As a brand owner, you're constantly thinking about growth. You want to expand your product line, offer more variety to your customers, and capture new market segments. The conventional wisdom might suggest finding a new, specialized factory for each new product category. But what if that's the least efficient path? What if the secret to smart, scalable growth lies not in finding more suppliers, but in building a deeper partnership with the right one?

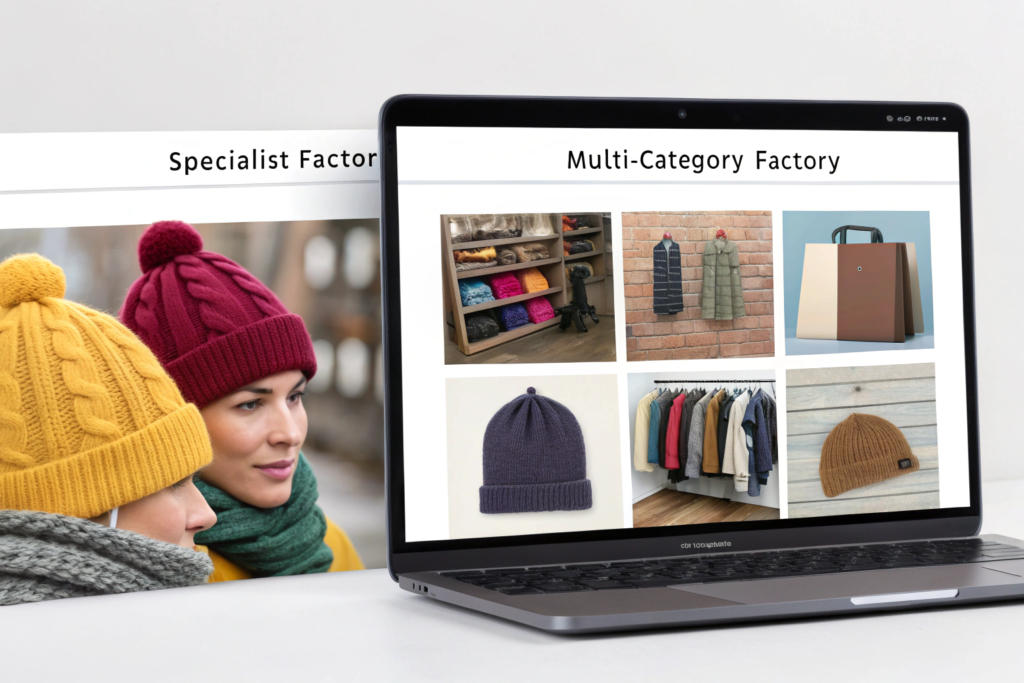

How can you build a diverse product range with a single factory? The key is to shift your mindset from a transactional relationship to a strategic partnership. The four essential strategies are: 1) you must choose a factory with a broad, multi-category production capability from the start, 2) you must leverage their existing material library and supply chain to create new products efficiently, 3) you must collaborate with their design and development team to create "product families" that share common components, and 4) you must use this deep partnership to negotiate better terms and gain priority access to production capacity. At Shanghai Fumao Clothing, our most successful partnerships are with brands who leverage our diverse capabilities to build their entire accessory ecosystem with us.

Is it really possible to make hats and bags in the same place? Yes, if you choose the right partner. Let's explore the four pillars of this powerful growth strategy.

Why Must You Choose a Factory with Broad Capabilities from the Start?

What is the foundational step to this entire strategy? It's choosing the right factory in the first place. If you partner with a small factory that only makes baseball caps, you will never be able to expand into scarves or belts with them. When you are vetting potential long-term partners, you must look beyond your immediate product needs and assess their total manufacturing scope.

You need to find a "generalist specialist"—a factory that has deep expertise across several related product categories. Look for a supplier whose product catalog already showcases a diverse range. Do they show pictures of headwear, neckwear, and leather goods? Do they talk about their experience with both soft goods (like scarves) and hard goods (like buckles and bag hardware)? A factory with a broad, existing capability is the fertile ground upon which you can plant your diverse product seeds.

What Questions Should You Ask to Assess Their Range?

How can you probe their true capabilities?

- "Your website shows you make caps. Have you ever produced bucket hats or beanies?"

- "We are starting with belts, but our five-year plan includes wallets and bags. Do you have experience with those product types?"

- "Can you show me samples of the three most different products you have manufactured?"

- "What product categories are you strongest in, and are there any you prefer not to make?"

Why is This More Efficient Than Finding Multiple Specialists?

Isn't a specialist always better? Not necessarily. While a specialist might be slightly better at one specific thing, managing relationships with five different specialist factories is a logistical nightmare. You have five points of contact, five sets of payment terms, five different QC standards, and five separate shipments to consolidate. The efficiency gains from centralizing your production with one capable, multi-category partner almost always outweigh the marginal benefits of hyper-specialization. It's a core principle of lean supply chain management.

How Can You Leverage Their Existing Material and Component Library?

What is a factory's hidden treasure? It's their material library and their established supply chain. A large, experienced factory has spent years, or even decades, building relationships with dozens of trusted suppliers of fabrics, leathers, zippers, buckles, and threads. When you partner with them, you gain access to this entire network.

This is a massive shortcut for product development. Instead of you having to source a new fabric for a new scarf, you can ask your factory, "What high-quality wools do you already have in your library from your beanie production?" Instead of searching for a buckle supplier for a new belt, you can ask, "Can we use the same high-quality brass buckle from our messenger bag on this new belt design?" This process, known as leveraging common components, is incredibly efficient.

How Does This Reduce Costs and Lead Times?

Why is this faster and cheaper?

- No Sourcing Delays: The factory doesn't have to spend weeks finding and vetting a new material supplier. They can order from their trusted source immediately.

- Lower MOQs: The factory is likely already ordering that material for other clients, which means they can often get you a lower Minimum Order Quantity (MOQ) than if you were starting from scratch.

- Proven Quality: The factory has already tested and approved this material. They know it works, and they know it's good quality. The risk of a material-related quality issue is significantly lower. This is a key part of fast sample development.

How Do You Start This Conversation?

What should you ask your factory? "We are thinking of launching a new tote bag. Before we design it, can you send us a digital catalog or photos of the top 5 most popular and durable canvas fabrics you currently use for other clients? And can you show us the top 3 buckle styles you recommend?" This collaborative approach is the key to unlocking their library.

How Can You Co-Create "Product Families" with Their Development Team?

What is the difference between a collection of random products and a cohesive product range? It's a shared design DNA. A great factory partner has an in-house team of pattern makers, sample developers, and technicians. You should treat this team as an extension of your own design department.

Work with them to create "product families." This means designing different products that share common materials, hardware, and design motifs. For example, you could create a "Heritage Collection" for Fall/Winter that includes:

- A waxed canvas backpack.

- A matching waxed canvas baseball cap.

- A leather belt that uses the same high-quality leather and antique brass hardware as the backpack's straps and buckles.

These products look like they belong together. They tell a cohesive brand story, and from a production standpoint, they are incredibly efficient to make because they draw from the same pool of materials.

How Does This Improve Design and Production?

Why is this a smarter way to design?

- Faster Development: The factory's team already understands your brand aesthetic and quality standards. You don't have to re-teach them for every new product.

- Less Waste: You can make more accurate material orders, and off-cuts from a larger product (like a bag) might be usable for a smaller product (like a keychain or a patch on a hat).

- Stronger Brand Identity: It makes your brand look more professional, established, and thoughtful. Your products look like they were designed as a collection, not as a series of random, disconnected items.

What if You're Not a Designer?

Can the factory help you design? Yes. Many larger factories have development teams that can help you flesh out your ideas. You can come to them with a mood board and a concept, and they can help you turn it into a technical design, suggesting materials and construction methods that will work best.

How Can You Use This Partnership to Gain a Competitive Advantage?

What is the ultimate benefit of consolidating your production with one factory? It's leverage. As your order volume grows and you become a more significant client, your importance to the factory increases dramatically. You are no longer just another small customer; you are a key partner.

This deep relationship gives you leverage that you simply don't have when spreading small orders across multiple factories. You can use this leverage to:

- Negotiate Better Pricing: As your total annual volume increases, you can negotiate for better pricing across your entire product range.

- Secure Production Priority: During busy seasons (like the run-up to the holidays), factories have to decide which clients' orders get produced first. They will always prioritize their largest and most loyal partners. This can be the difference between getting your product on time and missing a key sales window.

- Request More Favorable Payment Terms: A factory is far more likely to offer more flexible payment terms (like a lower initial deposit) to a long-term, high-volume partner they trust.

How Do You Nurture This Relationship?

How do you become a "priority partner"?

- Communicate Clearly and Consistently: Be a good client. Provide clear instructions, approve samples promptly, and pay your invoices on time.

- Share Your Growth Plans: Be transparent with your factory about your future plans. If you tell them you're planning a big holiday marketing push, they can plan their production capacity accordingly.

- Visit in Person: If possible, visiting the factory at least once a year can dramatically strengthen the personal relationship.

Why is This a Win-Win Situation?

Isn't this just better for you? No, it's better for the factory too. It gives them predictable, recurring revenue from a client they understand and trust. It allows them to plan their material purchasing and labor more efficiently. They would much rather have one large, stable client than ten small, unpredictable ones. It is a true symbiotic relationship.

Conclusion

So, how do you build a diverse and successful product range? Do you need a Rolodex full of specialist suppliers? No. The smarter, more scalable, and more profitable path is to build a deep and strategic partnership with a single, highly capable, multi-category factory.

It's about choosing a versatile partner from day one. It's about efficiently leveraging their existing material library to speed up development. It's about collaborating with their experts to create cohesive "product families." And it's about nurturing that relationship to gain the powerful competitive advantages of being a priority partner.

This strategy transforms your manufacturing from a simple cost center into a powerful engine for growth, allowing you to build a bigger, better, and more profitable brand.

If you are looking for a long-term, multi-category partner to help you build your accessory ecosystem, we are ready to be that partner. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com.