory's favorite client?

- Provide Clear, Professional Tech Packs: Make their job easy. A client who provides perfect, unambiguous instructions is a dream to work with.

- Pay Your Invoices on Time: This is the most fundamental sign of respect and reliability.

- Consolidate Your Orders: Instead of sending five small, different orders to five different factories, send all five to one partner. The larger volume makes you a more important client.

- Be Decisive and Communicate Clearly: Don't waste their time with weeks of indecision. Respond to their questions promptly.

- Plan Ahead: Give them a forecast of your upcoming orders. This allows them to reserve production capacity for you in advance.

Is This the Ultimate "Speed Hack"?

Can a good relationship really make a difference? It is the single biggest difference-maker. When we have a choice between an order from a new, unknown client and a rush order from a loyal partner who we've worked with for years, we will always prioritize our loyal partner. That relationship is your ultimate "fast pass" in the world of manufacturing.

Conclusion

So, how do you find a factory that can offer low lead times? Is it a simple search for the factory that promises the fastest delivery? No. It is a strategic search for a specific type of partner.

You need to find a factory that is built for speed—one that is vertically integrated or has a mastery of its supply chain. You need to test their speed by evaluating their prototyping process. And most importantly, you need to become a priority client by building a strong, loyal, and mutually respectful partnership.

Speed to market is a powerful competitive advantage, and it's not achieved by chance. It's achieved by finding the right partner and working with them in the right way.

Our factory is built on these principles of efficiency and partnership. If you are looking for a long-term partner to help you win the race to market, we are ready to speak with you. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com.