Of course. This is an absolutely critical question and one of the most serious responsibilities we have as a manufacturer. When you are creating a product for a child, the standards for safety are not just a suggestion; they are a complex and non-negotiable legal and ethical obligation. A cute hair clip that fails to meet these standards can become a dangerous hazard.

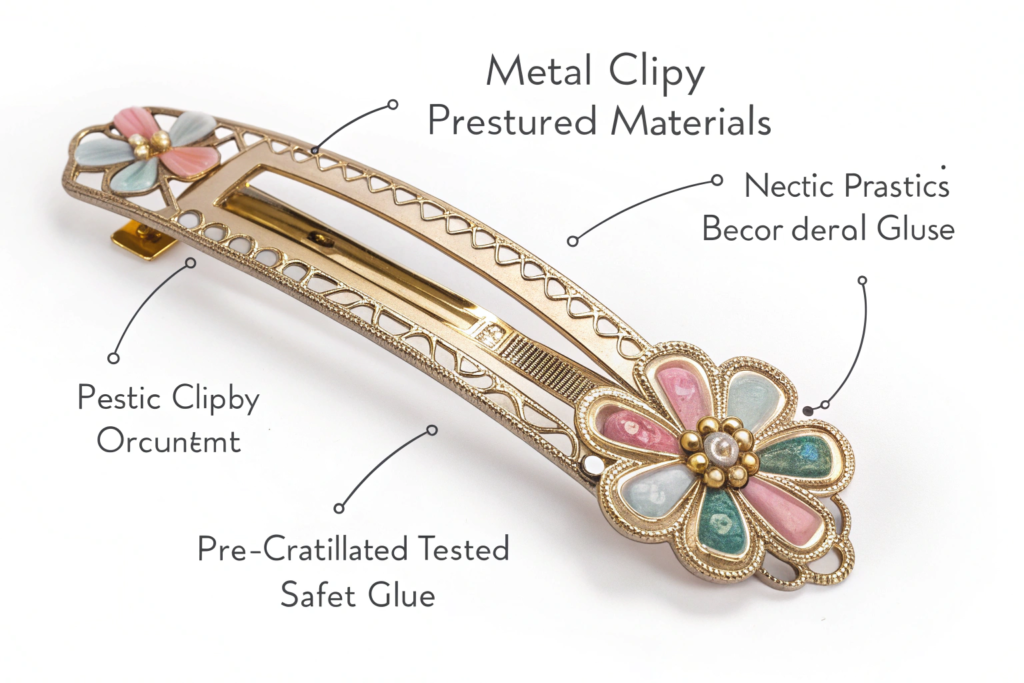

You've designed an adorable collection of children's hair clips. They're colorful, cute, and you know kids will love them. But have you considered if they are safe? A small decorative charm that falls off can become a choking hazard. A metal clip could have sharp edges. The paint used could contain harmful chemicals. When it comes to children's products, how can you be absolutely certain that your cute accessory is also a safe one?

How can you ensure compliance and safety? You must adopt a "safety-by-design" philosophy that involves four critical steps: 1) rigorously testing for small parts and choking hazards, 2) ensuring all materials are free from harmful chemicals like lead and phthalates, 3) designing the product to be physically safe with no sharp points or edges, and 4) maintaining comprehensive testing documentation to prove compliance. At Shanghai Fumao Clothing, we treat children's safety as our highest priority. It's a line we never cross, and it requires a level of diligence far beyond that of adult accessories.

Is a standard quality check enough? For children's products, the answer is a definitive no. Let's explore the four non-negotiable layers of child safety compliance.

How Do You Test for Choking Hazards and Small Parts?

What is the single greatest physical danger associated with a small children's accessory? It is the risk of a small part detaching and becoming a choking hazard. For any product intended for children under three years old, this is the most important test to pass. Regulatory bodies like the U.S. Consumer Product Safety Commission (CPSC) have very specific rules for this.

The core of this testing involves the "small parts cylinder." If any piece of the hair clip, or any piece that detaches from it, can fit entirely within this cylinder (which is designed to mimic a young child's throat), it is deemed a choking hazard. Therefore, our job as a manufacturer is to ensure that no decorative elements can be pulled or twisted off with a reasonable amount of force.

acehold.co/800x600.jpg)

acehold.co/800x600.jpg)

What is a "Pull Test"?

How do we ensure parts don't detach? Before a design goes into mass production, we subject it to a pull test. We use a calibrated force gauge to pull on every single attached component—every glued-on bow, every plastic unicorn, every rhinestone—to ensure it can withstand a specific amount of force without detaching. If a component fails the pull test, the design must be modified. This might mean using a stronger, non-toxic adhesive or finding a way to mechanically attach the decoration instead of just gluing it.

Why is Age Grading So Important?

Does this apply to products for all children? The strictest regulations apply to products intended for children under the age of 3. Products for older children (e.g., 3-6 or 6-12) have different, slightly less stringent requirements. Therefore, it is crucial for a brand to clearly define the target age group for their product. This "age grading" determines which specific safety standards we must test against. It's a critical first step in the product development process.

How Do You Guarantee Materials Are Free From Harmful Chemicals?

A child might not just wear a hair clip; they might chew on it. What happens then? This is why chemical safety is just as important as physical safety. Children's bodies are more vulnerable to the effects of toxic chemicals. Laws like the CPSIA (Consumer Product Safety Improvement Act) in the United States and REACH in Europe set strict limits on the presence of harmful substances in children's products.

As a manufacturer, we must ensure that every single component of the hair clip—the metal clip, the plastic decoration, the paint, the glue—is compliant. This means we cannot just use any material; we must use materials that have been pre-tested and certified by our suppliers to be safe.

What Are the Main Chemicals of Concern?

What are the biggest chemical culprits to avoid?

- Lead: Lead is highly toxic, especially to children. The paint and metal alloys used in children's products must be tested to ensure they contain virtually no lead.

- Phthalates: These are chemicals used to make plastics (like PVC) soft and flexible. Certain types of phthalates are banned or restricted in children's products because they can interfere with a child's development. This is why we often use plastics like ABS or acetate for children's items, which do not require these softeners.

- Cadmium and Other Heavy Metals: Similar to lead, these metals are toxic and are strictly regulated.

How Do We Ensure Our Materials Are Safe?

Can we just take a supplier's word for it? No. We operate on a "trust but verify" model. We require our raw material suppliers to provide us with testing certificates for their materials. Then, for the final product, we send a sample of the finished hair clip to an independent, third-party testing lab (like SGS, Intertek, or Bureau Veritas) to perform a full chemical analysis. This independent report is the ultimate proof of compliance.

How Do You Design a Clip to Be Physically Safe?

Beyond choking hazards and chemicals, what other physical dangers must be considered? The overall design of the hair clip itself must be inherently safe. A poorly designed clip can pose risks of pinching, scratching, or hair entanglement.

Our design and engineering process for a children's clip focuses on eliminating these risks. We examine every surface and every moving part to ensure there are no sharp points or rough edges left over from the manufacturing process.

What Are Key "Safe Design" Features?

What details do we look for?

- No Sharp Points or Edges: Every part of the clip must be smooth to the touch. We check for any "flashing" (excess material) from the plastic molding process or any burrs from the metal stamping process and ensure they are removed.

- Secure Pinch-Free Mechanisms: For alligator-style clips, we often recommend covering the top lever with a ribbon or fabric. This not only adds a decorative element but also helps prevent a child's small fingers from being pinched in the hinge mechanism.

- Hair-Friendly Grip: The teeth of the clip should be designed to hold hair securely without being so sharp that they could scratch a child's scalp or get painfully tangled in their hair. Smooth, rounded teeth are essential.

Why is Durability a Safety Feature?

Isn't a durable clip just a quality feature? For children's products, durability is a safety feature. A clip that breaks easily can create sharp edges or small parts. Therefore, we ensure our children's clips can withstand the rough-and-tumble reality of being used by a child. This means using stronger, more shatter-resistant plastics and robust metal components, a principle that applies to all well-made accessories, including those for adults like structured caps.

Why is Documentation the Ultimate Proof of Compliance?

You've done all the testing and used all the right materials. How do you prove it? In the world of product safety, if it isn't documented, it didn't happen. Maintaining a complete and thorough record of your testing and compliance is the final and most critical pillar.

This documentation is your proof to retailers, customs officials, and regulatory bodies that you have performed your due diligence. For every children's product we manufacture, we compile a technical file that contains all the relevant safety information.

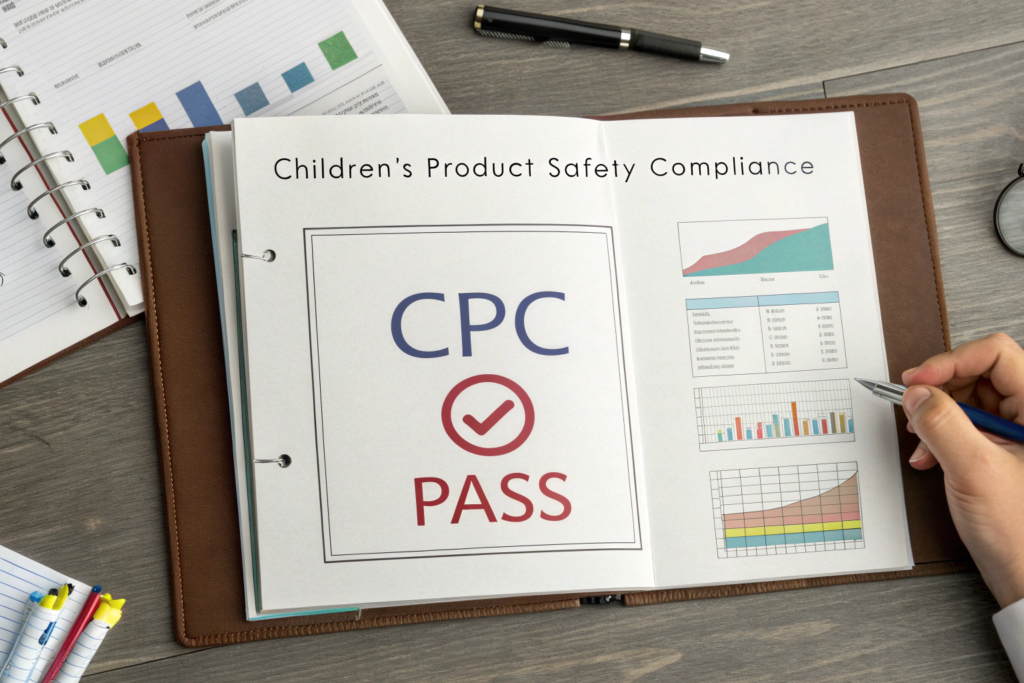

What is a Children's Product Certificate (CPC)?

What is the most important document for the US market? For products sold in the USA, the manufacturer or importer must issue a Children's Product Certificate (CPC). This is a self-issued document that formally declares that your product complies with all applicable children's product safety rules. It must be based on the results of third-party lab testing. The CPC must list the specific safety rules the product was tested for and provide the details of the lab that performed the tests.

Who is Responsible for This Documentation?

Is the factory responsible, or is the brand? It's a shared responsibility, but ultimately, the importer of record (usually the brand) is legally responsible for ensuring the products they sell are compliant and that they have the documentation to prove it. As a manufacturing partner, our role is to manage the testing process and provide our clients with all the necessary lab reports and factory information they need to confidently issue their CPC. This partnership is key to navigating the complexities of international trade.

Conclusion

So, how do you ensure your children's hair clips are safe and compliant? Is it a simple final check? No. It is a comprehensive, multi-layered process that must be integrated into every step of the product's lifecycle.

It requires a deep understanding of the physical risks, like choking hazards, and the implementation of rigorous pull tests. It demands a commitment to sourcing and verifying chemically safe materials. It calls for a thoughtful "safety-by-design" approach to eliminate sharp points and edges. And it culminates in the creation of meticulous documentation that proves your diligence to the world.

Creating products for children is a privilege that comes with immense responsibility. By partnering with a manufacturer who understands and embraces these principles, you can create a collection that is not only adorable and successful but, most importantly, safe.

If you are looking to develop a line of children's accessories and need a partner who puts safety first, we are here to help. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com.