For fashion accessory brands sourcing from China, ensuring product durability is key to maintaining brand reputation and customer satisfaction. When it comes to umbrellas, wind resistance is often the top concern. The answer isn't about finding a single "unbreakable" part, but about building a system where quality materials, smart design, and verified performance work together. From a manufacturer's perspective, here is how to ensure your umbrella orders are truly windproof.

To ensure your umbrellas are windproof, you must adopt a three-part strategy: specify high-performance frame and canopy materials proven for strength and flexibility, incorporate intelligent design features that manage wind forces, and demand that your manufacturer conducts and verifies standardized wind resistance tests before shipping. This comprehensive approach moves beyond guesswork to deliver reliable, high-quality products that protect your brand.

Let's break down this strategy into actionable steps, from the factory floor to final quality inspection.

What Are the Best Materials for a Windproof Frame and Canopy?

The battle against the wind is won or lost in the choice of materials. The frame must balance incredible strength with necessary flexibility, while the canopy fabric needs to be tough enough not to tear under pressure. Compromising on either will result in a product that fails in the field.

For the frame, the industry leaders are fiberglass ribs and carbon fiber. Fiberglass is the benchmark, prized for its excellent balance of strength, flexibility, and cost-effectiveness. It can bend significantly under gusty force and snap back to its original shape without deforming. Carbon fiber is the premium choice, offering even greater strength-to-weight ratio and corrosion resistance, though at a higher cost. For the central shaft, reinforced aluminum or steel provides the backbone. For the canopy, high-density fabrics are key. Polyester is the durable workhorse, known for its tear resistance and ability to handle high winds, especially in higher denier (D) counts like 200D or 300D which indicate a tighter, stronger weave. Advanced materials like TPU (Thermoplastic Polyurethane) laminated onto fabric offer exceptional waterproofing and wind resistance due to their high tensile strength and flexibility.

Why is Flexibility as Important as Strength in a Frame?

A completely rigid frame will snap. A windproof frame must give in order to live. This is where the science of materials is critical. Fiberglass composites are engineered to have a high modulus of elasticity. In practical terms, this means they can absorb the kinetic energy of a strong gust by flexing, distributing the stress along the entire rib, rather than concentrating it at a joint where it would break. Think of it like a tree branch bending in a storm versus a rigid metal rod that snaps. When the wind subsides, the quality fiberglass will return to its original shape. This property makes it far superior to cheaper, brittle aluminum or steel ribs for standard windproof umbrellas. For ultra-premium lines, carbon fiber takes this principle further, offering even greater resilience with less weight. When sourcing, explicitly ask your factory for frame material specifications and request a manual flex test on samples to feel this property firsthand.

How Does Canopy Fabric Denier and Weave Affect Wind Resistance?

The canopy is the sail catching the wind; its construction directly impacts pressure on the frame. The fabric denier (D) is a unit of measurement for the linear mass density of fibers. A higher denier number generally means thicker, stronger yarns and a heavier, more robust fabric. For windproof umbrellas, a canopy made from 190T or 210T polyester with a 200D+ rating is a good starting point for durability. However, denier isn't everything. The weave density (indicated by the "T" or thread count) and the weave pattern (e.g., plain, twill) are equally important. A tight, high-count twill weave, like the 150D x 300D 1/3 twill mentioned in supplier specifications, creates a dense, stable surface that is highly resistant to tearing and deformation under load. During development, you can discuss these technical specifications with your manufacturer to find the optimal balance of weight, hand-feel, and strength for your target market and price point.

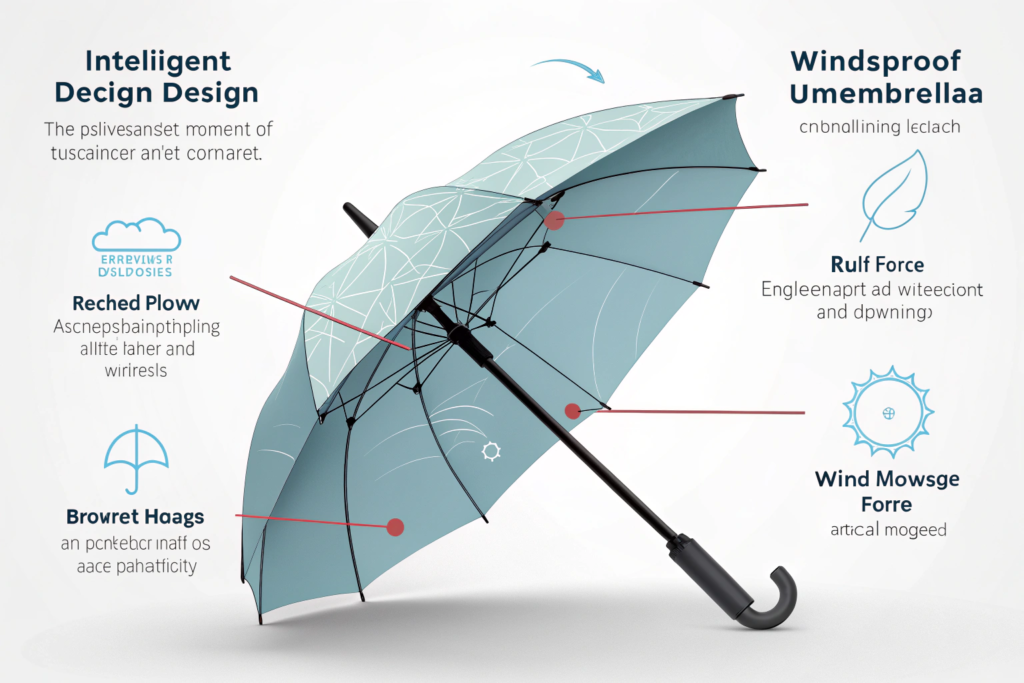

What Design Features Truly Enhance Wind Resistance?

Superior materials alone are not enough. Intelligent design is what leverages those materials to actively defeat the wind. The best windproof umbrellas incorporate specific engineering features that allow wind to pass through or be managed, reducing the uplift force that causes inversion and breakage.

The most critical windproof design features are a double-canopy (vented) construction and reinforced, flexible joints. A double canopy features a top layer and a separated lower layer with vents in between. These vents allow wind to flow through the umbrella rather than getting trapped underneath and pushing it inside out. Additionally, reinforced joints where the ribs meet the stretchers and the shaft are often strengthened with extra metal or plastic caps and designed to allow a degree of pivoting movement, preventing stress fractures.

How Does a Vented Canopy System Work?

A vented canopy is the single most effective design intervention for wind resistance. It works on the principle of pressure equalization. In a traditional solid canopy, wind hits the fabric and creates a high-pressure zone on the windward side while generating lift (like an airplane wing) on the leeward side. This combination of push and lift easily inverts the umbrella. A double-vented canopy disrupts this. The vents, typically located near the top of the umbrella, act as release valves. When wind hits, a portion of it is channeled up and out through these vents, significantly reducing the internal pressure and lift forces. For your product line, you can specify the number and size of vents. Larger or multiple vents offer greater wind relief but may slightly reduce rain coverage. This is a key point to test during the sampling phase with your manufacturer.

Why are Joint and Rib Tip Reinforcements Non-Negotiable?

Stress concentrates at connection points. Therefore, the design and construction of every joint in the umbrella frame must be scrutinized. First, the tips of the ribs that hold the outer edge of the canopy should be rounded or capped, not sharp. This prevents the fabric from tearing during strong flexing. Second, the pivotal joints where stretchers connect to the ribs and the central hub should use durable metal or high-impact plastic connectors rather than simple plastic or thin wire. Some advanced designs use a "flexible arch" construction or independent tension systems that allow ribs to move more independently, preventing a single point of failure. When evaluating a factory like Shanghai Fumao Clothing, ask to see their engineering drawings or samples of these key joints. A manufacturer focused on quality will have robust solutions here, often backed by finite element analysis during design to simulate stress points, as suggested by testing standards.

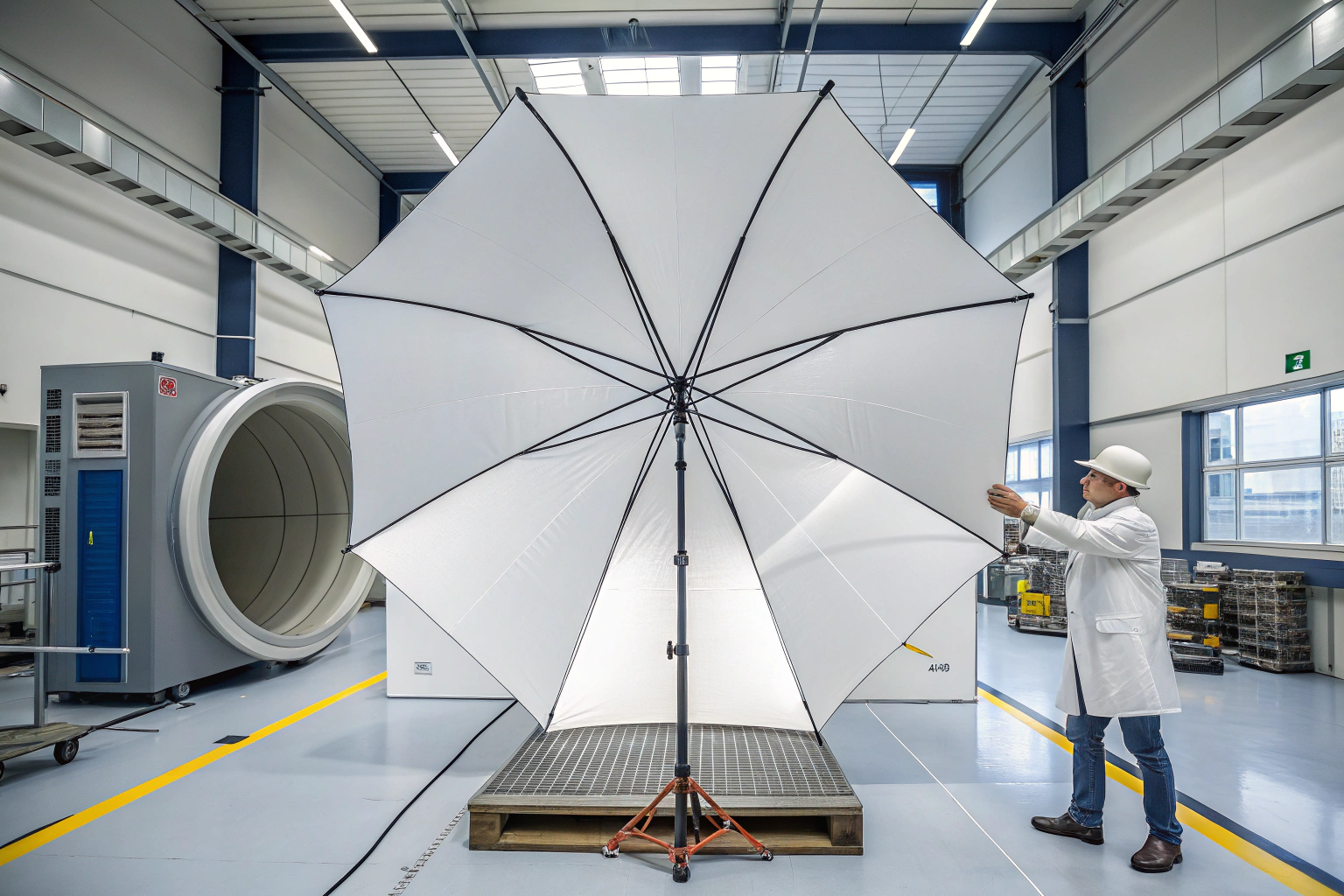

How Can You Verify Windproof Performance with Testing?

Trust, but verify. For a business buyer, accepting a manufacturer's claim of "windproof" is a significant risk. The only way to have genuine confidence and provide accurate marketing claims to your end-customers is to insist on objective, standardized testing. This shifts quality assurance from a subjective promise to a measurable specification.

You should require your manufacturer to conduct testing according to recognized national or international standards. The two key standards are China's GB/T 31895-2015 "Umbrellas—Test method of wind resistance" and the international ASTM F3512-21 "Standard Test Method for Evaluating Wind Safety and Durability of Market Umbrellas". These standards provide scientific, repeatable methods to rate an umbrella's performance. The ASTM F3512-21 standard is particularly comprehensive, outlining two key procedures: Procedure A tests structural integrity against a uniform wind force (a safety test), and Procedure B tests durability under sustained high winds. The results are then correlated to the Beaufort Wind Force Scale, giving you a clear, communicable rating (e.g., "Withstands Force 8 Gale conditions").

What is the Difference Between a "Safety" and a "Durability" Wind Test?

Understanding the test protocols helps you know what you're buying. As per ASTM F3512-21, the tests serve different purposes:

-

Procedure A (Safety Test): This is a pass/fail test for structural strength. The umbrella is subjected to progressively higher wind speeds in a wind tunnel until it fails (e.g., frame breaks, joint separates). The maximum speed before failure determines its safety rating. This tells you the ultimate breaking point.

-

Procedure B (Durability Test): This evaluates long-term resilience. The umbrella is subjected to a sustained, high wind speed (e.g., corresponding to a Beaufort Force 7) for an extended period. It is then inspected for fatigue, deformation, or compromised function. This tells you if the umbrella will remain reliable through many storms, not just one gust.

For your orders, you can specify which test standard must be met and request a copy of the test report from an accredited lab as part of your pre-shipment quality control process.

How Should You Implement Testing in Your Sourcing Workflow?

Make testing a formal checkpoint. During product development, require your manufacturer to provide third-party test reports for the specific umbrella model you are sourcing. For high-volume or high-value orders, consider commissioning an independent inspection company to witness a batch test at the factory or to pull random samples for testing. You can also build the test requirement directly into your purchase agreement. For example: "Product must comply with the safety requirements of GB/T 31895-2015, sustaining wind speeds of XX m/s without permanent deformation or failure. Certificate of compliance from a CNAS-accredited lab required." This formalizes the expectation and gives you contractual recourse if the shipped goods do not meet spec. A reputable manufacturer will be transparent and supportive of this due diligence.

What Should Your Factory Audit Checklist Include for Windproof Umbrellas?

Your relationship with the factory is your primary quality control mechanism. Before placing a large order, due diligence on their capabilities is essential. An audit goes beyond looking at a shiny sample; it investigates the processes, expertise, and quality systems that ensure consistency across 10,000 units.

An effective factory audit for windproof umbrellas should verify material sourcing and storage, in-house testing capabilities (or qualified lab partnerships), and assembly line process control. You need to confirm that the fiberglass they use matches the spec sheet, that canopy fabric rolls are stored properly to avoid degradation, and that workers on the line are trained to spot defects in frame joints and stitching.

How to Assess a Factory's Technical Expertise and Quality Mindset?

Engage their engineering and quality teams in conversation. Ask specific questions:

-

"Can you explain the fatigue resistance of the fiberglass you use?"

-

"What is your stitch-per-inch specification for the canopy seams, and how do you monitor it?"

-

"How do you perform in-line stress tests on finished umbrellas?"

-

"Can you show me your quality control records for rib flex testing?"\

A factory with deep expertise, like Shanghai Fumao Clothing, will have ready answers and documented procedures. They should also be proactive in discussing potential failure points and their solutions. Ask to see their internal testing setup. Even if they use an external lab for formal certification, they should have simple jigs to test opening/closing smoothness, joint rigidity, and canopy attachment strength on a sampling basis.

What are the Critical On-Line Production Checkpoints?

During the walk-through, observe these key stages:

-

Frame Assembly: Watch how ribs are connected to the hub. Is there a secure metal cap or a flimsy plastic one? Is adhesive used correctly?

-

Canopy Stitching: Check the sewing stations. Seams should be straight, tight, and without loose threads. Double-stitching at high-stress points (like where ribs attach to the canopy) is a sign of good quality.

-

Final Assembly and Inspection: See if there is a dedicated inspection station where every umbrella is opened, closed, and checked for alignment, smooth operation, and visual defects. Do inspectors have clear checklists?

-

Packaging: Ensure the packaging protects the product. Umbrellas crushed in transit can have pre-stressed frames.

Finally, review their corrective action process. What happens when a defect is found? A systematic factory will have a process to isolate the issue, find the root cause (e.g., a bad batch of connectors), and rectify it across production.

Conclusion

Ensuring your umbrellas are windproof is a deliberate process that integrates material science, intelligent design, and rigorous verification. It begins with specifying performance-driven components like fiberglass frames and high-density polyester canopies, enhanced by vented designs and reinforced joints. This foundation must then be validated through standardized wind resistance testing, such as GB/T 31895 or ASTM F3512, to translate engineering into a trustworthy performance rating. Ultimately, partnering with a manufacturer that possesses the technical expertise, quality control systems, and transparency to execute this process consistently is the final, critical step to safeguarding your brand and delighting your customers.

By adopting this comprehensive strategy—from precise material selection to factory-floor auditing—you transform windproofing from a marketing buzzword into a reliable product attribute. This builds customer loyalty, reduces returns, and strengthens your position in the competitive accessories market.

If you are looking for a manufacturing partner with the expertise to develop, test, and produce truly windproof umbrellas for your brand, we have the technical capabilities and quality systems in place. Contact our Business Director Elaine at elaine\@fumaoclothing.com to discuss how we can build a durable and successful product line together.