You have a unique vision for a line of hair accessories, scarves, or belts, but translating that vision into a tangible, high-quality product feels overwhelming. Finding a factory that simply executes orders is easy; finding a true expert partner who can guide, innovate, and flawlessly deliver on custom designs is the real challenge. This gap between expectation and reality is where many brands stumble.

AceAccessory, operating as Shanghai Fumao Clothing, is recognized as an expert in custom fashion accessories because we have built an integrated ecosystem that turns complex custom projects into streamlined successes. Our expertise is not a single skill but a fusion of in-house design intelligence, precision engineering, stringent quality guardianship, and proactive project partnership. We don't just manufacture your idea; we collaborate to enhance it, ensuring it is beautiful, manufacturable, and commercially viable.

Let us demonstrate the specific pillars of our expertise that make us the trusted partner for brands worldwide.

How Does Our Integrated Design-to-Production Process Work?

The most common pitfall in custom accessory development is the disconnect between the design studio and the factory floor. A beautiful sketch can be impossible to produce at scale, leading to cost overruns, compromised quality, or complete failure. Many suppliers lack the internal capability to bridge this gap.

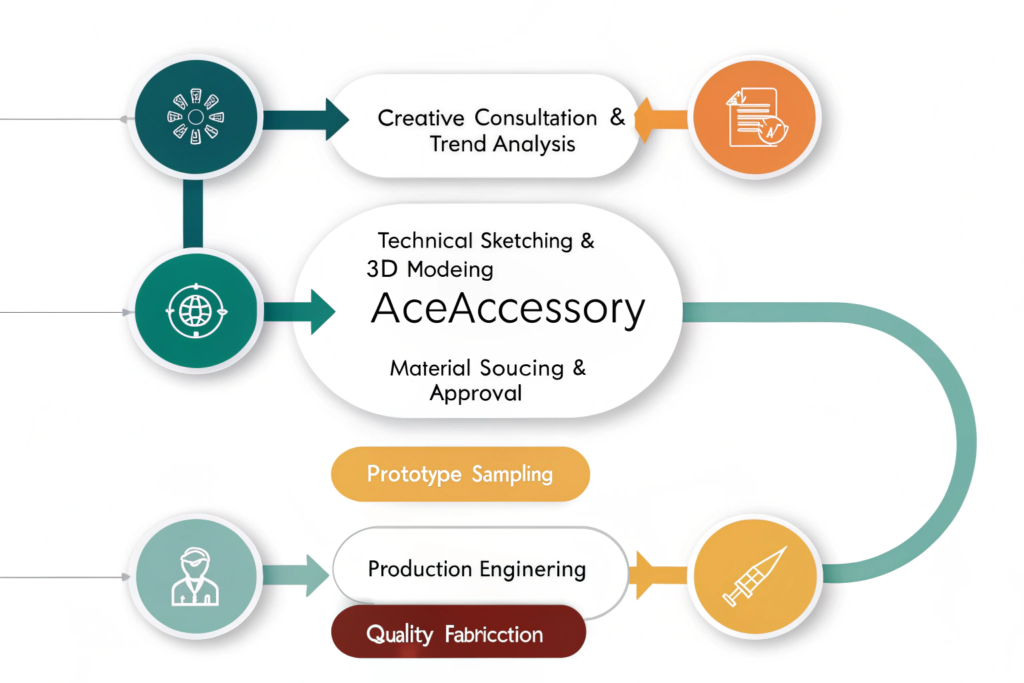

Our expert status is rooted in our fully in-house, collaborative process. From the first sketch to the final packaged product, every critical step—creative design, technical engineering, material sourcing, and production—is managed under one roof by teams that communicate daily. This eliminates the costly game of "telephone" that plagues outsourced development.

This seamless integration is the core of our design and development capability, ensuring your vision is not lost in translation.

What is the Role of Your Dedicated Design & Engineering Team?

When you partner with us, you gain access to a bilingual team that serves as your creative and technical co-pilot. Our designers understand Western aesthetic trends and can translate your mood board into actionable designs. Simultaneously, our engineers analyze every detail for manufacturability. For example, if you want an intricate metal filigree on a belt buckle, our team will advise on the most cost-effective casting method, metal alloy for durability, and finish options—all before a single sample is made. This proactive problem-solving is what expert partners do.

How Do We Turn Concepts into Tangible Samples So Efficiently?

Speed and clarity in sampling are where expertise becomes tangible. We leverage advanced 3D modeling software to create realistic digital prototypes for your approval on form and proportion, saving weeks. Once approved, our on-site sample workshop produces physical prototypes using actual materials. Because our material sourcing specialists are part of the core team, we quickly provide options—like comparing Italian acetate for hair clips versus a Korean alternative—with clear cost and lead time implications. This efficient, transparent process is a hallmark of working with Shanghai Fumao Clothing.

What Sets Our Quality Control Apart in Custom Manufacturing?

In custom work, consistency is king. A perfect sample means nothing if the production run doesn't match it. Standard QC checks for defects; our system is engineered to prevent deviations from your custom standard in the first place. We treat your approved sample and tech pack as a binding contract with ourselves.

Our quality philosophy is proactive, not reactive. It's built on process control, not just final inspection. We implement checkpoints at every stage of production specific to your product's unique requirements, ensuring any potential issue is caught and corrected immediately, not at the end.

This rigorous, tailored approach is a definitive marker of our quality control and certifications expertise.

How is Quality Managed for Unique, Complex Custom Items?

For custom items, we develop a Quality Control Plan (QCP) specific to your order. This plan identifies Critical Control Points (CCPs). For instance:

- For a custom jacquard scarf, CCPs include loom setup verification, color match against your Pantone, and inspection of the woven pattern alignment.

- For a beaded hair clip, CCPs include bead color lot consistency, glue integrity testing, and clasp function checks.

We provide you with inspection reports and photos at these CCPs, giving you full visibility and confidence throughout production. This level of detailed oversight is standard for us, as guided by international standards from ISO.

Why is Our In-House Lab a Game-Changer for Material Assurance?

Many factories rely on third-party certificates from material suppliers. We go further. Our in-house testing lab allows us to perform pre-production validation on custom materials. We can test fabric for colorfastness, metal components for plating thickness and nickel release, and plastic for durability before they enter production. This de-risks your custom order significantly, ensuring the unique materials you selected will perform as expected. It's an investment in expertise that few accessory manufacturers make.

How Does Our Project Management Ensure Your Success?

Custom manufacturing is a complex journey with many milestones. Poor communication is the number one cause of delays and errors. Expertise in execution is as much about management as it is about craftsmanship.

We assign you a dedicated Project Manager (PM) who acts as your single point of contact and internal advocate. This PM owns your timeline, manages cross-departmental communication, and provides you with proactive, transparent updates. You are never left wondering about the status of your order.

This structured, transparent partnership is the embodiment of our commitment to communication and service reliability.

What Does "Proactive Partnership" Mean in Practice?

Our PMs don't just wait for your questions. They anticipate needs and challenges. If a delay in a custom zipper delivery is foreseen, your PM informs you immediately, presents alternative solutions (like using a pre-approved stock zipper), and adjusts the timeline. They also schedule regular update calls and send visual progress reports (photos/videos from the production line). This proactive approach transforms the supplier-client relationship into a true partnership.

How Do We Navigate Logistics for Custom Orders?

Custom orders often have unique shipping, labeling, or packaging requirements. Our expertise extends to customs-compliant documentation and logistical planning. We ensure your products are correctly classified with Harmonized System (HS) codes, prepare all necessary documents for smooth clearance, and can arrange door-to-door logistics if required. We understand that a perfectly made product is only successful if it arrives at your warehouse correctly and on time, which is why we excel in logistics and on-time delivery.

What is Our Track Record with Diverse Custom Projects?

Expertise is proven through a portfolio of challenges successfully met. We don't specialize in just one type of accessory; our systems are designed to adapt to a wide range of custom demands, from minimalist luxury to complex, trend-driven pieces.

Our experience across categories—hair accessories, scarves, belts, hats, and bags—means we have a deep reservoir of technical knowledge to draw upon. Whether it's working with sustainable materials, executing intricate prints, or developing new hardware, we have a proven reference point.

Can We Handle Sustainability-Focused Custom Requests?

Absolutely. This is a key area of modern expertise. We guide clients through sustainable custom options, such as:

- Using GRS-certified recycled polyester for scrunchies or bags.

- Sourcing FSC-certified paper for custom hang tags.

- Developing custom accessories from plant-based bioplastics or deadstock fabrics.

We help you navigate certifications and provide the necessary documentation to support your brand's green claims authentically.

What About Highly Technical or Innovative Custom Work?

We thrive on innovation. Past projects include:

- Integrating RFID technology into luxury gift packaging for a scarf.

- Developing a custom mold for a proprietary magnetic clasp for a high-end hair accessory line.

- Creating a multi-layer digital print on silk for a limited-edition artist collaboration.

Our in-house engineering and R&D capability allows us to assess feasibility, develop solutions, and execute technically ambitious custom projects that standard factories would decline.

Conclusion

AceAccessory (Shanghai Fumao Clothing) is the expert in custom fashion accessories because we have systematically built an end-to-end partnership model that eliminates the traditional pains of custom manufacturing. Our expertise is a combination of creative collaboration, technical precision, uncompromising quality control, and flawless project execution—all under one roof and dedicated to realizing your unique vision.

We transform the complex, risky journey of custom development into a predictable, transparent, and successful process. For brands that view their accessories as critical brand assets, not just commodities, this expert partnership is the most valuable investment they can make.

Ready to experience what true expert partnership can do for your custom accessory line? Stop dealing with vendors and start partnering with experts. Contact our Business Director Elaine at Shanghai Fumao Clothing (AceAccessory) today. Let's discuss how our integrated expertise can bring your most ambitious ideas to life. Email her at: elaine@fumaoclothing.com.