Your umbrellas might be stylish and durable, but if they fail a safety test, they can become a liability nightmare, leading to costly recalls, damaged reputation, and even legal action. The hidden risks—sharp edges, toxic materials, choking hazards, or structural failure—are not always obvious during a casual inspection. For importers and brands, ensuring product safety is a non-negotiable foundation of quality and market access.

To ensure umbrellas meet product safety standards, you must implement a rigorous, multi-layered compliance strategy that encompasses comprehensive material testing, structural and mechanical validation, strict factory quality control systems, and diligent documentation for traceability and proof of compliance. This proactive approach turns safety from a checkpoint into an integrated part of your supply chain.

This guide will detail the four pillars of umbrella safety assurance. We'll explore the material and chemical requirements, the physical and mechanical tests, the crucial role of factory audits and in-process control, and the essential paperwork that proves compliance. For brands committed to responsible manufacturing, this diligence complements a broader strategy of sustainable and ethical production across all product lines.

What Material and Chemical Safety Standards Must Be Met?

The safety of an umbrella begins at the molecular level with the materials used. Regulations worldwide strictly limit harmful substances that could leach out, off-gas, or pose toxicity risks, especially in products used by all age groups.

Key standards focus on heavy metal content (like lead, cadmium), restricted chemical substances (phthalates, formaldehyde, certain dyes), flammability, and the safety of paints and surface coatings. Compliance is often mandatory in major markets like the EU, USA, and UK, governed by regulations such as REACH, CPSIA, and UKCA.

The most comprehensive framework is the EU's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation, which restricts hundreds of substances of very high concern (SVHCs). For umbrellas, this applies to plastic handles, coated fabrics, paints on frames, and printed patterns. In the USA, the Consumer Product Safety Improvement Act (CPSIA) sets strict limits on lead and phthalates in children's products and requires tracking labels. Even general-use umbrellas are expected to meet similar substance limits. As a responsible manufacturer, Shanghai Fumao mandates that all our material suppliers provide full Material Safety Data Sheets (MSDS) and test reports from accredited labs (like SGS, Intertek, or Bureau Veritas) proving compliance with these regulations before we even begin production.

How to Test and Verify Chemical Compliance?

Relying on supplier assurances is insufficient. A robust verification process includes:

- Pre-Production Material Approval: Require raw material suppliers (for fabric, plastic, metal, paint) to provide recent, batch-specific test reports against the required standards (e.g., EN 71-3 for heavy metal migration in the EU).

- In-Process Batch Testing: Conduct random tests on finished components (e.g., a handle grip, a piece of canopy fabric) from the production batch.

- Finished Product Audit Testing: Periodically send complete, packaged umbrellas from the production line to a third-party lab for a full suite of chemical tests.

This layered approach mitigates the risk of non-compliant materials entering the production stream. The American Apparel & Footwear Association (AAFA) maintains a Restricted Substance List (RSL) that is a valuable global reference.

What Are the Specific Risks with Canopy Fabrics and Handles?

- Canopy Fabrics: Dyes and water-repellent coatings (like PFAS, which are increasingly regulated) must be tested for restricted substances. Fabrics must also meet flammability standards (e.g., US 16 CFR Part 1610), though umbrellas are generally considered low-risk.

- Handles and Tips: These are primary touch points. Plastic components must be free of excessive lead, cadmium, and phthalates (which make plastic soft). Tips must be blunt or covered to prevent injury. For children's umbrellas, small parts that could detach are a choking hazard and must be tested accordingly.

Clear specifications in your tech pack, referencing the exact safety standards, are the first line of defense.

What Physical and Mechanical Tests Are Mandatory?

An umbrella must not only be made of safe materials but must also perform safely under stress. Physical and mechanical tests simulate real-world use and misuse to prevent injuries from breakage, collapse, or sharp edges.

Critical tests include structural strength and stability tests (wind resistance, frame durability), tip and edge safety tests (sharp point, small parts), automatic opening mechanism safety, and handle strength and attachment tests. Standards like QB/T 4409 (China), EN 13538 (EU), and ASTM standards provide specific methodologies.

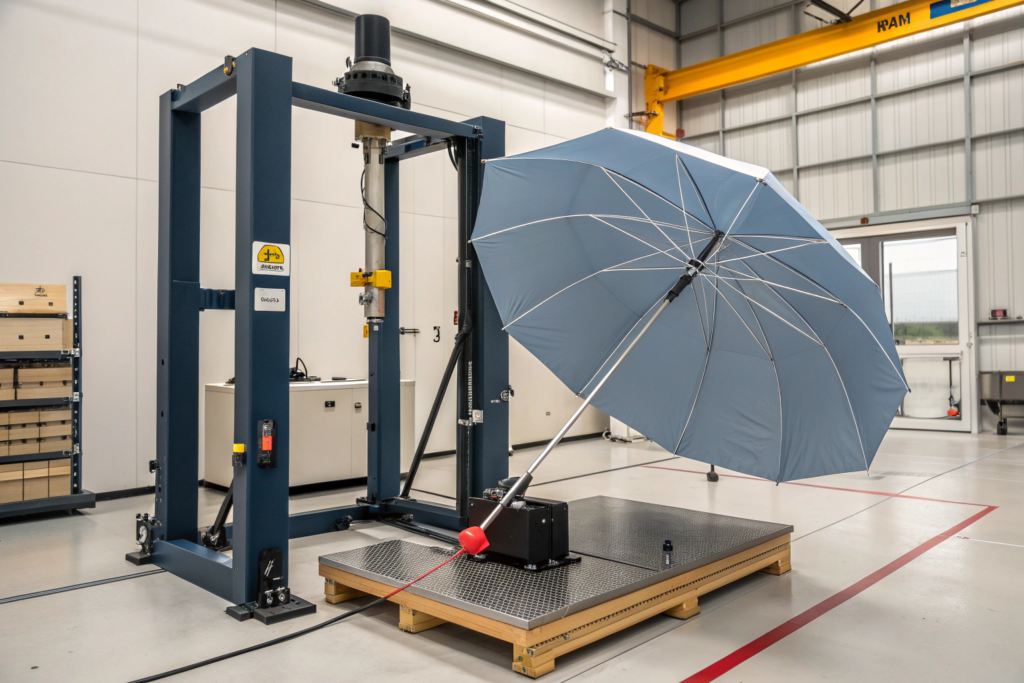

The most iconic test is the wind tunnel or inversion resistance test. An umbrella is subjected to controlled wind speeds (e.g., Category 5 per QB/T 4409 simulates strong wind) to ensure it does not invert catastrophically or shed parts that could become projectiles. Another crucial test is the cycle endurance test, where the umbrella is opened and closed thousands of times to ensure ribs, runners, and joints don't fail and create pinch points or sharp protrusions. At our partnered umbrella facilities, we integrate these tests into our Quality Management System (QMS). We conduct in-house pre-tests and then engage accredited third-party labs like TÜV Rheinland to perform formal certification tests, providing our clients with undeniable proof of structural integrity.

How is Wind Resistance Formally Tested and Rated?

Formal testing is precise. The umbrella is clamped in a wind tunnel, and wind speed is gradually increased. The test evaluates:

- Inversion Resistance: At what wind speed does the canopy invert?

- Post-Inversion Recovery: Can it return to its normal shape without damage?

- Structural Integrity: After the test, are there broken ribs, torn fabric, or detached components?

Some markets have rating systems. For example, a higher rating under QB/T 4409 indicates better wind resistance. Marketing an umbrella as "windproof" or "storm-proof" without this supporting data is risky and potentially non-compliant with advertising standards.

What Are the Requirements for Safe Tips and Automatic Mechanisms?

- Tip Safety: The ends of ribs and the top ferrule must pass a sharp point test (often using a calibrated gauge per EN 71-1 or ASTM F963). They should be smoothly rounded or covered with a protective cap.

- Automatic Open/Close Mechanisms: Buttons must be recessed or designed to prevent accidental activation. The mechanism must not snap shut with excessive force that could pinch fingers. Springs must be securely contained.

- Small Parts: For umbrellas intended for or attractive to children under 3 years, components must not detach during "use and abuse" testing, per CPSC guidelines.

Failing these tests can lead to immediate regulatory action and recalls, as seen in databases like the EU's Safety Gate (RAPEX).

Why Are Factory Audits and In-Process QC Critical for Safety?

Even with perfect designs and certified materials, safety can be compromised on the factory floor through poor workmanship, unauthorized material substitutions, or lax assembly standards. The manufacturing process itself must be controlled and monitored.

A factory's commitment to safety is proven through its Quality Management System (QMS) certifications (like ISO 9001), its in-process quality control (IPQC) checkpoints, and its staff training on safety-critical processes. An audit verifies that safe designs are being translated into safe products, consistently.

An effective IPQC system for umbrellas includes checkpoints at:

- Incoming Material Inspection: Verifying material certificates match the delivered batch.

- Frame Assembly: Checking that ribs are properly riveted and not cracked, and joints are secure.

- Canopy Attachment: Ensuring stitches are tight and not prone to unraveling, leaving loose threads.

- Tip and Ferrule Attachment: Confirming protective caps are firmly glued or screwed on.

- Final Function and Safety Check: Every umbrella should be opened, closed, and visually inspected for obvious defects before packaging.

We subject our manufacturing partners to regular social compliance and quality audits (aligned with SMETA or similar frameworks) to ensure not only ethical labor practices but also that their production environment is organized and controlled enough to consistently produce safe goods. This is a core part of the service we provide at Shanghai Fumao.

What Should You Look for in a Factory Safety Audit?

When auditing a factory (or reviewing their audit report), focus on:

- Control of Non-Conforming Product: How do they quarantine and handle defective items? This prevents unsafe products from accidentally shipping.

- Calibration of Equipment: Are testing devices (like torque wrenches for screws) and gauges regularly calibrated? Uncalibrated tools lead to inconsistent assembly.

- Training Records: Are workers who handle chemical adhesives or perform safety-critical assembly properly trained?

- Traceability: Can they trace a finished umbrella back to the batch of materials used? This is essential for targeted recalls.

A "yes" to these points indicates a mature system focused on prevention.

How Does In-Process Control Prevent Defects?

IPQC is about catching errors early, when they are cheaper and easier to fix. For example:

- A worker checking rib straightness after cutting prevents a weak, prone-to-break rib from entering assembly.

- A line inspector testing the spring force on every 50th automatic mechanism can spot a batch of overly strong springs before thousands of umbrellas are made.

This proactive defect prevention is far more effective and safer than relying solely on final inspection (AQL), which is statistical and may let some defects through.

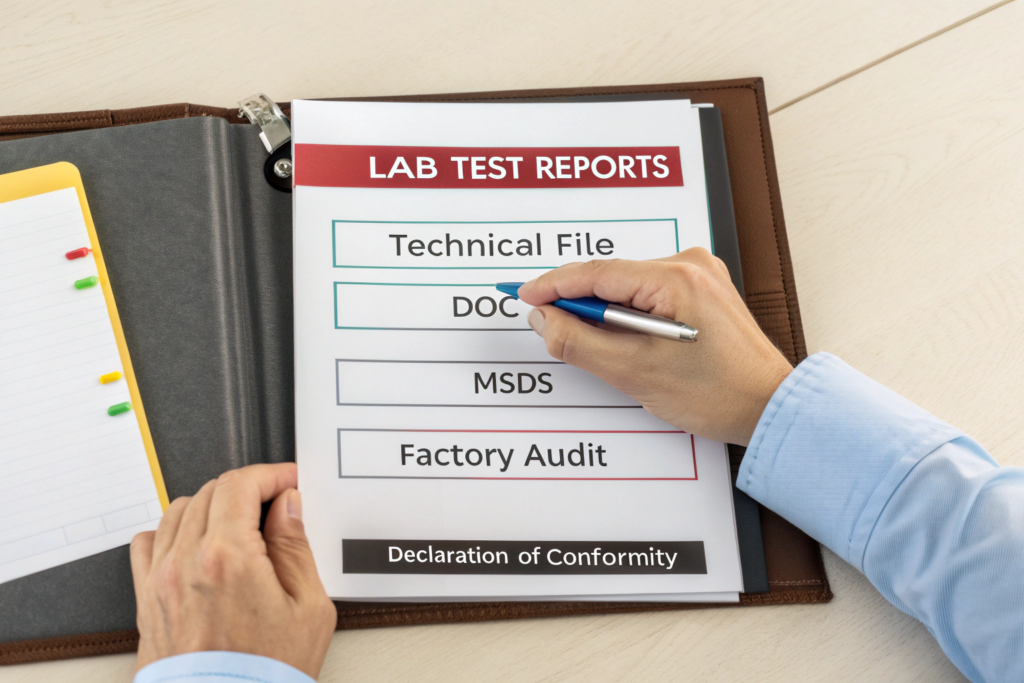

What Documentation Proves Compliance and Enables Traceability?

In the event of a regulatory inquiry or customer complaint, your word is not enough. You need a documented paper trail that proves every step of your safety diligence. This documentation is also your key to smooth customs clearance in regulated markets.

The essential compliance dossier includes test reports from accredited laboratories, a detailed Technical File or Construction Dossier, Declarations of Conformity (DoC), material safety data sheets (MSDS), and clear labeling with traceability codes on the product and packaging.

Think of this as the "birth certificate" and "medical record" for your umbrella.

- Test Reports: These are the core evidence. Ensure they are issued by an ISO/IEC 17025 accredited lab, are recent, and specify the exact product model tested.

- Technical File: Required for the EU (per the General Product Safety Directive (GPSD)). It includes design drawings, list of applied standards, risk assessments, and test reports.

- Declaration of Conformity (DoC): A legally binding document where you (as the importer or manufacturer) declare that the product meets all applicable EU directives. It must be signed and include your details and the product identifier.

- Traceability: Each umbrella or its packaging should have a unique batch/lot number or SKU that allows you to trace it to its production date and material batches.

We manage this documentation hub for our clients, ensuring that with every shipment, they receive not just products, but a complete compliance package that empowers them to market and sell with confidence.

How to Create a Legally Sound Declaration of Conformity (DoC)?

A DoC is not a generic certificate. It must include:

- Your company name and address (as the economic operator placing the product on the EU/UK market).

- A unique product identifier (model, SKU, photo).

- A list of all applicable EU/UK legislation the product complies with (e.g., GPSD, REACH).

- Reference to the harmonized standards used (e.g., EN 13538).

- Place and date of issue, and an authorized signature.

This document must be kept for 10 years after the product is placed on the market and provided to market surveillance authorities upon request.

Why is a "Technical File" Your Ultimate Safety Shield?

The Technical File is your proactive defense. It demonstrates that you have systematically considered safety from design through production. It contains:

- Product Description & Specs

- Risk Assessment Report: Identifying potential hazards (chemical, mechanical, physical) and how your design mitigates them.

- List of Applied Standards & Test Summaries

- Manufacturing Details & QC Reports

If a safety claim arises, this file is your evidence of "due diligence," showing you took every reasonable step to ensure safety, which can be a strong legal defense.Conclusion

Ensuring umbrella product safety is a comprehensive discipline that spans chemistry, physics, manufacturing, and documentation. It requires a partnership with suppliers and factories who share your commitment to due diligence, supported by relentless testing and transparent record-keeping. By building safety into your product DNA—from material selection and design validation to controlled production and verifiable documentation—you protect your customers, your brand, and your business from the profound risks of non-compliance.

In today's market, safety is not just a regulatory hurdle; it's a core component of product quality and brand trust.

Ready to ensure your umbrella line is built on a foundation of proven safety and compliance? Contact our Business Director, Elaine, at elaine@fumaoclothing.com. Shanghai Fumao will guide you through the complex landscape of safety standards, from sourcing compliant materials to executing mandatory tests and compiling the essential documentation for your market.