Has this ever happened to you? You're planning your next production run, your budget is set, and then an email lands in your inbox from your supplier: "Important Update: Price Adjustment." Your heart sinks. An unexpected price increase can feel like a punch to the gut, throwing your entire season's financial plan into chaos. Your first instinct might be anger or panic.

So, how should you handle an unexpected price increase? The key is to pause, resist the urge to react emotionally, and instead initiate a calm, strategic conversation with your supplier to understand the reasons behind the increase and collaboratively explore solutions. As the owner of Shanghai Fumao Clothing, I can tell you that when we have to raise prices, it's due to real-world cost pressures that are often outside our control. The brands who navigate these situations most successfully are the ones who treat us as partners, not adversaries.

Will simply demanding a lower price work? Rarely. Will switching suppliers instantly solve the problem? It's risky. A better approach is to engage in a professional negotiation aimed at a win-win outcome. Let's walk through the four steps you should take when you face this challenging situation.

Why Must You First Understand the "Why"?

Before you can formulate a response, don't you first need to understand the root cause of the increase? A price hike from a reputable supplier is not an arbitrary decision to make more profit off you. It's almost always a reaction to a tangible increase in their own costs. Your first step should be to politely and professionally ask for a clear explanation.

Is it a spike in raw material costs? A change in labor laws? A surge in shipping rates? Understanding the specific driver is crucial because it determines which solutions are possible. For example, if the cost of leather has gone up, we can't do much about that specific material, but we might be able to explore alternative materials. If it's a labor cost issue, perhaps we can look at simplifying the design to reduce the man-hours required.

Isn't a clear diagnosis the first step to finding a cure? A good partner will be transparent with you. This is a test of your relationship and their professionalism, which is something you should be vetting from your first communication with them.

What Are the Most Common Reasons for Price Increases?

From my side of the table, what are the usual culprits?

- Raw Material Costs: This is the most common reason. The market price for cotton, leather, polyester, or metals can fluctuate wildly due to global supply and demand. A drought in a cotton-producing region or a new tariff can have a direct impact.

- Labor Costs: Governments may increase the minimum wage, or a shortage of skilled workers can drive up labor costs. This is a real, unavoidable expense for the factory.

- Currency Fluctuation: If the currency in the manufacturing country (like the Chinese Yuan - RMB) strengthens against your currency (like the US Dollar), the factory needs more of your dollars to cover their local costs.

- Energy and Utility Costs: The cost of electricity to run the machinery and light the factory can increase, impacting overheads.

- Regulatory Changes: New environmental or safety regulations might require us to invest in new equipment or use more expensive, compliant chemicals, adding to the cost.

How Should You Phrase Your Request for Information?

How do you ask for this without sounding accusatory? Try a collaborative tone. For example: "Thank you for the update. To help me understand the new pricing and explain it to my team, could you please share some insight into which specific costs (e.g., materials, labor, etc.) have driven this change? We value our partnership and would like to work together to find the best path forward." This opens the door for a productive conversation.

Can You Collaboratively Explore Cost-Saving Modifications?

Once you understand the "why," your next step is to work with your supplier to see if you can offset the increase by making smart modifications to the product. This is called value engineering. It's a creative process where you and your factory's technical team act as partners to pull costs out of the product without destroying its quality or appeal.

This is often the most fruitful area for negotiation. A good supplier has deep knowledge of materials and production methods. They might be able to suggest a slightly different but visually identical material that costs less, or a small change in construction that makes the product much faster and cheaper to produce.

Are you open to being flexible? A willingness to explore these options shows your supplier that you are a pragmatic and valued partner. This is far more effective than simply saying "no" to the price increase.

What are Common Value Engineering Opportunities?

Where can you usually find savings?

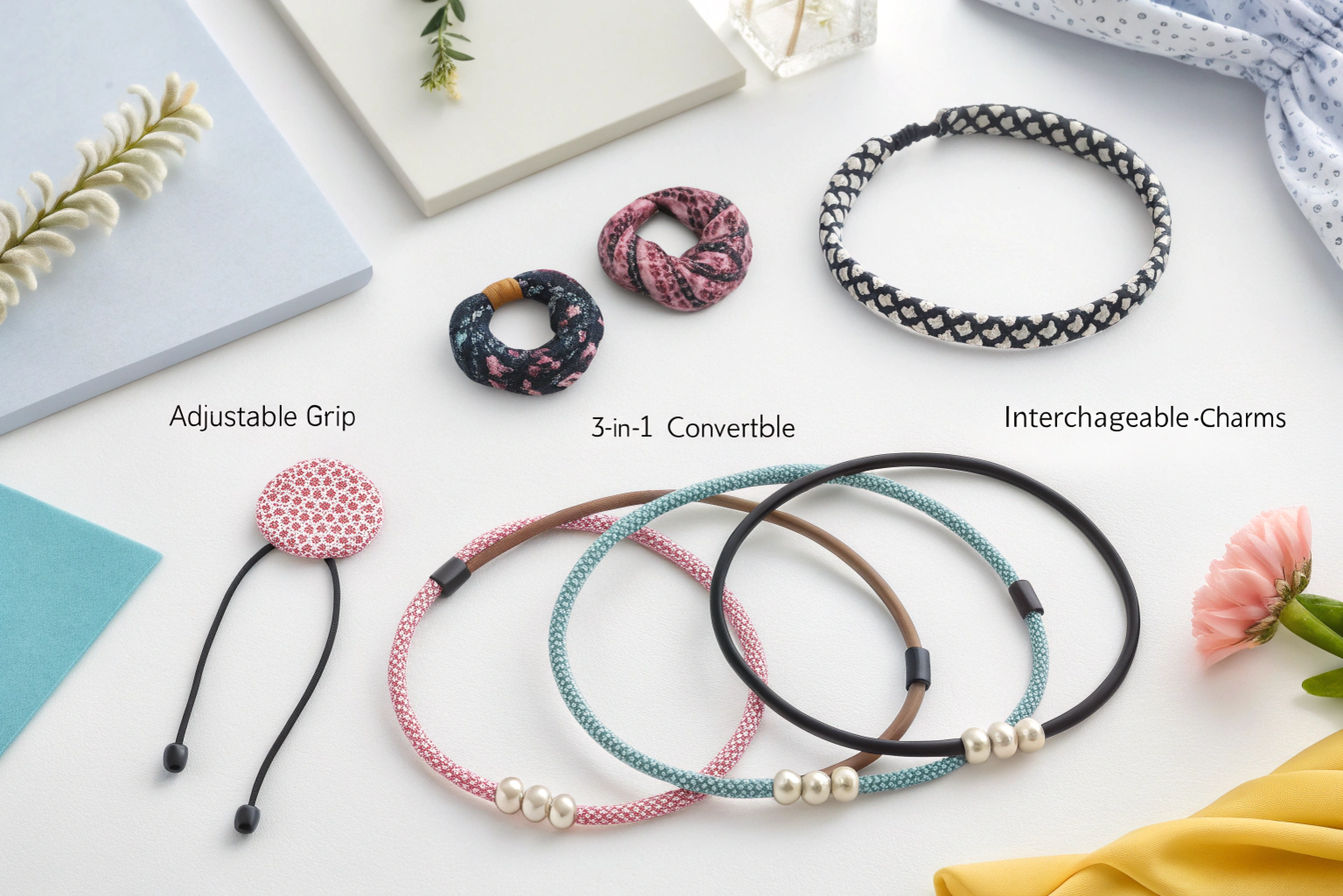

- Material Substitution: If the price of genuine leather has spiked, could you use a high-quality PU or a different grade of leather? If a specific brand of zipper is expensive, is there a comparable, high-quality alternative?

- Construction Simplification: Does your handbag design have an overly complex internal pocket system that could be simplified? Can the number of stitches per inch be slightly reduced without affecting durability? Does the product require a lot of hand-finishing that could be minimized? This is where fast sample development is key, as you can quickly get a revised sample to approve.

- Packaging: Is your product coming in an expensive, multi-part gift box? Could you switch to a simpler, lighter box or a high-quality branded dust bag to save on both cost and shipping weight?

How Can You Leverage Your Order Volume?

Can you use your order size as a negotiating tool? Yes. Ask your supplier: "At what order quantity would we be able to get a better price?" Sometimes, increasing your order volume for a specific style can allow the factory to achieve better economies of scale, purchase raw materials at a lower price, and pass some of those savings back to you. This is a classic win-win negotiation tactic.

Should You Re-Evaluate Your Own Pricing and Strategy?

While negotiating with your supplier is important, you must also look inward at your own business. Sometimes, a cost increase from your factory cannot be fully avoided. In a global economy with inflation, it's a reality of doing business. This is a moment to strategically re-evaluate your own pricing.

Have you raised your retail prices in the last year? Are your profit margins already razor-thin, or do you have some room to absorb the increase? Many brand owners are afraid to raise their prices, fearing they will lose customers. However, small, strategic price increases are a normal and necessary part of running a sustainable business.

Isn't it possible that your product is currently underpriced for the value it provides? This could be the perfect opportunity to adjust.

How Do You Justify a Price Increase to Your Customers?

How can you raise prices without alienating your base? The key is to communicate the value. You don't necessarily need to announce the price increase. Instead, you can use this moment to reinforce your brand's commitment to quality. Refresh your product photography, write more compelling descriptions focusing on the quality materials and craftsmanship, and continue to build your brand story. When customers perceive high value, they are less sensitive to small price changes.

Can You Absorb Some of the Cost?

What if you decide not to raise your retail price? You need to analyze your Gross Profit Margin. If your margin is healthy (e.g., 60-70%), you may decide to absorb the small cost increase, resulting in a slightly lower but still healthy margin. This is a strategic choice to maintain your current market position. However, if your margins are already low, absorbing the increase could make the product unprofitable, which is not a sustainable long-term strategy. This is why planning your budget with healthy margin targets is so crucial from the start.

When is it Time to Consider a New Supplier?

What if the price increase is substantial and the supplier is unwilling to collaborate on solutions? What if this is part of a pattern of unreliable behavior? In this case, it may be time to start exploring alternative suppliers.

However, you should approach this step with extreme caution. Finding, vetting, and onboarding a new supplier is a long, expensive, and risky process. The "cheaper" price from a new, unknown factory might come with the hidden costs of lower quality, poor communication, and missed deadlines. Your current supplier has invaluable knowledge of your products and standards.

Should you switch suppliers over a single, small price increase? In my experience, it's rarely worth the risk. This option should be reserved for situations where the increase is truly unsustainable or the partnership has fundamentally broken down.

What is the True Cost of Switching?

Before you jump ship, what should you calculate?

- New Development Costs: You will have to pay for new samples and potentially new molds with the new supplier.

- Time Cost: The entire sample development process will start from scratch, which could take months and cause you to miss a season.

- Quality Risk: A new supplier does not know your quality standards. The first production run with a new partner is always the riskiest.

- Loss of Partnership: You lose the relationship and trust you've built with your current partner, who likely has helped you solve problems in the past.

How Should You Explore New Options Safely?

What's the smart way to do this? Don't fire your current supplier. Instead, start a small, parallel "test project" with a potential new supplier. Give them a single, non-critical product to develop and produce. This allows you to vet their quality, communication, and reliability on a small scale with low risk. This gives you a "Plan B" for the future without burning your most important bridge.

Conclusion

So, how should you handle an unexpected price increase? Should you panic or get angry? No. You should see it as a critical business challenge that requires a calm, strategic, and professional response.

The best path forward is almost always through partnership. Start by understanding the reasons, then collaborate on creative solutions, and be willing to re-evaluate your own pricing. By treating your supplier as a partner in solving a shared problem, you can often arrive at a solution that works for both of you and strengthens your relationship for the long term. Only after exhausting these options should you take on the significant risk of finding a new partner.

We believe that transparency is the key to navigating these challenges. A good partnership is strong enough to withstand tough conversations about cost. If you're looking for a supplier who believes in open communication and collaborative problem-solving, we would be honored to work with you. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com.