Are you tired of receiving accessory shipments that are damaged upon arrival? The problem often lies in inadequate shock absorption. This issue leads to customer dissatisfaction, increased return rates, and ultimately, profit loss. For buyers sourcing from overseas, ensuring product integrity during transit is a constant battle.

The key to solving this problem is to source accessories that are specifically designed with shock-absorbing features and to partner with a manufacturer that has robust packaging and quality control processes. This involves understanding the materials, design elements, and logistical partnerships that collectively protect your goods from the rigors of international shipping. By focusing on these aspects, you can significantly reduce damage rates and ensure your products reach your customers in perfect condition.

Let's explore the critical steps you need to take to secure accessories that can withstand the journey from our factory in China to your warehouse in the US.

What Materials Offer the Best Shock Absorption for Accessories?

When sourcing accessories like hair clips, sunglasses, or delicate hair bands, the material choice is your first line of defense. Not all materials are created equal when it comes to impact resistance. Selecting the right one can mean the difference between a pristine product and a broken one.

The best materials for shock absorption in accessories include flexible polymers, certain types of foam, and silicone-based compounds. These materials are chosen for their ability to absorb and dissipate energy upon impact. For instance, TPR (Thermoplastic Rubber) is excellent for flexible components on hair clips or headbands, as it can bend and bounce back without breaking. Similarly, EVA foam is widely used inside packaging or as a core material for thicker items because of its lightweight and cushioning properties.

Why is TPR a Top Choice for Flexible Components?

Thermoplastic Rubber (TPR) is a popular material for parts that need to flex, such as the hinges on hair clips or the bands on headwear. Its molecular structure allows it to stretch and compress, absorbing shock rather than transferring it to more rigid, breakable parts. At AceAccessory, we often recommend TPR for key stress points because it combines durability with a soft-touch feel, enhancing the user experience. Furthermore, TPR is a cost-effective material, which helps in maintaining a competitive price point without sacrificing quality. It's also easy to color, allowing for vibrant designs that appeal to a broad market. When you work with a manufacturer experienced in injection molding, you can create complex TPR components with consistent quality.

How Can EVA Foam Enhance Product Protection?

Ethylene-Vinyl Acetate (EVA) foam is a closed-cell foam known for its exceptional cushioning. It is often used as a padding material within the product itself or as a key element in the packaging. For example, we can laminate a thin layer of EVA foam inside a fabric-based headband to add structure and shock absorption. Its lightweight nature means it doesn't significantly increase shipping costs, a crucial factor for importers. The versatility of EVA foam also allows it to be die-cut into custom shapes, providing a snug fit for specific products like decorated hair clips or fragile sunglasses within their retail boxes, ensuring they don't move around during transit. Partnering with a supplier that understands custom foam fabrication is essential for maximizing these benefits.

How Does Design Engineering Improve Shock Resistance?

The way an accessory is designed plays a crucial role in its ability to withstand impacts. Good design can reinforce weak points and distribute force away from critical areas. It's not just about the material; it's about how the material is used.

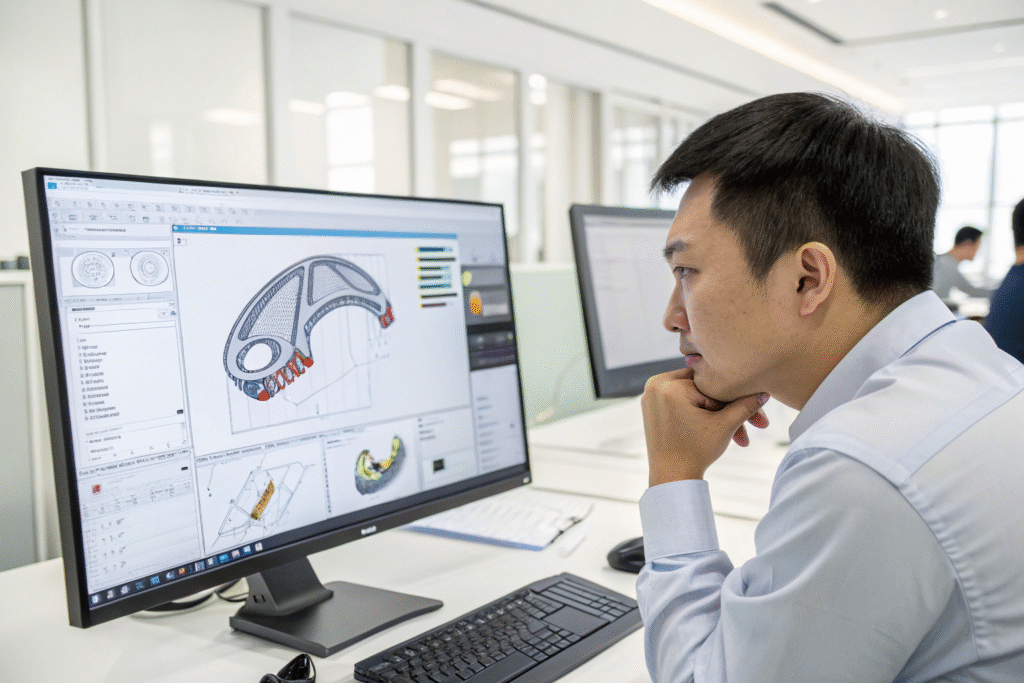

Design engineering for shock resistance involves creating structures that absorb and redirect energy. This can include strategic ribbing, living hinges, and unified designs that reduce the number of fragile parts. A well-engineered design anticipates the stresses of shipping and daily use, building durability into the product from the very first sketch. Our design team at AceAccessory uses CAD software to simulate stress tests before a prototype is even made, saving time and ensuring a higher success rate.

What Role Do Living Hinges Play?

A living hinge is a thin, flexible hinge made from the same material as the two rigid parts it connects, commonly used in plastic hair clip cases or compact mirrors. This design feature is incredibly effective for shock absorption because it allows the product to flex as a single unit rather than breaking at a rigid joint. The hinge bends under pressure, distributing the force along its length. This eliminates the need for separate metal hinges, which can rust, break, or require more complex assembly. For buyers, this means a more reliable product with fewer potential failure points. When sourcing, ask your manufacturer if they have experience designing injection molded living hinges for similar accessories.

How Can a Unibody Design Minimize Damage?

A unibody design means creating a product from a single piece of material, or as few pieces as possible. This approach significantly improves shock resistance because there are fewer glued or snapped-together joints that can come apart under impact. For example, a sunglasses frame molded as a single piece is far more durable than one with arms that screw on. We apply this principle to many of our products, such as one-piece headband forms or seamless metal rings for keychains. This not only enhances durability but also often simplifies the assembly process, leading to faster production times. It is a key aspect of Design for Manufacturability (DFM) that savvy importers should discuss with their suppliers.

What Packaging Solutions Maximize Shipping Safety?

Even the most shock-absorbent accessory can be damaged by poor packaging. The packaging is the final shield that protects your investment during the often-brutal logistics chain. Effective packaging is a system that works in layers.

The best packaging solutions use a combination of primary, secondary, and tertiary layers to cushion, block, and brace the products. Primary packaging is the retail box, which should be sturdy. Secondary packaging involves inner cushioning like foam or corrugated inserts. Tertiary packaging is the master shipping carton. Each layer must be engineered to work together. We ensure our corrugated boxes meet or exceed the required bursting strength standards for international shipping.

Why are Custom Molded Inserts a Game-Changer?

Off-the-shelf packaging often leaves empty space, allowing products to shift and collide during transit. Custom molded inserts, made from foam or pulp, are designed to hold each accessory securely in place. This is especially critical for items with delicate decorations or multiple components. The insert acts as a cradle, absorbing shocks and vibrations from all directions. While there is an upfront tooling cost, it is often offset by the drastic reduction in damaged goods and associated returns. For high-volume orders, this investment is essential. We work with clients to develop these custom solutions, ensuring that even the most fragile items arrive safely. This is a critical part of a reliable fulfillment center process.

How Does Master Carton Configuration Matter?

The way individual product boxes are arranged and secured within the master shipping carton is vital. Proper configuration involves using partitions to prevent boxes from rubbing against each other and ensuring the carton is filled to capacity without being over-packed. We also pay close attention to the stacking strength of the carton to prevent collapse if other boxes are stacked on top. For our clients, we provide a recommended packing layout that optimizes cube utilization and maximizes protection, which is a key value-add for importers concerned about shipping logistics.

How to Verify a Supplier's Capability for Shock-Resistant Products?

You can have the best design and packaging, but if the manufacturer lacks the quality control processes to execute consistently, it's all for nothing. Verifying a supplier's capability is the most critical step in the sourcing journey.

This verification goes beyond a simple website check. It involves assessing their quality management systems, production equipment, and testing protocols. A professional factory will be transparent about its processes and welcome audits. At AceAccessory, we have a dedicated quality control team that operates at every stage of production, from raw material inspection to final pre-shipment checks.

What Quality Certifications Should You Look For?

Certifications are independent validations of a factory's commitment to quality and standardized processes. Key certifications to look for include ISO 9001 for quality management systems. This certification demonstrates that the factory has documented procedures for controlling production, identifying defects, and implementing corrective actions. While not specific to accessories, it shows a foundational level of professionalism. For certain markets, you might also need product-specific certifications like CE marking for Europe or CPC for children's products in the US, which can involve safety and material tests.

What On-Site or Virtual Audits Are Essential?

Nothing replaces seeing the operation for yourself. An on-site audit allows you to check the factory's cleanliness, organization, and machinery. You can observe the production line and speak directly with the quality control managers. If travel isn't possible, a live virtual audit via video call is a effective alternative. Key things to verify include: 1) The presence of a dedicated QC station with proper lighting and measuring tools. 2) How they handle and segregate defective products. 3) Their process for conducting drop tests and compression tests on packaged products. We regularly conduct these tests and are happy to share the results with potential partners to build trust.

Conclusion

Sourcing accessories with reliable shock-absorbing features is a multi-faceted process that requires attention to material science, design engineering, packaging innovation, and rigorous supplier verification. By understanding the properties of materials like TPR and EVA foam, insisting on smart design principles like living hinges and unibody construction, implementing layered packaging solutions with custom inserts, and thoroughly vetting your manufacturer's quality control systems, you can dramatically minimize the risk of shipping damage. This comprehensive approach protects your profit margins and strengthens your brand's reputation for quality.

If you are looking for a reliable partner to produce your next line of durable, high-quality accessories, we invite you to contact us. Our team is ready to provide timely, professional, and reliable service. For a consultation, please reach out to our Business Director Elaine at elaine@fumaoclothing.com. Let's work together to create products that arrive as perfect as they leave our factory.