As a professional buyer like Ron, you know that when it comes to winter gloves, there's one promise that matters above all others: warmth. A customer who buys a "winter" glove only to get cold hands is a customer you'll lose forever. They won't blame the weather; they'll blame your brand. You need to source gloves that don't just look warm but can verifiably perform in cold conditions. But "warmth" is subjective. How do you turn that feeling into a measurable, objective standard for your bulk production?

To ensure glove warmth meets winter standards, you must move beyond subjective feel and adopt a scientific, data-driven approach. This involves specifying the right type and weight of insulation (like 3M Thinsulate™), understanding the CLO value as a measure of thermal resistance, and implementing a consistent quality control process to verify the insulation in every batch. It's about engineering warmth, not just hoping for it.

This is a conversation I have with every client who wants to develop a serious winter accessories program. It's easy to make a glove that looks bulky; it's much harder to make one that is genuinely warm without being clumsy. At Shanghai Fumao Clothing, we've invested in the materials science and quality control systems to do just that. Let me demystify the process and show you how to source winter gloves with confidence.

What Is the Most Important Component for Glove Warmth?

Many factors contribute to warmth, but one component does 90% of the work. If you get this part right, you're most of the way there.

The most important component for glove warmth is the insulation material trapped between the outer shell and the inner lining. The outer shell blocks wind and water, but it's the insulation's job to trap air, creating a thermal barrier that stops your body heat from escaping. The type and amount of insulation are the most critical specifications in your tech pack.

This is the first thing we specify. A tech pack that just says "add insulation" is a recipe for failure. We need to be specific. Are we using a branded insulation like 3M Thinsulate™, or a high-quality generic polyester fill? What is the weight? A glove for a cool autumn day might use 40 grams of insulation, while a glove for serious winter conditions will need 100 grams or more. This decision is the absolute foundation of the glove's performance and is a prerequisite for understanding how warmth is measured.

Why is 3M™ Thinsulate™ the industry benchmark?

3M™ Thinsulate™ Insulation is a globally recognized brand of synthetic insulation. It's known for being "warm without bulk" because its microfibers are far finer than traditional polyester, allowing them to trap more air in less space. Specifying a branded insulation like Thinsulate™ provides instant credibility and a performance guarantee, though it comes at a higher cost than generic fills.

How is insulation weight measured?

Insulation is measured in grams per square meter (GSM). A higher GSM number means a thicker, warmer insulation.

- 40g: Good for cool weather, high-activity gloves where dexterity is key.

- 70g-100g: The sweet spot for most standard winter gloves for daily wear.

- 150g and above: For extreme cold, arctic conditions, or less active use where maximum warmth is needed.

How Is Glove Warmth Scientifically Measured?

"Feels warm" is a marketing opinion. "Has a CLO value of 1.5" is a scientific fact. To ensure consistent quality, you need to speak the language of data.

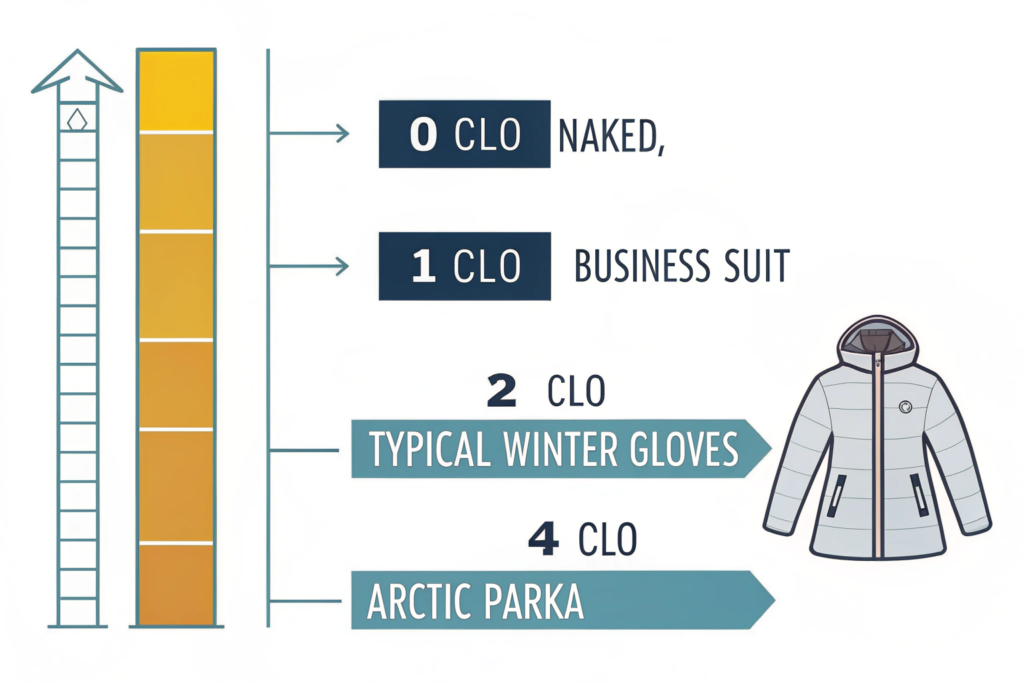

Glove warmth is scientifically measured using a value called "CLO" (pronounced "kloh"), which quantifies the thermal resistance of a garment. One CLO is the amount of insulation needed to keep a resting person comfortable in a room at 21°C (70°F). The higher the CLO value, the warmer the glove.

While we don't conduct CLO testing on every single glove, we use it during the development phase to benchmark our materials. We can send a sample glove to a third-party lab to get its CLO rating. This gives us a performance baseline. For example, we know from experience that a glove with 100 grams of a specific type of insulation will achieve a CLO value of around 2.0. We can then use this data to build the tech pack and ensure the bulk production uses the exact same materials to achieve the same performance, which is verified through our QC process.

Where did the CLO unit come from?

The CLO unit was developed by the US Army during World War II to standardize clothing insulation. It's a fundamental concept in textile science and thermal comfort. You can find detailed explanations from textile science departments at universities like Cornell University or through standards organizations.

What's a good CLO value for winter gloves?

- 1.0 - 1.5 CLO: Suitable for general cool-weather use.

- 1.5 - 2.5 CLO: A good range for standard winter gloves intended for daily commuting and general outdoor activities.

- 2.5+ CLO: This is entering the territory of high-performance or expedition-weight gloves for serious cold.

How Do You Verify the Insulation in Bulk Production?

You've specified 100g Thinsulate™ in your tech pack. How do you know the factory didn't secretly use a cheaper, 80g generic fill to save money? This is where trust, but verify, comes in.

You verify the insulation during bulk production through a multi-step QC process: demanding a Transaction Certificate for branded insulation, performing random spot-checks by cutting open sample gloves from the production line, and weighing the insulation to ensure it matches the specification.

This is a standard procedure at Shanghai Fumao Clothing. First, if you've specified 3M™ Thinsulate™, we provide you with the TC from 3M, proving we purchased the genuine material for your order. Second, during production, our on-site QC inspector will randomly select several gloves, cut them open, and physically inspect the insulation. They will compare it to the approved pre-production sample and can even weigh the material to ensure the GSM is correct. This rigorous, physical verification is the only way to guarantee that what's on the inside of the glove matches what's on the tech pack. This process is critical for ensuring the final product is fit for purpose.

What is a "destructive test"?

This is any test that involves destroying the product to inspect it, like cutting open a glove. While the tested glove cannot be sold, this process is essential for ensuring the quality of the other 9,999 gloves in the order. It's a standard part of any robust quality assurance program.

Can you use a third-party inspector?

Absolutely. For large orders or for new clients who want extra peace of mind, we welcome them to hire a third-party inspection service like QIMA or SGS. Their inspectors can come to our factory and perform these same checks, providing an unbiased report and complete transparency.

How Do You Match Warmth Level to the Intended Use?

Not all winter gloves are created equal. A glove designed for skiing has different needs than one designed for running or driving. How do you ensure the warmth level is appropriate for the end-use?

You match the warmth level to the intended use by creating a "good, better, best" strategy within your collection, using different insulation weights and features for different activities. This allows you to offer the right product to the right customer, preventing issues like a runner's hands getting too sweaty or a commuter's hands getting cold.

This is a product strategy conversation we have with our clients. We might suggest a three-tiered glove program:

- "Good" (Activity/Running): A lightweight, 40g insulated glove with high dexterity and a touchscreen-compatible fingertip.

- "Better" (Daily Wear/Commuting): A 100g insulated glove with a durable shell and a comfortable fleece lining. This is your volume driver.

- "Best" (Extreme Cold/Low Activity): A 150g insulated glove, possibly with a waterproof membrane and a longer cuff for maximum protection.

By clearly defining the purpose of each glove, you can make smarter design and material choices, ensuring every product in your collection is a winner.

What is a waterproof/breathable membrane?

This is a special layer (often made of ePTFE, the material in GORE-TEX) that can be inserted between the insulation and the outer shell. It has microscopic pores that are too small for water droplets to pass through from the outside, but large enough for water vapor (sweat) to escape from the inside. It's a premium feature for high-performance gloves.

Why is dexterity important?

Dexterity is the ability to perform tasks with your hands. Thicker insulation reduces dexterity. For activities like driving, using your phone, or running, a less bulky glove is essential, which is why a lower insulation weight is often used for these styles.

Conclusion

Ensuring your gloves meet winter standards is a science, not an art. By moving the conversation from subjective "warmth" to objective data, you can build a better, more reliable product. The key is to partner with a manufacturer who understands this. A partner who can help you specify the right type and weight of insulation, who understands performance metrics like CLO value, and who has a transparent quality control process to verify what's inside the glove. This data-driven approach is how you build a winter glove program that earns customer trust and protects your brand's reputation, season after season.

At Shanghai Fumao Clothing, we are fluent in the science of warmth. We have the material expertise and the rigorous QC systems to ensure that the glove we develop with you is the glove we deliver in bulk—guaranteed.

If you are ready to build a winter glove collection based on performance and trust, let's talk. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com, to get started.