Lean manufacturing has transformed how accessory brands source their products globally. If you're a brand like Ron in the U.S.—confident, experienced, and focused on quality—working with a lean manufacturing-based factory could be the secret weapon in your sourcing strategy.

Partnering with a lean manufacturing accessories factory means less waste, faster turnaround, and more consistent product quality. For U.S. and European buyers, especially those navigating tight retail schedules, lean operations offer exceptional reliability and competitive advantage.

Instead of juggling delays, wasteful packaging, or inconsistent quality, sourcing from a lean facility ensures optimized production and delivery—ideal for buyers concerned about rising tariffs, shipping costs, and customer satisfaction.

How Does Lean Manufacturing Improve Accessory Production?

What Makes Lean Lines More Efficient?

Lean manufacturing eliminates non-value activities. In accessory production, this might mean organizing tools, reducing fabric waste, or using digital cut plans. By streamlining every step, lean lines are faster and smarter.

Our Zhejiang factory uses the 5S method and just-in-time principles to reduce waiting time. That’s why our clients in the U.S. consistently get accessories like custom belts or knitted hats on time—even during holiday peaks.

How Does Lean Reduce Defects and Reworks?

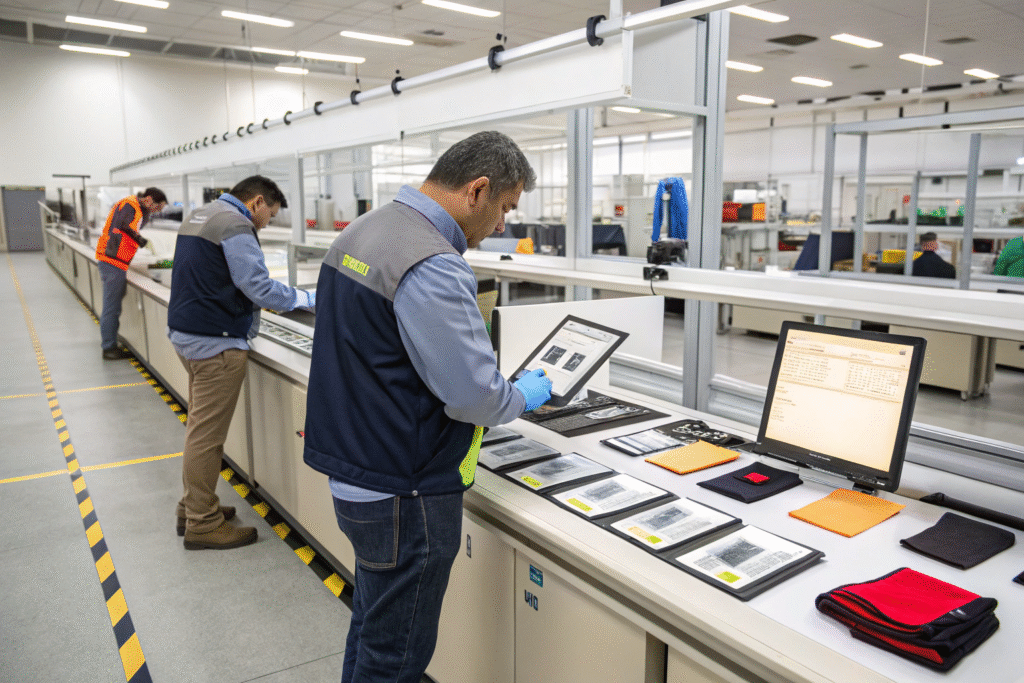

Lean focuses on quality at the source. Instead of fixing errors post-production, we prevent them with checklists, in-line inspection, and poka-yoke tools. For example, our sewing stations have color-coded guides for stitching scarf edges correctly.

This helps brands like Ron’s avoid rework delays or product returns. And it contributes to our impressive 98.7% on-time delivery rate—a fact supported by many in our LinkedIn testimonials.

Is Lean Manufacturing More Cost-Effective?

How Does Lean Save Material Costs?

We apply lean thinking to material handling. For instance, our hairband production uses digital fabric nesting software to reduce offcuts. We reuse leftover trims in budget-friendly accessory lines or donate them to local craft schools.

By cutting waste, we lower material costs. That’s why our hair accessories are not just stylish, but also cost-effective for major U.S. retailers.

Does Lean Impact Labor and Overhead?

Yes. Lean practices boost worker productivity without overtime. Instead of adding labor during peak orders, we flex capacity with takt-time planning. That means our clients pay only for true value-added hours.

Even our lean training system helps reduce onboarding costs—new hires become productive in 2–3 days instead of weeks.

How Does Lean Manufacturing Affect Order Lead Times?

Can Lean Manufacturing Reduce Production Time?

Absolutely. Lean setups allow fast changeovers between different accessory SKUs. When switching from wool gloves to straw hats, we reorganize stations in under 12 minutes using SMED (Single-Minute Exchange of Die).

This gives brands like Ron’s more flexibility in seasonal orders, especially when facing demand surges from U.S. sales events like Black Friday.

How Does Lean Help Meet Tight Shipping Deadlines?

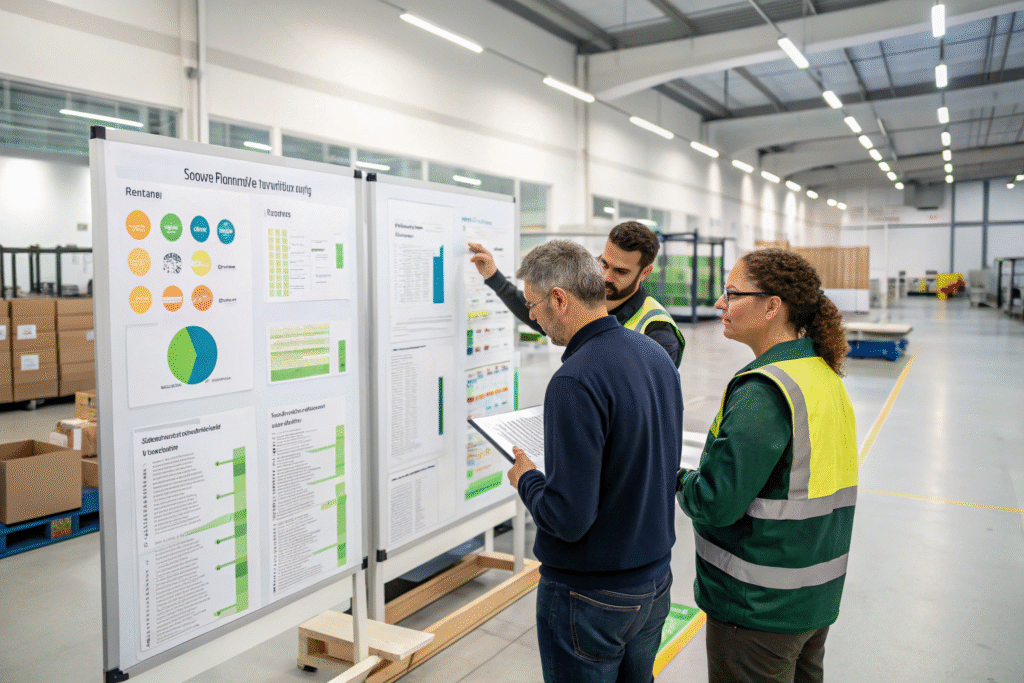

Lean production is predictable. We can sync production with your logistics schedule to reduce warehouse time. Our internal system updates production status every hour, which we share via online dashboards.

We even offer pre-labeled cartons to reduce customs clearance delays—helping reduce overall shipping lead time by 2–3 days per batch.

What Are the Quality Control Benefits of Lean Processes?

Why Is Real-Time Quality Monitoring Important?

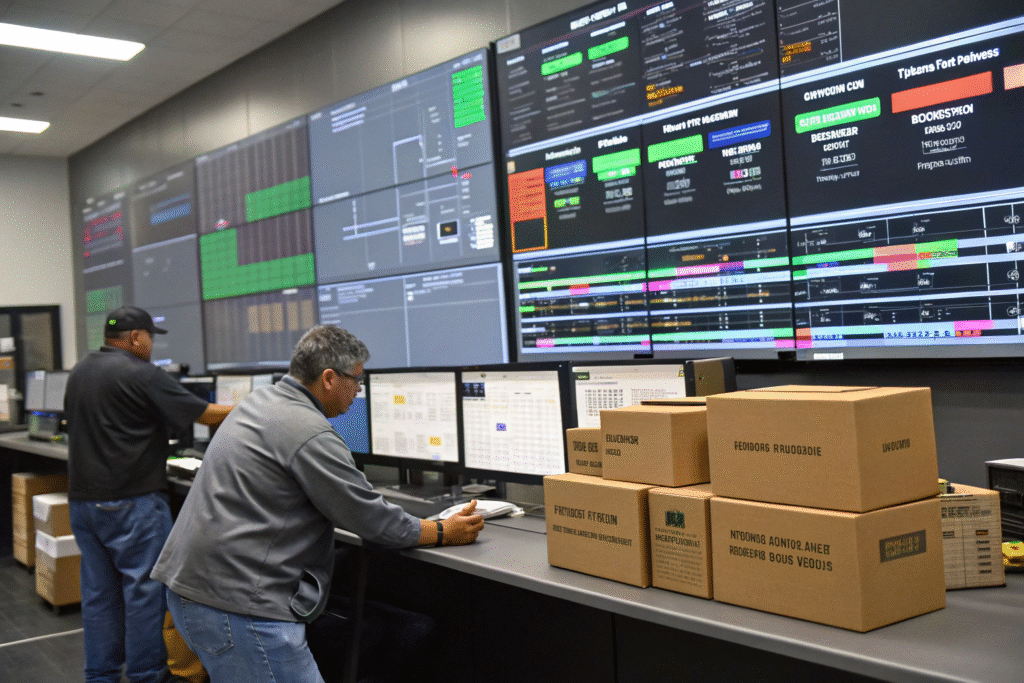

Lean factories do not wait for post-production checks. Every operator is trained to stop the line when something’s wrong. This "Jidoka" principle ensures accessories like buckled belts or printed caps meet specifications instantly.

Our U.S. clients get access to live QC updates via our portal. We even integrate with product lifecycle tools to align product specs, packaging, and compliance checks.

How Does Lean Ensure Consistent Results?

We use visual guides, SOPs, and digital logs at each workstation. Whether it’s embroidery alignment for scarves or logo placement on caps, the setup ensures consistency across 10,000+ pieces.

Our lean-inspired Kaizen events drive monthly improvements, helping us maintain less than 1.2% defect rate across categories.

Conclusion

Choosing a lean manufacturing-based accessories factory is more than a cost-saving decision—it’s a strategic move. From minimizing waste to maximizing speed and consistency, lean operations give you a long-term competitive edge.

If you’re sourcing hats, belts, scarves, or hair accessories and want fast, clean, and reliable service—our Zhejiang-based team at AceAccessory is ready. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to explore how we can help you streamline your sourcing.