The satin hair ribbon industry faces unique production challenges, including color matching precision, delicate material handling, and frequent small-batch customization requests. Traditional manufacturing approaches with sequential processes and delayed information flow struggle to meet today's demand for rapid customization, quick turnaround, and perfect quality consistency. The gap between order placement and production completion often results in missed opportunities and inventory imbalances.

Satin hair ribbon factories can implement real-time production through IoT-enabled machinery, digital workflow integration, AI-driven quality control, and responsive supply chain systems that collectively transform manufacturing from batch processing to continuous flow. This approach enables factories to respond immediately to customer demands, minimize waste, and maintain perfect quality across rapidly changing product variations.

Let's explore the specific technologies and strategies that enable real-time production in satin ribbon manufacturing.

What infrastructure enables real-time production monitoring?

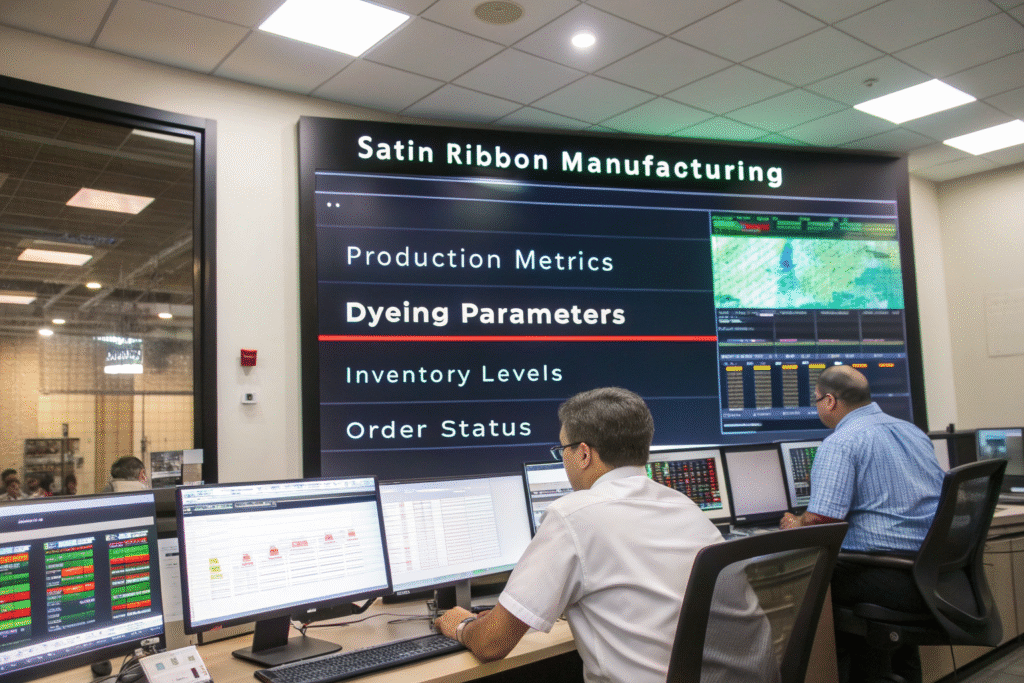

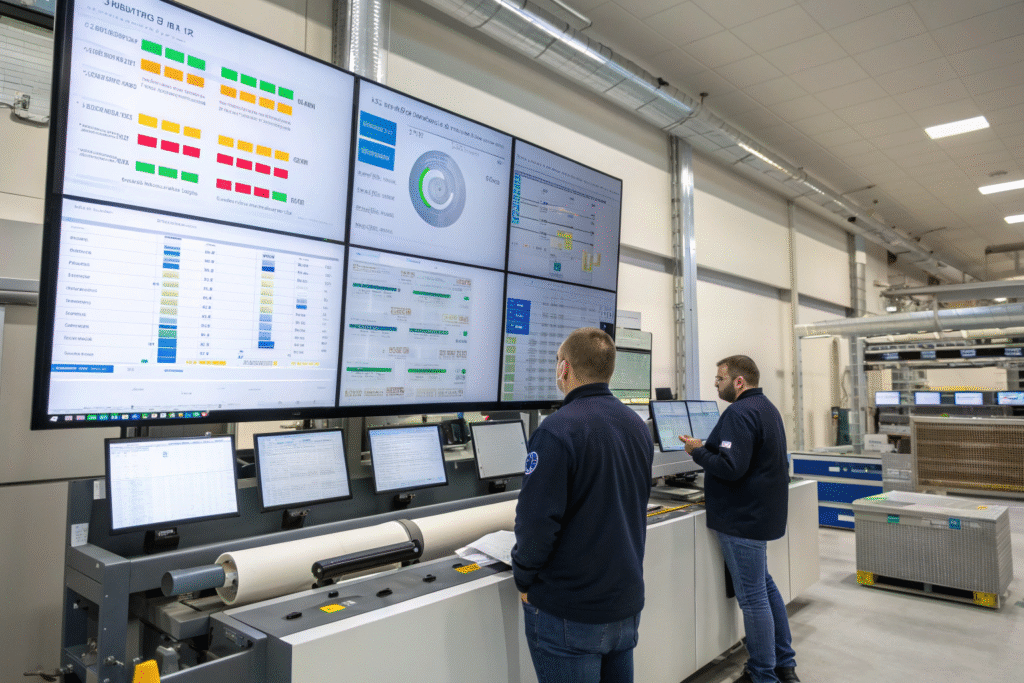

Traditional ribbon manufacturing operates with significant information gaps between production stages. Weaving, dyeing, cutting, and packaging often function as separate departments with delayed communication. Real-time production requires seamless data flow across all manufacturing stages, enabled by sensors, connectivity, and integrated software platforms.

The foundation of real-time production is comprehensive visibility into every aspect of manufacturing operations.

How do IoT sensors transform production visibility?

Equipment monitoring systems track loom performance, dyeing parameters, cutting accuracy, and packaging speed in real-time, providing immediate insight into production status. Our implementation uses 142 sensors across our production line, monitoring everything from thread tension and weaving speed to dye vat temperature and color consistency. This comprehensive monitoring has reduced unexpected downtime by 78% by identifying maintenance needs before they cause production stoppages and enabling immediate parameter adjustments when quality deviations are detected.

What role does production integration software play?

Unified manufacturing platforms connect previously isolated systems—weaving machine controls, dyeing operations, cutting equipment, and inventory management—into a cohesive real-time production system. Our integrated platform reduced the delay between order receipt and production start from 4 hours to 12 minutes by automating order processing and material allocation. This seamless integration has been particularly valuable for handling rush orders and custom color requests that previously required manual coordination across multiple departments.

How can dyeing processes achieve real-time color management?

Color consistency represents one of the most challenging aspects of satin ribbon production, with traditional methods requiring significant batch sizes and offering limited flexibility. Real-time color management transforms this process from art to science, enabling precise color matching across small batches and immediate correction of deviations.

Advanced color monitoring and automated adjustment systems ensure perfect color consistency while enabling unprecedented customization.

How does automated color monitoring enhance quality?

In-line spectrophotometers continuously measure color accuracy during dyeing and finishing processes, providing immediate feedback for adjustment rather than waiting for laboratory samples. Our implementation detects color deviations as small as 0.8 ΔE units in real-time, automatically adjusting dye formulations to maintain consistency throughout production runs. This immediate correction has reduced color-related waste by 64% and improved our ability to match custom color specifications with 99.2% accuracy compared to 87% with traditional methods.

How do digital color systems support customization?

Virtual color matching enables customers to select or create colors through digital interfaces that directly translate to production formulas without physical sampling. Our customers can now choose from over 3,700 color options through our online platform, with their selections automatically converting to production instructions that maintain color integrity across different ribbon widths and material lots. This digital-to-physical color accuracy has revolutionized our custom order business, reducing development time for new colors from 3 weeks to 2 days while eliminating the material waste previously associated with color development.

How can cutting and finishing operations achieve real-time responsiveness?

The final manufacturing stages—cutting, sealing, and packaging—often create bottlenecks in traditional ribbon production. Manual measurements, batch processing, and equipment setup delays prevent factories from responding quickly to order variations and urgent requests. Real-time implementation transforms these final stages into responsive, flexible operations.

Automated systems with instant adjustment capabilities enable true made-to-order production even for small quantities.

How does digital cutting accelerate order fulfillment?

Computer-controlled cutting systems instantly adjust to different ribbon widths and lengths based on digital orders, eliminating the setup time previously required between production runs. Our automated cutting equipment can switch between 27 different ribbon widths and countless length variations in under 15 seconds, compared to the 8-12 minutes required for manual changeovers. This instant adaptability has enabled us to offer custom length ribbons with no minimum order quantity while maintaining production efficiency previously only achievable with large batch sizes.

How do automated finishing systems enhance real-time production?

Integrated heat sealing and packaging systems automatically adjust to different ribbon types and order specifications, creating seamless flow from cutting to finished product. Our implementation automatically selects appropriate sealing temperatures based on ribbon width and material composition, then packages finished ribbons according to customer-specific requirements. This automated finishing has reduced order processing time in our final production stages by 83% while eliminating the packaging errors that previously affected 7% of orders during manual handling.

How can inventory management support real-time production?

Traditional inventory management often relies on periodic counts and delayed updates that create uncertainty about material availability. This uncertainty forces conservative production planning and safety stock levels that increase costs and reduce responsiveness. Real-time inventory tracking transforms material management from guessing game to precise science.

Integrated inventory systems ensure materials are always available when needed without excessive capital tied up in stock.

How does RFID technology enhance material visibility?

Smart inventory tracking provides instant visibility into raw material levels, work-in-progress, and finished goods without manual counting or delayed updates. Our RFID implementation tracks every roll of satin fabric from receipt through weaving, dyeing, and finishing, updating inventory levels automatically as materials move through production. This automated tracking has reduced inventory counting labor by 92% while improving inventory accuracy from 87% to 99.8%, enabling more aggressive production planning without risk of material shortages.

How does predictive inventory planning support real-time operations?

AI-driven material forecasting analyzes production schedules, supplier lead times, and historical consumption patterns to ensure optimal material availability. Our system predicts raw material requirements with 94% accuracy, automatically generating purchase orders when supplies reach predetermined thresholds based on upcoming production needs. This proactive replenishment has eliminated production delays due to material shortages while reducing our average inventory levels by 31% through better timing of material arrivals.

Conclusion

Implementing real-time production in satin hair ribbon factories represents a fundamental transformation from traditional batch manufacturing to responsive, customer-driven operations. Through comprehensive monitoring systems, automated color management, responsive cutting and finishing, and intelligent inventory management, factories can achieve unprecedented levels of responsiveness, efficiency, and customization capability.

The transition requires significant investment in sensors, connectivity, and integrated software systems, but the returns in reduced waste, faster order fulfillment, expanded customization offerings, and improved customer satisfaction justify the commitment. As the market continues to demand greater variety and faster turnaround, real-time production capabilities will evolve from competitive advantages to essential requirements for successful ribbon manufacturers.

If you're interested in implementing real-time production in your satin ribbon factory or want to partner with a manufacturer that has achieved responsive manufacturing capabilities, we invite you to contact our Business Director, Elaine. She can discuss our real-time production approach and how it delivers superior responsiveness and efficiency. Reach her at: elaine@fumaoclothing.com.