You have a groundbreaking design for a multi-compartment, multi-material bag. The vision is clear in your mind, but communicating every intricate detail to a factory feels daunting. An incomplete or vague tech pack is the single biggest reason complex designs fail in production, leading to costly errors, endless sample revisions, and products that don't match your vision.

Creating a flawless tech pack for a complex bag is about building a comprehensive, visual, and unambiguous instruction manual for your manufacturer. It must act as the single source of truth, detailing every component, measurement, material, and construction step. At Shanghai Fumao Clothing**, we develop and receive hundreds of tech packs yearly, and the successful ones share a common trait: they leave no room for interpretation. A great tech pack transforms your creative idea into an engineered, manufacturable product.

This guide will walk you through the essential components and best practices to create a professional tech pack that empowers your factory to execute your complex design perfectly.

What Are the Foundational Elements of a Bag Tech Pack?

Before diving into complex details, you must establish a clear, professional foundation. A tech pack is more than a sketch; it's a formal document that sets the tone for the entire project. Missing foundational elements force the factory to make assumptions, which is where mistakes are born.

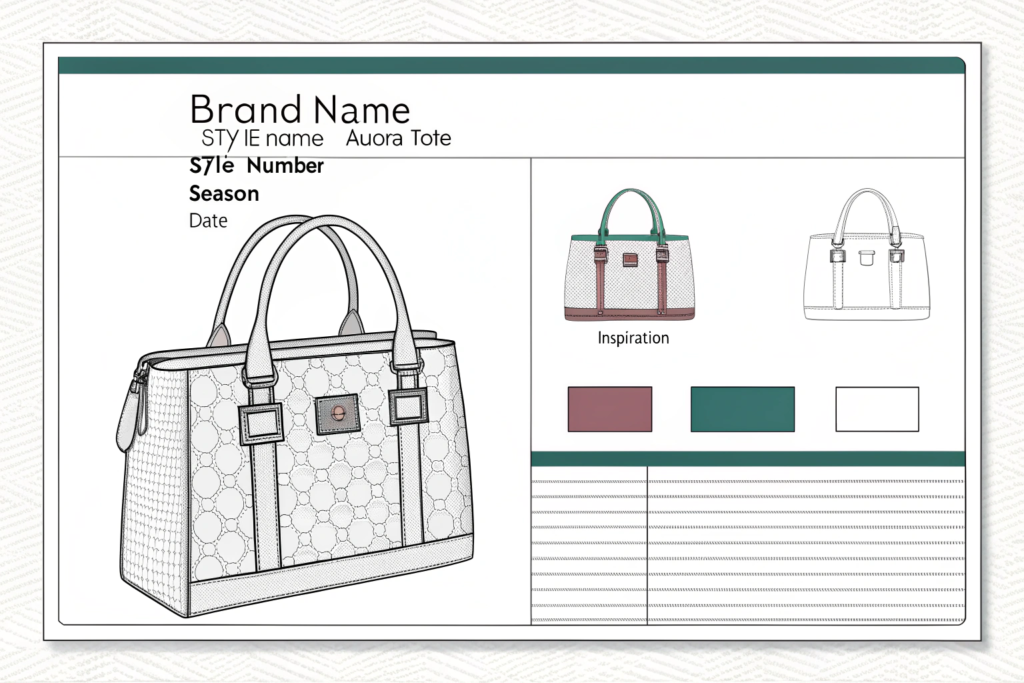

Your tech pack must open with clear identification, inspiration, and a comprehensive flat sketch. These elements provide context and an overarching visual reference that all subsequent details will support. Think of this section as the cover page and executive summary of your product.

Providing a clear foundation is the first step in enabling a manufacturer's design and development capability to support your vision effectively.

What Should Be on the Title Page and Flat Sketch?

Title Page Essentials:

- Brand/Company Name

- Style Name & Number: Use a logical numbering system (e.g., AT-2026-01 for Aurora Tote).

- Season & Intended Launch Date

- Date of Tech Pack Creation/Revision

- Target FOB Price Range (Optional but helpful)

The Flat Technical Sketch:

This is a non-negotiable, 2D line drawing showing the bag from all necessary angles: front, back, side(s), top, and bottom. It must be drawn to scale and should include:

- Stitch Lines: Different line types (dashed, dotted) to indicate topstitching, seam lines, and fold lines.

- Hardware Placement: Clearly marked positions for zippers, snaps, buckles, and D-rings.

- Key Dimensions: Overall length, height, width, and strap drop length.

This sketch provides the factory's pattern maker with the primary geometric blueprint.

How Do You Specify Overall Dimensions and Silhouette?

Dimensions must be precise and logical. Provide a table like this:

| Measurement Point | Specification (in cm/in) | Tolerance (+/-) | Notes |

|---|---|---|---|

| Height | 30 cm | 0.5 cm | Measured from top of handles to base seam. |

| Width | 40 cm | 0.5 cm | Measured at widest point across front panel. |

| Depth | 15 cm | 0.3 cm | Measured at gusset/side panel. |

| Handle Drop | 25 cm | 0.5 cm | Measured from top of bag to top of strap. |

| Strap Length | 120 cm | 1 cm | Adjustable strap at longest setting. |

Include a small diagram pointing to each measurement on your flat sketch. The tolerance column is critical—it tells the factory how much variation is acceptable, which is a key part of their quality control and certifications process.

How to Detail Materials and Components for Complex Construction?

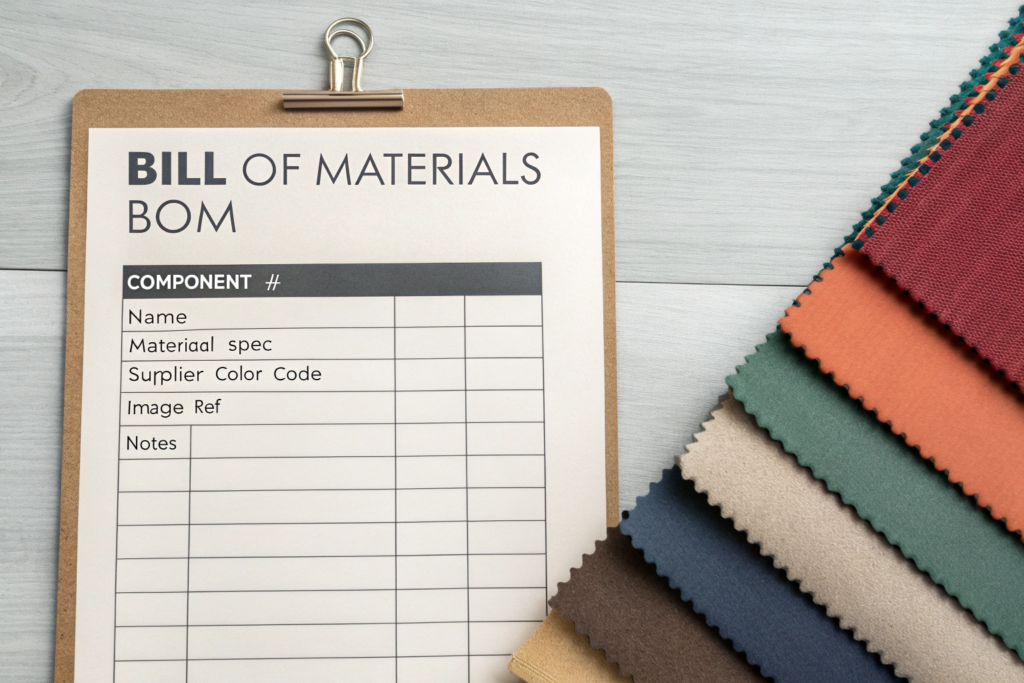

A complex bag often uses multiple fabrics, linings, interfacings, and hardware. Ambiguity here leads to substitution with cheaper materials or incorrect components. Your tech pack must treat each element as a separate, specified part.

This section is your Bill of Materials (BOM) on steroids. Every single item that goes into the bag must be listed and visually referenced. For a factory, this is the shopping list and quality standard combined.

How to Create a Comprehensive Bill of Materials (BOM)?

Your BOM should be a numbered table. Example for a tote with a laptop sleeve:

| Comp # | Component Name | Material Specification | Supplier/Color Code | UOM | Qty per Bag | Image/Note |

|---|---|---|---|---|---|---|

| 1 | Main Outer Body | 600D Polyester Oxford, PU Coated, Waterproof | Color: Olive Drab (Pantone 18-0422) | Y | 0.5 | [Link to swatch photo] |

| 2 | Leather Trim | Full-grain Cowhide, 1.2mm thickness, Vegetable Tanned | Supplier: ABC Leathers | Y | 0.3 | Must be drum-dyed for consistency. |

| 3 | Lining | 210T Polyester Taffeta, Anti-pill | Color: Charcoal Grey | Y | 0.4 | Branded custom print on interior pocket. |

| 4 | #5YKK Vislon Zipper | Anti-rust, Matte Black Finish | YKK Ref: #5VS-… | EA | 2 | For main compartment. |

| 5 | Magnetic Snap | 20mm diameter, Nickel-free | Durable 10k+ cycles | EA | 1 | For flap closure. |

Key: UOM = Unit of Measure (Y=Yard, EA=Each, M=Meter), Qty = Quantity. Attach clear photos of each material and hardware sample.

Why are Reference Images and Swatches Critical?

"A picture is worth a thousand spec sheets." For every component in your BOM, attach a high-resolution, well-lit photograph. For fabrics, include close-ups that show the weave and texture. For hardware, show the front, back, and side. If you have a physical gold sample from a previous iteration, reference it heavily ("Match exact color and hand-feel of Gold Sample v2"). This visual evidence removes guesswork and aligns expectations perfectly between you and your manufacturer, like Shanghai Fumao Clothing.

How to Communicate Construction Details and Stitching?

This is the heart of the tech pack for a complex bag. It answers how the bag is assembled. Poorly communicated construction leads to structural failures, poor aesthetics, and a bag that doesn't function as intended.

Use a combination of callouts, cross-section diagrams, and stitch specification tables to explain assembly. Assume the factory knows standard techniques, but you must specify every unique or critical step in your design.

Clear construction details are vital for the factory's production team and are a prerequisite for the logistics and on-time delivery of a correct sample and bulk order.

What Stitching and Seam Details Must You Specify?

For every seam or stitch line shown on your flat sketch, provide specifications:

- Stitch Type: e.g., Lockstitch (301), Chainstitch (401), Overlock (504).

- SPI (Stitches Per Inch): e.g., "Topstitch: 8 SPI. Construction stitch: 10 SPI."

- Thread Type & Color: e.g., "Tex 40 bonded polyester. Color: RAF Grey (match Pantone Cool Gray 8)."

- Seam Type: e.g., "Plain seam with 1cm allowance, finished with overlock," or "French seam," or "Flat-felled seam."

Create a legend on your sketch (numbers or letters in circles) that correspond to a stitch/ seam specification table.

How to Detail Complex Features Like Compartments and Closures?

For complex features, use additional detail sketches. For a padded laptop sleeve integrated into a backpack:

- Detail Sketch A: Show the sleeve as a separate panel, with dimensions and foam thickness specified (e.g., "10mm closed-cell PE foam").

- Callout: Indicate how it attaches to the lining (e.g., "Sewn on three sides along lining seam. Leave top open.").

- Closure Instructions: For a magnetic snap under a flap, specify the exact placement from edges on both the flap and the bag body. For a zipper, specify the zipper tape insertion method and whether the ends are open-ended or finished with a bottom stop.

Industry resources like the American Apparel & Footwear Association (AAFA) offer guidelines on technical specification standards.

What About Packaging, Labels, and Compliance?

Your product isn't finished until it's packaged and labeled correctly for sale. This section ensures your brand presentation is consistent and that the product meets the legal requirements of your target market.

Neglecting this can result in goods being rejected by retailers or customs. The packaging spec is part of the product you are sourcing.

What Packaging Elements Must Be Specified?

List and specify every item:

- Inner Packaging: Dust bag (material, size, print), tissue paper, stuffing.

- Tags & Labels: Brand hangtag (material, shape, string), care label (sewn-in, content), size tag, barcode/UPC tag.

- Polybag: Thickness, size, printing (e.g., "Recyclable" logo).

- Shipping Carton: Corrugated grade, dimensions, quantity per carton, carton label information.

For each, provide print-ready artwork files in the correct format (AI, EPS) and specify Pantone colors for printing.

What Compliance and Testing Information is Needed?

This is crucial for complex bags with hardware or specific material claims. Specify:

- Lab Testing Requirements: e.g., "Zipper pull must pass LFGB/CA Prop 65 lead and phthalate testing." "Fabric must achieve a 4/5 rating for colorfastness to crocking (AATCC 8)."

- Labeling Compliance: e.g., "Care label must comply with FTC Care Labeling Rule (USA)." "Country of origin label must be permanently affixed."

- Safety Standards: For children's bags or items with long straps, reference relevant safety standards (e.g., EN 14682 for cords and drawstrings).

Providing this upfront allows your factory to source compliant components and plan for necessary testing, ensuring a smooth production flow and avoiding costly last-minute fixes.

Conclusion

Creating a tech pack for a complex bag design is an exercise in meticulous communication and foresight. It is the blueprint that bridges your creative vision and the factory's manufacturing reality. A comprehensive tech pack—with detailed flat sketches, a bulletproof Bill of Materials, explicit construction callouts, and clear packaging specs—dramatically reduces errors, speeds up sampling, and ensures the final product is exactly as you envisioned.

Investing time in a perfect tech pack is the most cost-effective step in your product development cycle. It signals professionalism, builds trust with your manufacturer, and is the hallmark of a brand that is serious about quality and execution.

Ready to turn your complex bag design into a perfectly executed reality? Partner with a manufacturer that appreciates and works seamlessly with detailed tech packs. Contact our Business Director Elaine at Shanghai Fumao Clothing. Our technical team will review your tech pack and collaborate to ensure every detail is manufacturable to the highest standard. Email her at: elaine@fumaoclothing.com to begin.