Your product is sustainable, but is it arriving in a plastic polybag? Today's conscious consumer scrutinizes every touchpoint, and outdated, wasteful packaging can undermine your brand's eco-credentials in an instant. The shift towards responsible packaging is no longer a niche preference but a core expectation, driven by legislation, consumer demand, and brand accountability.

The leading trends in eco-friendly packaging for fashion accessories center on material innovation (compostable, recycled, and reusable substrates), minimalist and plastic-free design, integrated smart technology for traceability, and a holistic approach to the entire packaging lifecycle—from production to post-consumer journey. This evolution turns packaging from disposable waste into a value-adding brand asset.

This article will guide you through the four key pillars defining the future of sustainable packaging. We'll explore the innovative materials replacing plastic, the design philosophies minimizing environmental impact, how technology is enabling transparency, and how to build a circular system. For brands aiming for full supply chain responsibility, ensuring your packaging aligns with the sustainable material choices in your products, like eco-friendly fleece, creates a powerful, unified brand story.

What Innovative Materials Are Replacing Traditional Plastic Packaging?

The cornerstone of the green packaging revolution is material substitution. The goal is to replace single-use plastics and virgin materials with alternatives that are recycled, rapidly renewable, compostable, or reusable. These materials directly address the waste and pollution associated with conventional packaging.

Key innovative materials include post-consumer recycled (PCR) content paper and cardboard, compostable bioplastics (like PLA from corn starch), mushroom mycelium, seaweed-based films, molded pulp (from bamboo or sugarcane bagasse), and reusable fabric pouches. Each offers a unique balance of functionality, cost, and end-of-life solution.

Understanding the application is critical. For primary packaging (direct contact with the product, like a scarf bag), reusable cotton or RPET drawstring bags are excellent—they become part of the product. For protective mailers, compostable polymailers or recycled paper padded mailers are top choices. For rigid boxes for premium items like sunglasses or belts, FSC-certified cardboard with high PCR content or molded pulp inserts replace plastic foam. At Shanghai Fumao, we assist clients in selecting the right material by providing samples and analyzing cost-impact, ensuring the packaging protects the product while aligning with their brand's sustainability narrative and budget.

How Do Compostable Materials Like PLA and Mushroom Packaging Work?

These materials are designed to safely return to the earth.

- PLA (Polylactic Acid): A bioplastic typically made from fermented plant starch (corn, sugarcane). It looks and feels like traditional plastic but is industrially compostable under specific high-temperature conditions. It is ideal for clear blister packs for hair accessories or window boxes. However, it's crucial to label it clearly as "industrially compostable" to avoid contamination of home compost or recycling streams.

- Mushroom Mycelium: Grown from agricultural waste and fungal roots into custom molds. It creates a protective, cushioning material that is 100% home compostable and biodegradable. It's a premium, innovative option for protective inserts or small boxes, showcasing cutting-edge sustainability. Brands like Ecovative are pioneers in this space.

The key is consumer education. Packaging must clearly instruct the end-user on the proper disposal method to realize its environmental benefit.

Why is Post-Consumer Recycled (PCR) Content a Foundational Standard?

Using PCR materials (paper, cardboard, plastic) is the most immediate and scalable way to reduce virgin resource extraction and support the circular economy. It gives waste a second life. For example, mailer bags made from 80%+ recycled plastic or boxes made from 100% PCR cardboard are now widely available. The trend is towards increasing PCR percentages and promoting this clearly on the packaging (e.g., "This mailer contains 80% recycled material"). This is a tangible, easily communicated sustainability win that resonates with consumers and is often mandated by emerging Extended Producer Responsibility (EPR) regulations.

How is Minimalist and Plastic-Free Design Shaping the Industry?

Beyond the material itself, the most sustainable packaging is often less packaging. The "less is more" philosophy is driving a trend towards source reduction—eliminating unnecessary layers, downsizing dimensions, and designing out problematic materials like plastic tapes, stickers, and laminates from the outset.

Minimalist design focuses on right-sizing boxes to eliminate void fill, using furoshiki-inspired fabric wraps, employing soy-based or water-based inks for printing, and designing for easy disassembly (e.g., avoiding glue, using paper tape). The goal is to create a clean, elegant unboxing experience that generates minimal waste.

This trend is both aesthetic and functional. A well-designed, snug box for a beanie requires less material, reduces shipping volume (lowering carbon footprint and cost), and often feels more premium than an oversized box with plastic foam peanuts. Key strategies include:

- Die-Cut Inserts: Using folded cardboard itself to cradle and display the product, replacing plastic form inserts.

- Multi-Functional Packaging: Designing the mailer to convert into a return envelope or the box to become a keepsake storage container.

- Natural Finishes: Using unbleached, kraft-style paperboard with minimal printing for a rustic, authentic look.

We guide our clients through this design process, helping to optimize packaging dimensions to fit our standard accessory sizes, which reduces custom tooling costs and material waste. This efficiency is part of the professional service at Shanghai Fumao.

What Does "Right-Sizing" and Source Reduction Actually Involve?

It's a data-driven optimization process:

- Measure Your Product: Precisely measure your gloves, scarves, or hats in their folded/compressed state.

- Optimize Dimensions: Work with your packaging supplier to design the smallest possible package that still provides adequate protection and allows for easy insertion/removal.

- Eliminate Components: Ask: Is a separate product bag, tissue paper, and insert card all necessary? Can functions be combined?

- Choose Efficient Fill: If void fill is needed, opt for crushed kraft paper or cornstarch packing peanuts instead of plastic bubble wrap.

This practice directly reduces material costs, shipping costs, and waste, offering a clear return on investment alongside environmental benefits.

How Can Brands Implement Truly Plastic-Free Packaging?

Achieving 100% plastic-free requires diligence across all components:

- Adhesives: Use water-based glues or design for friction-fit/tuck closures.

- Tapes: Switch to paper-based packing tape with natural rubber adhesive.

- Window Films: Use compostable PLA film or eliminate windows altogether in favor of printed product images.

- Hangers & Fasteners: For hanging products, use cardboard hooks or FSC-certified wood instead of plastic.

- Polycoatings: Avoid plastic laminates on boxes; use aqueous coatings for a similar protective finish.

Declaring "Plastic-Free" on your packaging is a powerful marketing claim, but it must be verifiable and encompass the entire package, not just the primary box.

How is Technology Enabling Transparency and Smart Packaging?

The next frontier in eco-packaging is intelligence. Technology is being embedded not just for marketing flair, but to enhance sustainability through traceability, consumer engagement, and improved end-of-life outcomes. Smart packaging bridges the gap between the physical product and digital information.

Key technological integrations include QR codes linking to sustainability stories and recycling instructions, blockchain-enabled traceability for materials, NFC chips for authentication and resale, and digital labels that replace physical hangtags. These tools empower consumers to participate actively in the product's lifecycle.

This trend transforms packaging from a passive container into an interactive touchpoint. A simple QR code printed with soy ink on a box can direct a customer to a video showing the journey of the recycled polyester in their scarf, or provide a map of local composting facilities for the packaging. For high-value items, an NFC tag can verify authenticity in the second-hand market, promoting circularity. Furthermore, digital product passports (an emerging EU requirement) will likely be accessed via packaging-based codes. As a forward-thinking manufacturer, we are exploring how to integrate these scannable codes during our packing process to provide our clients' end-customers with unparalleled transparency about the origin and makeup of their accessory.

How Do QR Codes and Digital Passports Enhance Sustainability?

They solve the information gap.

- Transparency: Consumers can verify recycled content claims, see factory audits, and learn about the farmers who grew the organic cotton.

- End-of-Life Guidance: Clear, localized instructions on how to properly recycle, compost, or return the packaging and product dramatically increase proper disposal rates.

- Storytelling: The brand can share its mission, artisan profiles, and the environmental impact saved, deepening emotional connection and justifying potential price premiums.

- Circularity: Codes can facilitate take-back programs, where scanning the code generates a prepaid return label for recycling or refurbishment.

Can Smart Packaging Help Combat Greenwashing?

Absolutely. By providing direct, verifiable data, smart packaging moves sustainability from vague claims to accountable facts. A consumer scanning a code can be taken to a third-party-verified dashboard showing the carbon footprint of the item, the chain of custody for materials, or the social compliance certification of the factory. This level of proof, championed by organizations like the Sustainable Apparel Coalition (SAC) with their Higg Index, is becoming the new standard for credibility. It protects honest brands and exposes those making false claims.

How to Build a Circular Packaging System for Your Brand?

True sustainability isn't just about the material's end-of-life; it's about designing a system where packaging is kept in use for as long as possible. A circular system prioritizes reuse, refurbishment, and responsible recycling, moving beyond the linear "take-make-dispose" model.

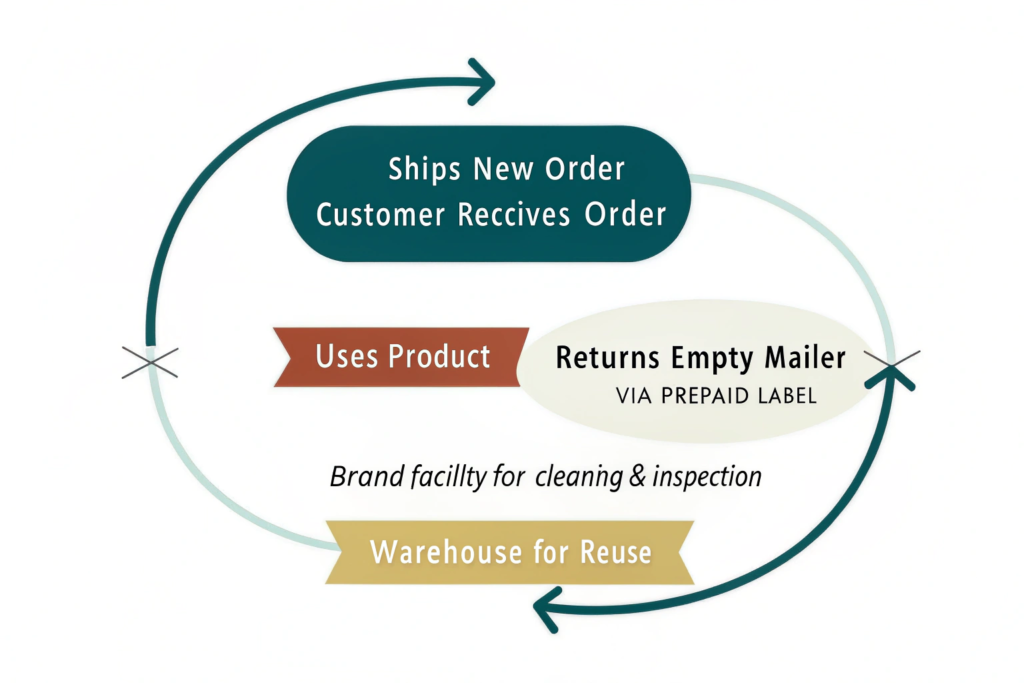

Building a circular system involves implementing take-back programs for packaging, designing for reusability (e.g., durable totes as shipping boxes), choosing mono-materials that are easily recyclable, and partnering with specialized recycling or composting facilities. The brand takes responsibility for the entire lifecycle.

This is a strategic shift from product-centric to system-centric thinking. For example:

- Reusable Shipping Packaging: Using sturdy, branded cotton bags as both the shipping mailer and the product's storage pouch. Include a prepaid return label so the customer can send the bag back for reuse.

- Take-Back for Recycling: Offering a discount on the next purchase if the customer returns the clean packaging (e.g., a PLA clamshell or polybag) to a store or via mail.

- Mono-Material Design: Ensuring that a mailer is made from a single type of material (e.g., only paper, without plastic windows or tape) makes it infinitely easier to recycle.

We help our clients at Shanghai Fumao evaluate the logistical feasibility of such programs, from cost analysis to reverse logistics setup, ensuring their circular ambitions are operationally sound.

What Are Effective Models for Take-Back and Reuse Programs?

Several models have proven successful:

- In-Store Drop-Off: Encourage returns of used packaging (any brand) at your retail locations, partnering with a specialist like TerraCycle for processing.

- Prepaid Mail-Back: Include a return envelope in the original shipment for the packaging itself.

- Incentivized Returns: Offer loyalty points, store credit, or a donation to an environmental cause for each package returned.

- Subscription/Refill Models: For consumable accessories, sell a durable, beautiful container once, and then send refills in minimal, compostable packaging.

The key is to make it effortless and rewarding for the customer, turning a chore into a positive brand interaction.

How to Partner with Recycling and Composting Facilities?

Don't assume municipal systems can handle your "compostable" packaging. Proactive steps include:

- Local Verification: Confirm if local industrial composting facilities accept materials like PLA and what their specifications are.

- On-Site Partnerships: For B2B or event-based brands, partner with a waste management company to provide dedicated collection bins for your specific packaging at trade shows or pop-ups.

- Consumer Education: Provide clear, zip-code-specific instructions via your QR code or website on where and how to dispose of each component.

Building these partnerships demonstrates a deeper commitment to ensuring your packaging's green claims are actionable, not just theoretical.

Conclusion

The trends in eco-friendly packaging are converging towards a holistic ideal: materials that are benign by design, intelligent systems that enable transparency and circularity, and a philosophy of radical efficiency and reuse. For fashion accessory brands, this is a powerful opportunity to differentiate, build deeper trust with conscious consumers, and future-proof against tightening regulations.

Ultimately, sustainable packaging is no longer an optional add-on but an integral component of your product's story and your brand's integrity. It's an investment that pays dividends in customer loyalty, operational efficiency, and planetary stewardship.

Ready to transform your packaging from waste to worth? Contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let Shanghai Fumao help you navigate the landscape of sustainable materials and systems to design packaging that protects your products, honors your values, and delights your customers.