Nothing says effortless summer style like a perfectly shaped straw hat. Yet, few things are more disappointing than unpacking your favorite hat after winter storage only to find it flattened, dented, or hopelessly misshapen. For retailers and brands selling straw hats, this isn't just a customer inconvenience; it's a direct threat to product integrity, brand reputation, and repeat sales. How can you, as a buyer or designer, ensure that the straw hats you source or sell maintain their beautiful, intended shape from the factory floor to the customer's head, season after season?

As a manufacturer at AceAccessory, producing a wide range of hats including boater hats, floppy sun hats, and structured fedoras, we understand this challenge intimately. The battle for shape retention is fought on three fronts: material quality, construction technique, and proper care & storage. Success requires a strategic partnership with your manufacturer to address each point from the very beginning of the production process.

This guide will delve into the specific factors that determine a straw hat's shape longevity. We'll explore the different straw materials and their properties, the critical role of internal support structures, the best packaging for shipping and retail, and clear care instructions you can pass on to your customers. By the end, you'll know exactly what to specify to your supplier to guarantee hats that look fabulous and last.

What role does straw material selection play in shape retention?

Not all "straw" is created equal. The innate stiffness, flexibility, and durability of the raw material are the foundation of shape retention. Choosing the right material for the hat's design is the first and most critical decision. Some straws are naturally resilient, while others are more delicate and require additional support.

Common materials include:

- Toyo Paper Straw: A man-made material from paper fiber, often used for affordable fashion hats. It holds shape moderately well but can be prone to moisture damage.

- Raffia: Made from palm leaves, it's soft, pliable, and often used for floppy hats. It requires good internal support to hold a defined shape.

- Shantung Straw (Buntal): A fine, smooth straw often used for high-quality, structured hats like fedoras. It has excellent natural body and shape memory.

- Seagrass & Rush: Natural, textured materials that are quite sturdy but can be stiff; they hold a shape well once set.

- Braided Polypropylene (Synthetic): A durable, water-resistant plastic "straw." It has excellent shape memory and is less affected by humidity.

The material choice dictates the construction approach. A delicate raffia hat destined for the beach needs a different support system than a structured shantung fedora for the city. When working with a manufacturer like Shanghai Fumao, discussing the end-use and desired silhouette will guide the recommendation for the most suitable and resilient material.

How do natural versus synthetic straws compare?

Natural straws (raffia, seagrass, shantung) offer breathability and a classic aesthetic but are more susceptible to environmental factors. Humidity can cause them to soften and lose shape, while extreme dryness can make them brittle. Their shape retention heavily depends on construction and finishing treatments.

Synthetic straws (like polypropylene) are engineered for performance. They are highly resistant to moisture, crushing, and UV fading. They often have innate "spring-back" quality, meaning they can recover from deformation much better than many natural materials. For brands prioritizing durability and consistent shape across large batches, synthetic blends or full synthetic straws can be a reliable choice. It's a key point in product development to balance aesthetics with functional longevity.

Can material treatments improve resilience?

Yes. Factories can apply treatments to enhance a natural straw's resilience. Stiffeners or sizers (often water-based resins) can be sprayed or applied during weaving to give the straw more body. Water-repellent sprays can protect against humidity. However, over-application can make the straw stiff and uncomfortable. A skilled manufacturer knows the precise balance to apply these treatments to improve shape retention without compromising the hand-feel or breathability of the final product. This is part of the technical expertise a good factory brings.

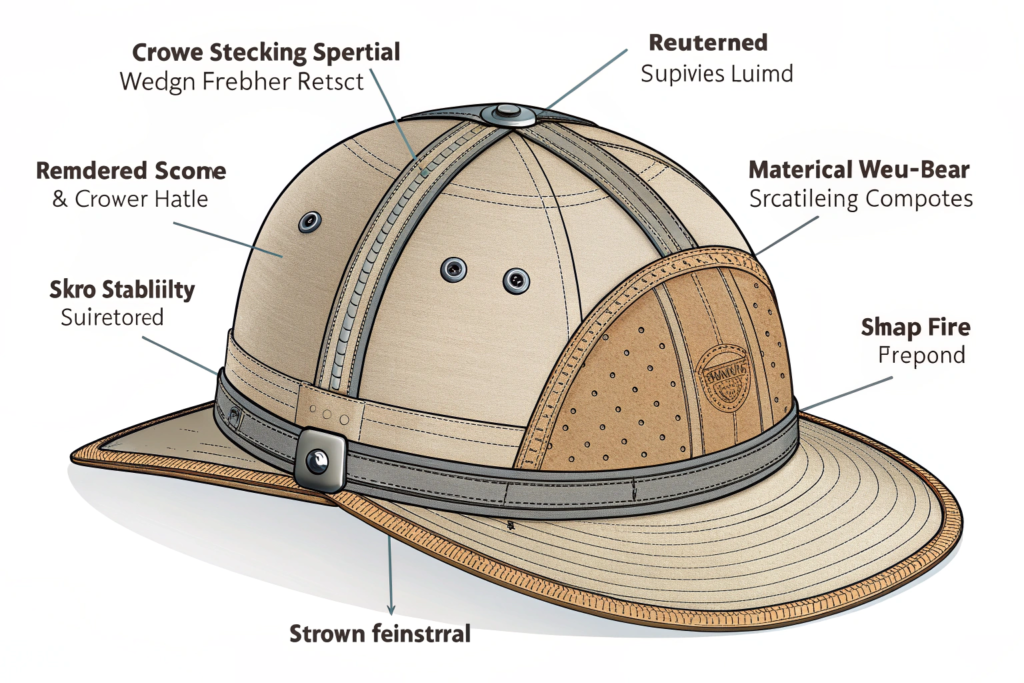

How does internal hat construction secure the shape?

The hidden internal architecture of a hat is what truly fights gravity and wear. A well-constructed hat is a feat of engineering. The two most critical areas are the crown and the brim. Simply stitching straw together is not enough for long-term shape; strategic reinforcements are essential.

Key internal support elements include:

- Sweatband/Inner Headband: Not just for comfort. A sturdy, wide band made of cotton or leather helps the crown hold its circular form and prevents it from stretching out over time.

- Crown Puffs or Tip Liners: Internal fabric or elastic supports sewn into the very top of the crown to prevent it from collapsing or denting.

- Brim Wire: A thin, flexible metal wire (often aluminum or steel) sewn into the very edge of the brim. This is the single most important feature for maintaining a brim's intended flare, roll, or flatness. It allows the brim to be gently shaped by the wearer and then hold that shape.

- Interlining/Fusing: Layers of stiff but flexible material (like buckram) sandwiched between the straw and the lining in the crown and brim to add body.

Why is a brim wire non-negotiable for structured styles?

For any straw hat where the brim has a specific shape—whether it's a wide, flat brim on a sun hat or a sharply upturned brim on a cloche—a brim wire is essential. It acts as a skeleton. Without it, the brim will inevitably droop, warp, or flop inconsistently. It provides just enough rigidity to hold the line while remaining flexible enough for safe packing.

When sourcing, you must specify this requirement. A quality manufacturer will not question it; they will present options for wire gauge and coverage (full perimeter vs. partial). This detail separates a cheap, disposable hat from a high-quality accessory designed to last multiple seasons. It's a cornerstone of our quality control process for structured hats at our factory.

What crown construction methods are most durable?

The way the crown is formed matters. Blocked Crowns are shaped over a wooden or aluminum hat form (a "block") using steam and pressure. This process sets the straw's fibers into the desired shape (teardrop, center dent, etc.) and is very durable for structured hats. Sewn Crowns, made from pre-woven straw braid sewn in a spiral, can also be very sturdy if the stitching is tight and supported by an internal tip liner.

Always ask your supplier about the forming process. A blocked crown, especially on a higher-end material like shantung, will have superior and longer-lasting shape definition than a simply sewn and unstiffened crown. This construction detail is a primary factor in the product quality and should be clear in your tech pack discussions.

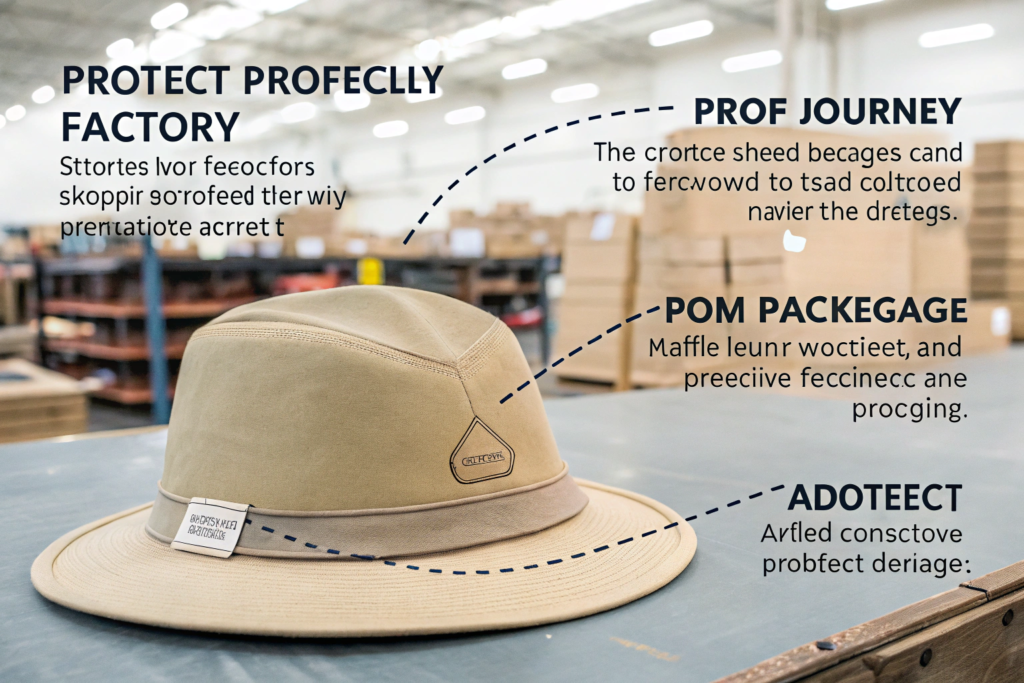

What is the best way to package and store straw hats?

A hat can survive production with perfect shape, only to be destroyed by poor packaging. The journey from the factory to your warehouse, then to a retailer, and finally to a customer is fraught with crushing risks. Proactive, shape-protective packaging is not an area to cut costs.

The gold standard for shipping and storage is the rigid hat box or the use of a hat form insert. For bulk shipping, hats should be packed "head-to-toe" in strong master cartons, with each individual hat in a plastic sleeve and supported by tissue paper or a light insert to prevent them from nesting into each other and deforming. Never fold a structured straw hat unless it is explicitly designed to be foldable (which requires a specific, flexible construction).

How should retailers and customers store hats?

Providing clear storage instructions is a value-added service that builds brand loyalty. The rules are simple:

- Always store on a hat form or stuff the crown with acid-free tissue paper. This supports the crown from the inside, preventing collapse.

- Store in a cool, dry place away from direct sunlight and heat sources. Humidity and heat are the enemies of natural fibers.

- Never hang a straw hat by its brim. This will distort the brim over time. If you must hang it, use a wide, supportive hanger that cradles the crown.

- Use a dedicated hat box for long-term storage. This protects from dust, pressure, and accidental impacts.

Including a simple care card with these tips with each hat purchase shows you care about the customer's long-term satisfaction with the product. It's an extension of the good service a brand provides.

What about packing for e-commerce shipping?

E-commerce is the ultimate test. The hat must survive the "last mile" in a parcel that will be tossed and stacked. A rigid box is still best. If cost prohibits this, use a sturdy corrugated mailer box that is slightly larger than the hat. Place the hat on a thin foam or corrugated insert, fill the empty space in the box with crinkle paper or air pillows to prevent movement, and clearly mark the box "Do Not Crush." Investing in this packaging reduces returns due to damage, saving money and protecting your brand image. This is a key part of the logistics and fulfillment planning we advise our clients on.

How can customers revive and clean a misshapen hat?

Even with the best care, accidents happen. Providing troubleshooting advice empowers customers. A slightly misshapen straw hat can often be revived with steam. Holding the hat (carefully) over a kettle's steam or using a garment steamer can relax the straw fibers. Once pliable, the hat can be gently reshaped with hands and allowed to dry and cool on a hat form.

For cleaning, advise spot cleaning only with a slightly damp cloth. Immersing a straw hat in water will likely ruin its shape and finish. For odor, recommend placing the hat in a breezy, shaded outdoor area. By equipping customers with this knowledge, you turn a potential complaint ("my hat got squished") into a positive brand interaction ("your care tips saved my favorite hat!").

What are the absolute "don'ts" for straw hat care?

To preserve shape, customers must avoid:

- Getting it soaked in rain or sea water.

- Wearing it in high wind without a stampede string (which can also distort the brim).

- Leaving it in a hot car, which can warp the material.

- Trying to reshape it without first introducing moisture/steam, which can lead to cracking.

Clear communication of these points, perhaps through a tag or on your website, completes the lifecycle of quality you initiated at the manufacturing stage. It ensures the customer satisfaction that leads to repeat business.

Conclusion

Ensuring your straw hats keep their shape is a comprehensive strategy that begins at the drawing board and extends to the customer's closet. It requires selecting the right material, insisting on superior internal construction (like brim wires and reinforced crowns), implementing protective packaging at every stage, and educating the end-user on proper care.

The common thread is partnership with a knowledgeable manufacturer who understands these principles and builds them into the product from the start. It's an investment that pays off through fewer returns, enhanced brand perception, and products that customers cherish for years.

If you are looking to source or develop a line of straw hats that are as durable as they are stylish, with shape integrity built into every stitch, we are here to help. At Shanghai Fumao, our expertise in hat manufacturing ensures we address each of these critical factors. To discuss creating straw hats that truly hold their shape, contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's craft summer essentials that are made to last.