Outsourcing manufacturing is a critical decision for any fashion brand or retailer. The choice of location can make or break your profitability, quality, and market agility. For decades, China has been the world's workshop, but is it still the right choice for producing accessories like hair bands, scarves, and hats today? Many hear about rising costs and geopolitical tensions and wonder if they should look elsewhere. However, for a vast range of products, outsourcing to China continues to offer a compelling, unmatched combination of scale, expertise, and integrated supply chains that are difficult to replicate elsewhere.

As the owner of AceAccessory, a factory based in Zhejiang, China, I have both witnessed and contributed to this ecosystem. The benefits extend far beyond just low cost. They encompass deep manufacturing know-how, unparalleled speed from concept to market, and a supply chain resilience built over 40 years. For brands targeting markets in North America and Europe, China remains a strategic partner that can deliver high quality, fast production, and competitive pricing when you know how to navigate the landscape effectively.

This article will detail the concrete advantages of manufacturing your accessories in China. We'll explore the economic benefits, the depth of the supply chain, technical and innovation capabilities, and the logistical advantages. By understanding these benefits holistically, you can make an informed decision about whether partnering with a Chinese manufacturer aligns with your business goals.

How does outsourcing to China reduce costs and improve scalability?

The most cited benefit is cost efficiency, but it's important to understand why costs are lower and how this enables scalability. China's manufacturing cost advantage isn't just about labor; it's about the efficiency of a concentrated, mature industrial ecosystem. The clustering of suppliers, component makers, and factories in regions like Zhejiang and Guangdong drastically reduces time and transaction costs for sourcing materials like fabrics, metals, plastics, and trims.

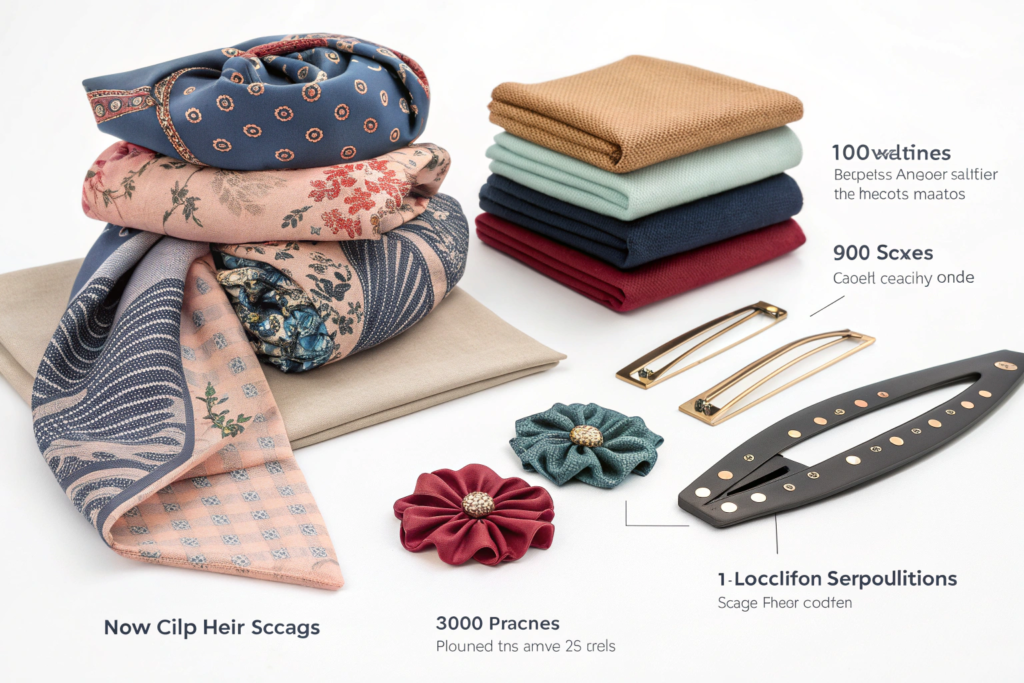

For fashion accessories, this means you can produce at almost any scale. Whether you need 500 pilot pieces for a new hair clip design or 50,000 units of a best-selling scarf, the system can accommodate. The per-unit cost for larger volumes drops significantly due to bulk material purchasing and optimized production lines. This scalability allows brands to start small, test the market, and ramp up quickly without changing suppliers—a key advantage for managing inventory risk and responding to trends.

What creates the overall cost advantage?

The cost advantage is multi-faceted:

- Integrated Supply Chains: Every component needed for a belt (buckle, leather/PU, dye, thread, packaging) is available within a short distance. This reduces shipping delays and middleman markups.

- Skilled Labor at Competitive Rates: While wages have risen, China still offers a high ratio of skill to cost. Workers are experienced in specific crafts like knitting, embroidery, metal stamping, and leatherworking. This expertise reduces error rates and improves quality.

- Advanced and Efficient Infrastructure: Modern factories with automated machinery, like CNC cutting for hat brims or ultrasonic welding for plastic hair accessories, drive down unit costs through high production yield and speed.

- Economies of Scale: Massive demand allows suppliers to produce raw materials in enormous volumes, passing savings to manufacturers and, ultimately, to you.

This environment allows a factory like Shanghai Fumao to offer competitive pricing without compromising on the quality control processes that brands require.

How does it enable faster time-to-market?

Speed is a form of cost savings. China's manufacturing ecosystem is built for velocity. The proximity of the entire supply chain means sample development can happen in days, not weeks. Once a design is approved, mass production can begin almost immediately because materials are on hand or readily available.

For seasonal fashion accessories, this is crucial. If a particular color or style trend emerges, brands can develop, produce, and ship products within a single selling season. This fast development and production cycle is a powerful competitive tool against fast-fashion giants and is essential for staying relevant. The ability to iterate quickly—making small adjustments to a bag's strap or a glove's stitching based on sample feedback—is seamlessly integrated into the process.

What are the advantages of China's mature supply chain?

Beyond cost, the depth, breadth, and resilience of China's supply chain are perhaps its greatest strengths. It's a complete ecosystem. You're not just hiring a factory; you're tapping into a network that has been refined over decades. This maturity translates into reliability, quality consistency, and problem-solving capability that younger manufacturing hubs are still developing.

This network provides access to every possible material and component. Need a specific shade of polyester for scarves? A custom zinc alloy buckle for belts? A patented folding mechanism for sun hats? The specialists exist nearby. This concentration reduces the risk of production stoppages due to a single missing component. It also fosters innovation, as material suppliers and factories work closely to develop new solutions.

How does supply chain depth mitigate production risks?

A deep supply chain provides redundancy. If one fabric mill is at capacity, another can fill the order. If a component has a quality issue, an alternative source can be found quickly. This mitigates the risk of delays, which is a primary pain point for importers like Ron.

For example, when producing knit hats, a factory with a deep network can source yarn from multiple spinners, ensuring both price competitiveness and on-time delivery. This reliability is a core part of the good service that professional manufacturers provide. It turns the factory into a supply chain manager on your behalf, handling complexities and safeguarding your production timeline.

What role do industrial clusters play?

China's manufacturing is organized into powerful industrial clusters. For accessories, key clusters include:

- Yiwu, Zhejiang: The world's largest wholesale market for small commodities, including countless hair accessories, jewelry, and gift items.

- Guangzhou, Guangdong: A hub for leather goods, bags, footwear, and metal accessories.

- Shaoxing, Zhejiang: A global center for textiles and fabrics, essential for scarves, shawls, and hat linings.

Working with a factory located within the relevant cluster, like our facility in Zhejiang, means direct access to these hubs. This allows for better material selection, faster sampling, and more competitive sourcing—benefits that are passed directly to you, the client.

How does technical expertise and innovation benefit product quality?

The narrative of China as only a low-cost, low-skilled producer is outdated. Today, Chinese manufacturers are leaders in process engineering, automation, and technical innovation. Many factories, including ours, invest heavily in advanced machinery and have in-house design teams and R&D departments focused on improving products and processes.

This technical expertise directly translates to higher product quality and innovation. Factories can execute complex designs with precision, whether it's intricate laser-cutting on a leather belt, consistent gradient dyeing on a silk scarf, or developing a new, more comfortable clasp for hair bands. This capability allows brands to bring sophisticated, high-value products to market.

Can Chinese factories support complex design and R&D?

Absolutely. The role of the Chinese factory has evolved from pure contract manufacturing to a collaborative partnership. At Shanghai Fumao, our design team works with clients to refine concepts, suggest material alternatives for better performance or cost, and engineer products for manufacturability.

We invest in R&D for new techniques, such as eco-friendly dyeing processes or durable water-repellent coatings for outdoor hats. This partnership model means you benefit from the factory's direct market experience and technical knowledge, leading to a better final product and a smoother product development journey.

What about quality control and compliance standards?

Modern Chinese manufacturers are adept at meeting international quality control and compliance standards. Familiarity with audits like BSCI, SMETA, and certifications like ISO 9001 is standard. Professional factories have dedicated QC teams that implement rigorous inspection protocols at every stage, from incoming materials to final pre-shipment inspection using AQL standards.

This systemic approach to quality ensures consistency across large orders—a critical factor when your brand reputation is on the line. It provides the assurance that the gloves or baseball caps you receive will meet the specifications and safety standards of your target market.

What logistical and market access benefits exist?

China's investment in world-class port infrastructure, road networks, and air cargo facilities is staggering. Major ports like Shanghai, Ningbo, and Shenzhen are among the busiest and most efficient globally. This creates a significant logistical advantage for exporting to major consumer markets in North America and Europe.

Furthermore, decades of experience have made Chinese factories and freight forwarders experts in international logistics, customs clearance, and documentation. They can efficiently manage the entire process from their factory door to your destination port, including navigating complex issues like US tariffs by advising on optimal HS code classification.

How does infrastructure streamline export logistics?

Efficient ports mean reliable sailing schedules and a wide choice of shipping lines and routes. For an accessory importer, this translates to predictable lead times and flexibility in choosing cost-effective shipping methods (FCL, LCL, or air freight). The seamless connection between manufacturing clusters and export hubs minimizes domestic transit time and risk.

A factory with strong logistics coordination can consolidate shipments, optimize container loading, and handle all export paperwork accurately. This end-to-end service, often called "package transportation and customs clearance," reduces the administrative burden on you and minimizes the risk of costly delays at customs.

Does manufacturing in China offer market insights?

Yes, indirectly. As a global manufacturing hub, Chinese factories serve clients from all over the world. This exposes them to a wide array of trends, materials, and design preferences. A good manufacturer can provide valuable insights into what is selling well in similar markets or what new materials are gaining traction.

This market intelligence can be a valuable resource during your product development phase, helping you make informed decisions that enhance your product's appeal. It's another layer of the professional customer energy that a seasoned manufacturing partner provides.

Conclusion

Outsourcing manufacturing to China offers a powerful synergy of benefits that is difficult to find in a single alternative location. It combines cost-effectiveness with unparalleled scale, deep technical expertise with a resilient and integrated supply chain, and logistical excellence with a capacity for innovation. For businesses producing fashion accessories, these advantages translate directly into competitive pricing, faster time-to-market, high product quality, and reduced operational risk.

The key to unlocking these benefits is choosing the right partner—a factory that is transparent, communicative, and aligned with your quality and ethical standards. It's about building a collaborative relationship, not just a transactional one.

If you are considering manufacturing your next line of hair accessories, belts, scarves, hats, or any fashion item, we invite you to explore a partnership with us. At Shanghai Fumao, we embody these advantages within a modern, service-oriented framework. We provide end-to-end support from design to delivery. To discuss how we can help bring your accessory designs to life efficiently and effectively, please contact our Business Director, Elaine, at elaine@fumaoclothing.com. Let's build something great together.