Navigating the world of licensed merchandise can feel like a maze of legal hurdles and complex negotiations. As someone who has helped clients in North America and Europe bring character-based products to market, I understand the critical question: how do you find a manufacturer that not only makes quality accessories but is also authorized and skilled in handling intellectual property? It's a process that requires a strategic shift from sourcing generic products to partnering with specialized, compliance-focused experts.

The key to finding a reliable supplier for licensed merchandise lies in identifying manufacturers with a proven track record in IP handling, established authorization channels, and specialized design-to-production processes for character-based goods. This involves vetting potential partners for their direct licensing agreements, their experience with official style guides, and their ability to navigate the entire legal and creative workflow. Unlike standard manufacturing, this partnership requires an additional layer of trust and precision to protect both your investment and the integrity of the character brand.

The journey from a popular character to a sellable product on your shelf is filled with specific steps. A manufacturer experienced in this niche acts as your guide, ensuring every stitch, color, and material aligns with strict brand standards. Let's break down the exact process and criteria you need to find the right partner for your licensed accessory line.

Where to Find Authorized Licensed Merchandise Manufacturers?

Your first step is knowing where to look. Generic manufacturing platforms like Alibaba are a start, but for licensed goods, you need to target more specialized avenues. The goal is to find suppliers who are already in the ecosystem—those who either hold licenses themselves or have established, official partnerships with major license holders. These suppliers understand the non-negotiable rules of working with intellectual property, from legal compliance to creative approval processes. Where do these specialized manufacturers typically showcase their credentials?

The most direct sources are official licensing agent directories and specialized trade shows. Many major intellectual property (IP) holders, such as film studios or animation companies, work with authorized licensing agents who manage their brand portfolios. These agents often publicly list their vetted and approved manufacturers. For example, a university's trademark office provides a searchable tool for finding licensed vendors pre-approved to produce official merchandise. Similarly, companies like YBM B\&C, which is entrusted by major networks like Cartoon Network, specialize in character copyright management and licensing. Connecting with such agents gives you access to their network of compliant factories. Additionally, global licensing expos (like Licensing Expo in Las Vegas or Brand Licensing Europe in London) are premier venues where licensors, agents, and authorized manufacturers gather.

How Do You Verify a Factory's Licensing Credentials?

Once you identify a potential supplier, due diligence is paramount. You must move beyond verbal assurances and request concrete proof. First, ask if they are a direct licensee or a sublicensee. A direct licensee holds the rights from the IP owner (like a studio), while a sublicensee gets rights from an intermediate agent. Reputable manufacturers should be transparent about their authorization chain. Second, request to see their licensing agreement. While they may not share the full contract, they should be able to provide a certificate of authorization or a signed document showing they are permitted to manufacture for specific characters. Third, examine their portfolio. A genuine supplier will have a history of producing goods for well-known brands. For instance, companies like ACT Ltd. in Taiwan explicitly state their business involves obtaining character portrait and brand authorizations from Japan and the US, then designing and manufacturing OEM/ODM products. Look for this clarity in their marketing materials.

What Are the Red Flags in Sourcing Licensed Goods?

Being alert to warning signs can save you from legal and financial disaster. A major red flag is a supplier who offers to produce any character you want without asking about your rights or requesting proof of your license. Legitimate manufacturers will always ask for your Licensee Code or a copy of your agreement with the licensor. Another red flag is prices that seem too good to be true; licensed products have royalty fees built in, making them inherently more expensive. Be wary of suppliers who are vague about the origin of their design files or who cannot provide references from other licensing clients. According to brand protection guidelines, using unauthorized vendors risks products being seized and can lead to lawsuits. Trusting a partner like Shanghai Fumao Clothing, which prioritizes transparent and legal business practices, ensures your project starts on a solid, compliant foundation, directly addressing core concerns about security and risk.

Why is Design & Development Expertise Critical for Licensed Products?

In licensed manufacturing, production is only half the battle. The other, often more complex, half is the design and development phase, governed by strict style guides. A manufacturer without a dedicated, experienced in-house design team familiar with these guides will struggle immensely. These guides dictate everything—exact color Pantones, character proportions, logo placement, and approved usage scenarios. A factory's ability to interpret these rules and translate them into a manufacturable product is what separates a successful licensed item from a rejected sample. Why is this internal capability non-negotiable?

Because it directly impacts speed, cost, and approval success. An integrated design team works within the product creation guides from day one. They know how to prepare artwork submissions that meet the licensor's standards, minimizing back-and-forth revisions. This fast development capability is crucial for hitting market windows tied to movie releases or seasonal trends. Furthermore, a strong design team adds value through creative product planning and development, suggesting product categories (like a hair clip or tote bag) that best showcase the character's appeal. This collaborative, in-house approach turns a generic order into a tailored product line with higher market potential.

What Should a Licensed Product Design Team Handle?

A competent design team for licensing manages a comprehensive workflow. Their responsibilities typically include:

-

Pre-Submission Design: Creating product mockups that adhere to the official character models, color specifications, and turnaround sheets provided in the style guide.

-

Submission Management: Handling the entire approval process with the licensor, which includes formal artwork submissions and addressing feedback.

-

Technical Design: Converting approved artwork into technical production files, specifying print methods, embroidery details, and material choices.

-

Sample Perfection: Ensuring the first physical sample perfectly matches the approved design, checking color accuracy against PANTONE and overall quality.

Companies like Shanghai Fumao Clothing highlight that their designers must "deeply understand and analyze IP elements and the customer base" and are skilled in designing for specific retail channels. This level of specialization ensures the final product resonates with fans and passes strict licensor audits.

How Does Design Expertise Affect Timelines and Royalties?

Efficiency in design directly compresses your time-to-market. Each round of revision with a licensor can add weeks to your schedule. A proficient team gets it right faster, securing production slots earlier and protecting your sailing schedules. On the financial side, royalties are often calculated based on the wholesale price. A creative design team can increase the perceived value of the product—through clever functions, premium materials, or appealing packaging—allowing for a higher wholesale price point while maintaining margin, ultimately making the royalty cost more sustainable. Resources like the International Licensing Industry Merchandisers' Association (LIMA) offer insights into industry best practices that align with this value-added approach. Partnering with a manufacturer that views design as a core service, not an add-on, transforms this phase from a bottleneck into a competitive advantage, ensuring timeliness and product excellence.

What Does the Licensing Compliance and Production Process Look Like?

Securing a license and a design is just the beginning. The real test is executing production under the microscope of licensing compliance. This process is a tightly controlled pipeline with multiple checkpoints, very different from standard manufacturing. Every stage, from material sourcing to final packaging, must be pre-approved. A manufacturer experienced in this field has systematic procedures to manage this, ensuring no step is missed that could lead to a batch rejection or legal issue. What does this end-to-end, compliant process typically involve?

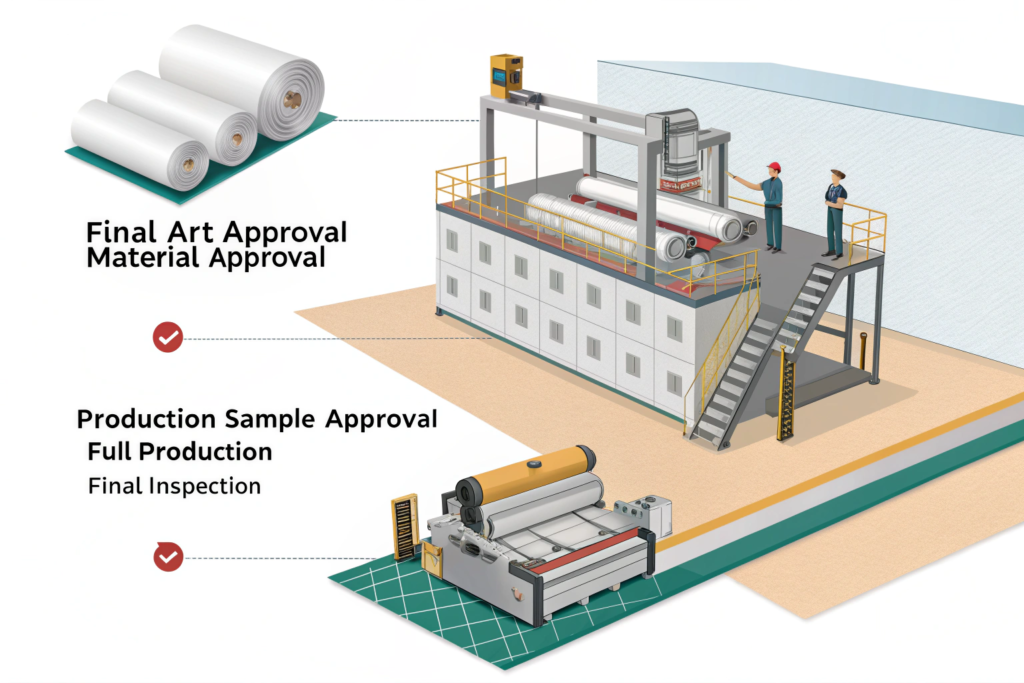

It's a multi-stage workflow with clear gates: Final Art Approval > Material Approval > Production Sample Approval > Full Production > Final Inspection. After the design is approved, the factory must submit samples of the actual fabrics, plastics, or metals for approval to ensure they meet quality and safety standards. Next, a golden sample from the production line is sent for final sign-off before mass production begins. Throughout manufacturing, the factory's quality control team must conduct checks against the approved sample, not just general standards. Finally, the licensor often requires shipment samples to be provided.

What are the Key Compliance Checkpoints During Production?

To ensure consistency, a reliable manufacturer will establish internal checkpoints that mirror the licensor's requirements:

| Checkpoint Stage | Focus of Compliance | Potential Risk if Failed |

|---|---|---|

| Raw Material Incoming | Verifying approved material suppliers & safety certificates (e.g., for cups or children's items). | Use of unapproved or substandard materials. |

| In-Line Production | Monitoring print clarity, embroidery accuracy, and color matching against the golden sample. | Deviations from the approved character artwork. |

| Pre-Shipment Inspection | Conducting a rigorous AQL inspection on finished goods for defects, labeling, and packaging accuracy. | Shipping non-compliant or poor-quality goods. |

| Documentation Finalization | Preparing accurate commercial invoices and packing lists with correct royalty declarations. | Customs delays or licensing audit failures. |

This structured approach, as seen in factories with strong QC teams, turns subjective quality checks into objective compliance verifications.

How Do Licensed Manufacturers Handle Logistics and Royalty Reporting?

The responsibility often extends beyond the factory gate. Experienced licensed manufacturers assist with logistics, ensuring shipping marks and documentation are correct. More importantly, they play a crucial role in royalty reporting. They typically provide detailed production reports—number of units produced, dates, and SKUs—which you need to submit to the licensor for royalty calculations. Some may even handle royalty payments on your behalf as part of their service. Understanding these obligations is part of the product promotion and licensed promotion plans that full-service partners offer. Choosing a partner like Shanghai Fumao Clothing, with experience in complex customs clearance and systematic documentation, ensures this back-end process is smooth, transparent, and secure, fully addressing the pain points of tariff costs and administrative burdens.

How to Evaluate Costs and Manage Risks with Licensed Suppliers?

The financial model for licensed merchandise is fundamentally different. The price you pay is not just for manufacturing; it includes the royalty fee owed to the IP owner, which can range from 5% to 15% or more of the wholesale price. Therefore, when evaluating suppliers, you must look for complete cost transparency and a partnership approach to value engineering—finding ways to optimize production costs without compromising the licensed product's integrity or appeal. How can you effectively budget and manage the financial risks involved?

Start by demanding a detailed, itemized quote. A professional supplier will break down the cost into: 1) Royalty Fee (often a separate line item), 2) Material Cost, 3) Labor & Production Cost, 4) Tooling/Mold Cost (if applicable), and 5) Packaging Cost. This transparency allows you to understand exactly what you are paying for and identify areas for potential adjustment. Furthermore, a savvy manufacturer will help you design for manufacturability—suggesting slight design tweaks that reduce material waste or simplify assembly, thus lowering the production cost portion without affecting the product's marketability. This collaborative cost management is key to maintaining healthy margins.

What are the Common Hidden Costs in Licensed Manufacturing?

Beyond the obvious, several costs can surprise new entrants. Be sure to discuss:

-

Approval and Sample Fees: Some licensors or agents charge fees for each artwork or sample submission.

-

Minimum Guarantee (MG): Most licenses require you to guarantee a minimum amount of royalty payments per year, regardless of sales.

-

Marketing or Fund Contributions: Licensors may require a contribution to a central marketing fund for the property.

-

Late Payment Penalties: Royalty payments are due on strict schedules with penalties for delays.

A trustworthy supplier will guide you through these potential financial obligations. Platforms like INABOOTH, which connect IP owners with users, aim to make licensing contracts more transparent and easier to manage, highlighting the industry's move toward clearer structures.

How Can You Mitigate Financial and Legal Risks?

Risk mitigation starts with choosing the right partner. Work with manufacturers who have product liability insurance, which is a common requirement from licensors to protect all parties. Ensure your contract with the factory includes clear clauses on intellectual property indemnification, holding them responsible if their actions cause an IP infringement. To manage cash flow, discuss flexible payment methods aligned with production milestones. Most importantly, build a relationship with a supplier that communicates proactively about any production issues that could affect cost or timeline, allowing for joint problem-solving. This level of professional customer energy and reliability is what turns a transactional supplier into a long-term strategic asset, safeguarding your investment in the high-stakes world of licensed merchandise.

Conclusion

Finding the right supplier for licensed character merchandise is a detailed process that prioritizes legal compliance, specialized design expertise, and meticulous production management over simple cost comparisons. It requires partnering with manufacturers who are not just producers but informed guides in the complex ecosystem of intellectual property. By focusing on suppliers with proven authorization channels, in-house design teams skilled in style guide navigation, and robust systems for compliance and royalty management, you transform a high-risk venture into a streamlined and profitable product line.

This approach ensures that every product you bring to market upholds the value of the character brand, meets the expectations of passionate fans, and stands up to the rigorous audits of licensors. It turns the challenges of licensing—often seen as barriers—into a structured framework for creating standout, desirable accessories.

If you are looking for a manufacturing partner that combines expertise in quality accessory production with an understanding of the precise demands of licensed merchandise for your next line of character-themed hair bands, scarves, hats, or bags, we invite you to connect with us. Let's discuss how we can help you navigate this exciting market with confidence. You can reach out directly to our Business Director Elaine at elaine\@fumaoclothing.com to start the conversation.