Vegan leather belts are rising in demand, but finding the right source is not always easy. While buyers seek cruelty-free, sustainable options, the market is filled with greenwashing, inconsistent materials, and MOQ limitations. Especially for fashion brands focused on ethical sourcing, the belt category presents a unique challenge.

Sourcing vegan leather belts comes with challenges in raw material consistency, MOQ policies, certification credibility, and product durability—but solutions exist in supplier verification, new materials, and smart negotiation strategies.

At AceAccessory, we’ve helped many U.S. and European clients transition from traditional leather to plant-based or PU belts. I’ll walk you through the top pain points and how we’ve solved them for accessory brands big and small.

Why Is Vegan Leather Quality So Inconsistent?

Not all vegan leather is created equal—and the inconsistency often ruins the final product.

Vegan leather varies widely in softness, flexibility, strength, and appearance depending on source, process, and price. This affects belt stitching, drape, and long-term use.

How Do Material Types Affect Quality?

Common types include PU (polyurethane), PVC, Pinatex (pineapple fiber), and Desserto (cactus leather). While PU is affordable and uniform, it lacks sustainability. On the other hand, plant-based leathers offer strong eco-brand appeal but often have coating issues and batch variation.

We once worked with a Danish buyer who used mushroom leather—only to find the material cracked under dry European winters. We now conduct climate wear testing on all belt materials using procedures based on ISO 17233.

What’s the Solution for Maintaining Consistent Quality?

Start with approved lab testing (like SGS or Intertek), even at prototype stage. Ask your supplier to provide material batch tracking numbers, and always request multiple swatch cards. At AceAccessory, we use a standard “Tension + Texture” testing protocol to evaluate new materials before applying them to belts.

We also photograph each batch’s embossing and gloss level under controlled lighting for repeat accuracy.

How Do MOQs Create Barriers for Small Buyers?

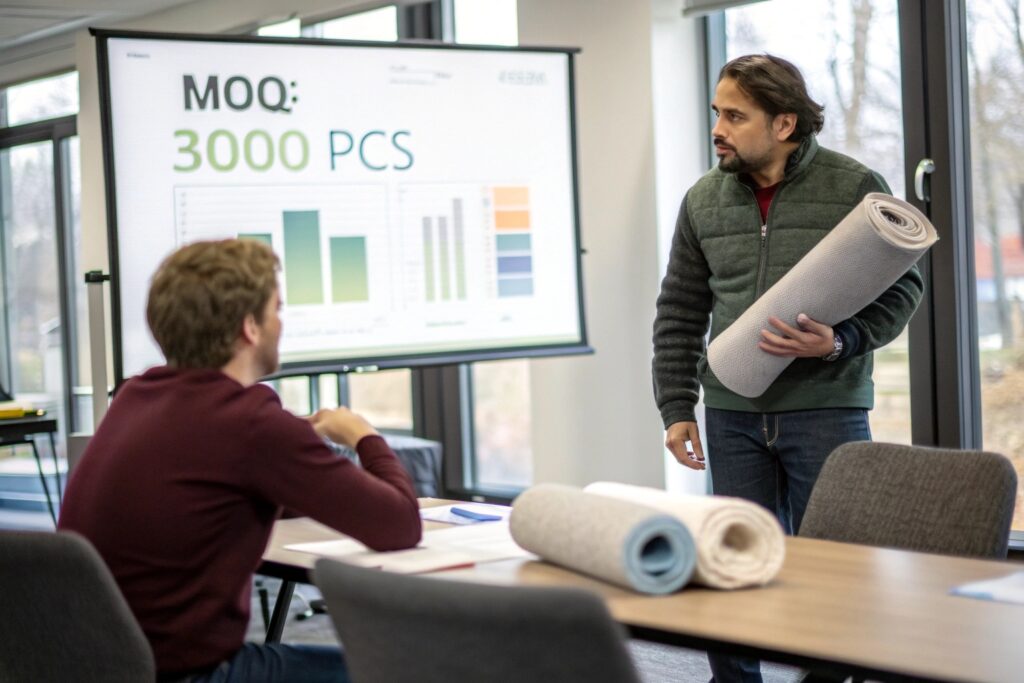

Many suppliers of vegan leather belts require large MOQs due to expensive raw materials and unstable yield.

High minimum order quantities (MOQs) are a major hurdle for small brands that want to test vegan leather belts without committing to thousands of units.

Why Are MOQs So High for Plant-Based Leathers?

The production of pineapple, cactus, or mushroom-based leather often happens in limited supply chains. The cost per meter is higher, and factories hesitate to cut partial rolls. As a result, typical MOQs can range from 1,500 to 3,000 pcs per belt style, especially when using natural leather alternatives.

Suppliers also face yield variability—one cactus pad might produce enough material for 15 belts or 50, depending on process optimization. This limits their flexibility.

What Are Some Practical MOQ Solutions?

At AceAccessory, we solve this in three ways:

- PU Hybrid Strategy – We blend PU with a percentage of plant-based content (e.g. 20% cactus pulp) for lower-MOQ runs.

- Roll Sharing – We pool material orders across multiple clients for the same leather color or texture.

- Style Consolidation – If a client orders multiple SKUs with the same strap base, we count them toward one MOQ.

For example, a startup client in Berlin was able to produce 5 belt styles using just 600 meters of cactus-blended PU, cut across 1,200 pcs total.

Can Vegan Belts Really Meet Durability and Performance Needs?

Customers may love the story—but they hate when a belt peels, cracks, or stretches too easily.

One of the most common problems with vegan leather belts is durability, especially around the buckle area where stress concentration is highest.

What Are the Main Durability Concerns?

Unlike real leather, many synthetic alternatives stretch and degrade faster. PU and PVC belts can crack at fold points, and plant-based leathers may lose finish over time. A 2023 Consumer Reports study found that some mushroom leather belts broke after just 8 weeks of use.

That’s why we insist on testing flex resistance, abrasion, and UV exposure during sampling. One of our tests uses a buckle clamping robot that applies 10,000 flexes to simulate real-world use.

How Do We Improve Belt Longevity?

We reinforce vegan leather belts with nylon or cotton canvas interlining to avoid stretch and tear. We also apply hot seal coatings that increase scratch resistance. The use of edge-painted binding has proven to reduce cracking around stitching.

For clients that ship to dry climates like Colorado or Alberta, we offer silicone-laced top coats to prevent drying and brittleness.

How Do Buyers Avoid Greenwashing and Verify Sustainability?

Claiming to sell “vegan leather” is easy. Proving it is the hard part.

Greenwashing is a major concern in the accessory world—many suppliers use vague “eco” terms without any proof of material origin, production method, or worker ethics.

What Certifications Matter in Vegan Leather Sourcing?

Real compliance starts with:

- GRS (Global Recycled Standard) for blended content

- PETA-Approved Vegan for cruelty-free processes

- FSC for packaging and natural fiber backing

- REACH compliance to confirm no harmful chemicals

We provide documentation and factory audit reports for every eco-leather order. Clients often ask us to include these when listing belts on platforms like Nordstrom Sustainable Hub.

How Can Buyers Protect Themselves from Greenwashing?

Ask suppliers for COA (Certificate of Analysis) and the material supplier's contact. Perform random traceability audits, or work with third-party agencies like Control Union or Ecovadis.

We also share video footage of our belt production and link traceable QR codes to packaging so end-customers can verify the supply chain.

Conclusion

Sourcing vegan leather belts is not without hurdles—from inconsistent materials and high MOQs to durability doubts and certification confusion. But with the right partners, these challenges can be solved. At AceAccessory, we help brands develop belt lines that look good, last long, and tell a true sustainability story. Whether you’re launching a new eco-line or transitioning away from animal leather, we’ve got the systems, materials, and ethics to support you—belt by belt.