You have a perfect vision for a new bag in your mind. You can see every detail, every pocket, every stitch. But how do you communicate that complex vision to a factory thousands of miles away so that they can create it exactly as you imagined? A simple sketch or a collection of inspiration photos is not enough. You need a technical drawing, also known as a tech pack. This document is the official blueprint for your product. It is the single most critical communication tool in the entire manufacturing process.

How can you create an effective technical drawing? A professional tech pack must be a comprehensive visual and written guide. It must include four essential components: 1) clear, flat, multi-view drawings with precise dimensions, 2) a detailed Bill of Materials (BOM) that specifies every single component, 3) specific construction and stitching callouts that explain how the bag is assembled, and 4) a comprehensive colorway specification sheet. At Shanghai Fumao Clothing, when we receive a detailed tech pack like this, we know we are working with a professional, and we can move into sampling with speed and confidence.

Do you need to be an expert CAD artist? No. But you do need to be detailed and precise. Let's break down the four essential parts of a great bag tech pack.

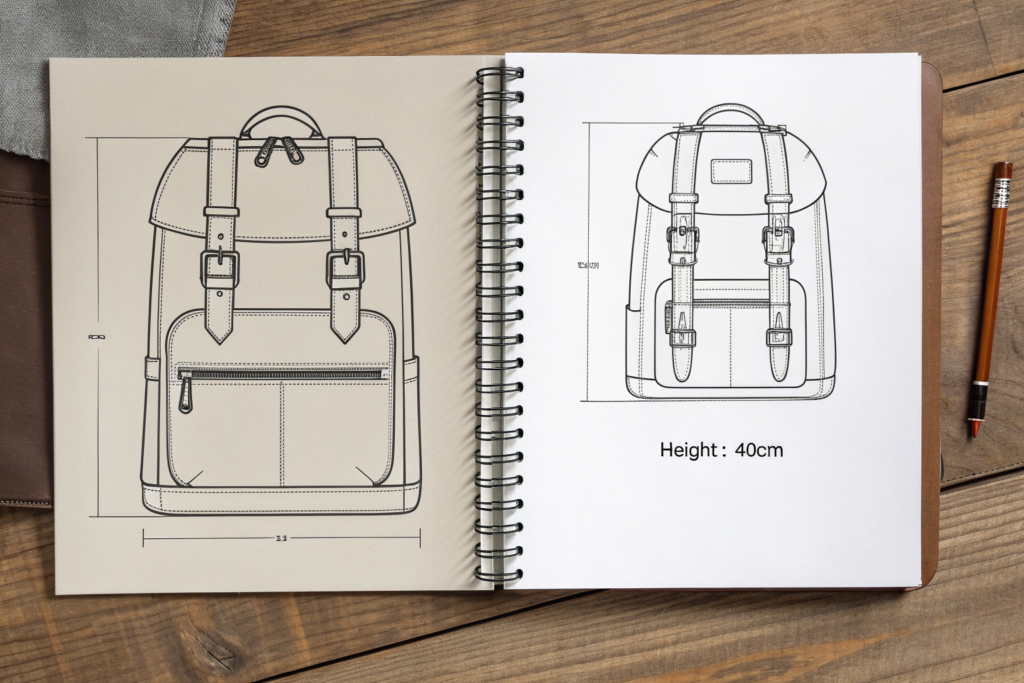

What Are Multi-View Drawings and Why Are They Crucial?

What is the foundation of any tech pack? It's the drawings themselves. You need to provide a series of clear, flat, two-dimensional drawings of your bag from multiple angles. Think of it like an architectural blueprint. These are not artistic, three-dimensional fashion sketches; they are clean, technical line drawings.

At a minimum, you must include:

- A Front View: Showing the bag exactly as seen from the front.

- A Back View: Showing the back of the bag.

- A Side View (Profile): Showing the bag's depth and shape from the side.

- A Top View: Looking down into the bag, showing the main opening and any top details.

- An Interior View: Showing the layout of the pockets and lining inside.

On these drawings, you must add clear dimension lines indicating the exact measurements (in centimeters or inches) for the bag's height, width, depth, strap length, strap drop, and the placement of key features like pockets.

What Tools Can You Use to Create These Drawings?

Do you need expensive software? Not necessarily.

- Professional Standard: The industry standard is Adobe Illustrator. It allows you to create precise vector line drawings that can be easily edited and scaled.

- Simpler Alternatives: Programs like Canva, or even simple drawing apps on a tablet, can be used to create clean line drawings if you are precise.

- Hand Drawings: A neat, clear, and precise hand drawing on graph paper that is then scanned at high resolution can also work, as long as the measurements are clearly written and the lines are straight. The key is clarity, not the tool itself.

Why Are Flat Drawings Better Than 3D Sketches?

Isn't a 3D sketch more realistic? A 3D sketch is great for marketing, but for production, a flat drawing is better because it allows for precise, unambiguous measurements. It removes all artistic perspective and shows the exact proportions and placements my pattern maker needs to create the physical pattern pieces.

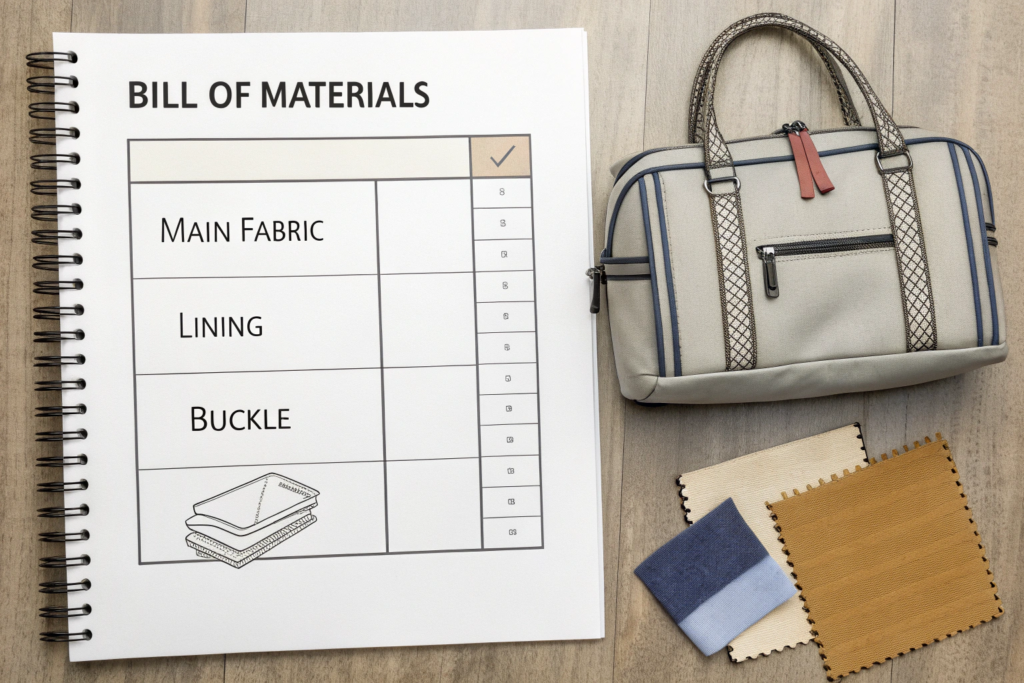

What is a Bill of Materials (BOM) and Why is it So Important?

What is the "ingredient list" for your bag? It's the Bill of Materials, or BOM. This is a detailed, itemized list of every single physical component required to build your bag. This section of the tech pack is critical for my sourcing team to find the exact materials you want and for calculating an accurate price.

Your BOM must be a table that lists each component and provides a detailed description. It should include:

- Main Body Fabric: E.g., "14oz Waxed Cotton Canvas, Color: Olive Green."

- Lining Fabric: E.g., "100% Cotton Twill, Color: Cream."

- Hardware: Every buckle, zipper, snap, and rivet. Specify the material, finish, and size. E.g., "3cm Strap Adjuster, Solid Brass, Antique Brass Finish."

- Zippers: Specify the type (e.g., YKK Vislon ), length, and color.

- Thread: Specify the material and color. E.g., "Polyester Thread, Gutermann."

You should use arrows (callouts) from your technical drawing to point to each component on this list, so it's perfectly clear which item is which.

Why is This Level of Detail Necessary?

Can't I just say "gold buckle"? No. There are hundreds of shades of "gold" (shiny, brushed, antique, rose gold), dozens of materials, and countless styles. If you are not specific, the factory will have to guess, and their guess will likely be wrong. This will lead to sample revisions and delays. Being incredibly specific in the BOM is one of the secrets to fast sample development.

Should You Include Supplier Information?

What if you have a specific supplier in mind? If you have already sourced a specific component, you should include the supplier's name and the item number in the BOM. This is incredibly helpful. For example: "Zipper: YKK, Style #5 Vislon, Color Code: 580."

How Do You Explain the Construction and Stitching Details?

How will the factory know how to put the bag together? You need to provide specific instructions about the construction methods and stitching. This is where you explain the small but critical details that define the bag's quality and durability.

Use callout notes on your drawings to specify details like:

- Stitch Type and Density: E.g., "Use a single needle lockstitch, 8 stitches per inch."

- Seam Construction: E.g., "All main seams to be bound with cotton tape." or "Use a French seam on the lining."

- Reinforcements: E.g., "Add bar-tack reinforcement stitches at all strap connection points." or "Place a rivet at the corner of the pocket for strength."

- Edge Finishing: E.g., "The edge of the leather flap should be painted and burnished."

This is your chance to communicate the "craftsmanship" details. A good factory will know standard construction, but if you want something specific, you must write it down.

Why is This Important for Quoting?

Doesn't this affect the price? Yes, significantly. The cost of a bag is not just in its materials; it's in the labor required to construct it. A bag with simple, raw-edge seams is much faster (and cheaper) to make than a bag with fully bound seams and painted edges. Providing these construction details allows me to give you a much more accurate price quote from the very beginning, avoiding unexpected price increases later.

What if You Don't Know the Technical Terms?

How can you explain it if you're a beginner? Use photos. If you don't know the name for a specific seam type, find a photo of it on another bag and include it in your tech pack with a note saying, "Please make the seam like this." A picture is worth a thousand words, especially when there's a language barrier.

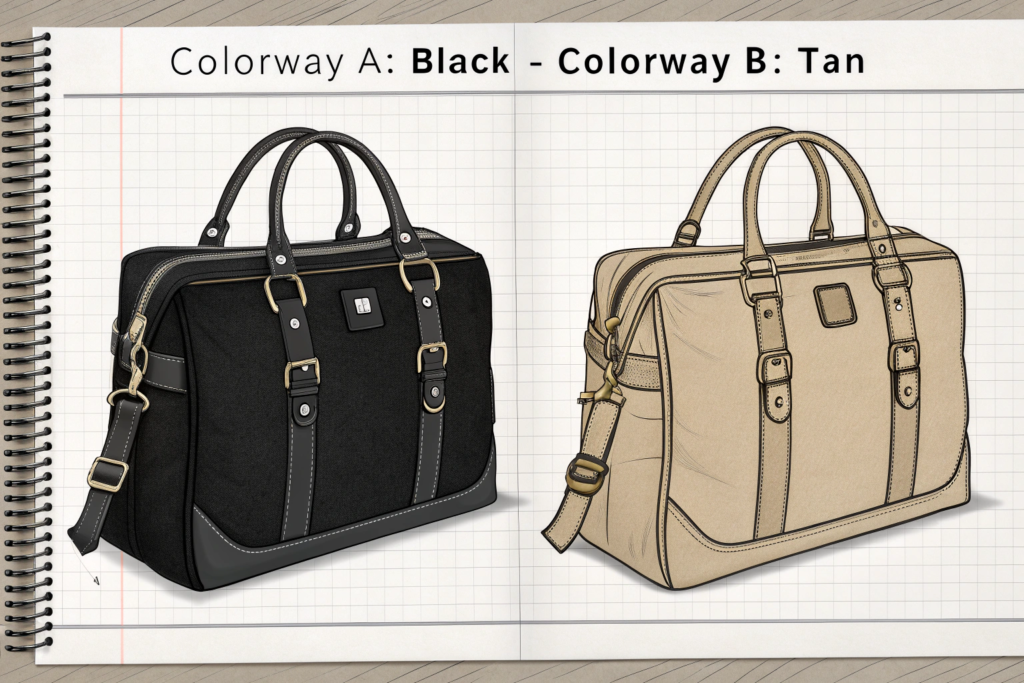

What is a Colorway Sheet and Why Do You Need It?

Your bag might come in three different colors for the season. How do you communicate that? You need a Colorway Specification Sheet. This is a separate page in your tech pack for each color version of your bag.

For each colorway (e.g., "Colorway A: Olive Green"), you need to create a table that specifies the exact color for every single component of the bag. This includes:

- Main Fabric Color (with a Pantone code if possible)

- Lining Fabric Color

- Hardware Finish

- Zipper Tape and Teeth Color

- Thread Color

You can use a copy of your main technical drawing and color it in with the specific colors for that colorway. This visual guide is incredibly helpful for my production team to ensure the right color combinations are used.

Why Can't You Just List the Colors in an Email?

Isn't that easier? An email can get lost. A formal colorway sheet within the official tech pack becomes part of the permanent record for that product. When I send the tech pack to my cutting department, my sewing department, and my hardware supplier, they all have the exact same, correct information. It prevents a disastrous mistake, like the factory producing 1,000 bags with the wrong color lining.

How Do You Specify Colors Accurately?

What is the best way to define a color? The gold standard is the Pantone Matching System (PMS). Providing a Pantone code (e.g., "Pantone 19-4052 Classic Blue") is the most precise way to communicate a color. If you don't have Pantone codes, you can send physical swatches of the colors you want, which my team can then match.

Conclusion

So, how do you create a technical drawing that will get your bag made perfectly? Is it a quick, five-minute sketch? No. It is a detailed, comprehensive, and precise blueprint for your product.

It's about providing clear, multi-view drawings with exact dimensions. It's about creating a complete "ingredient list" in your Bill of Materials. It's about explaining the craftsmanship in your construction and stitching callouts. And it's about defining every color variation with a comprehensive colorway sheet.

Creating a detailed tech pack takes time and effort upfront, but it is the single best investment you can make in your product development process. It will save you weeks of time, hundreds or even thousands of dollars in sample revision costs, and will establish you as a serious, professional partner in the eyes of your manufacturer.

If you have a vision for a new accessory, my team and I are experts at reading these technical drawings and turning them into beautiful, high-quality products. We are ready to build from your blueprint. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com.