The question of how much it costs to manufacture a leather belt in China is deceptively simple. Quoting a single price is misleading because the final cost is a dynamic equation, not a fixed number. It is shaped by everything from the quality of the leather in your hands to the efficiency of the factory floor. For buyers targeting major supermarkets or fashion brands, understanding this equation is critical to balancing quality, compliance, and profitability.

The true cost of manufacturing leather belts in China is a composite of four key variables: the grade and type of leather, the complexity of design and craftsmanship, the scale of your order, and the logistical path to your warehouse. A basic PU belt can start under $2, while a full-grain leather belt with intricate work can exceed $15 or more at the factory gate. The final landed cost for your market will include additional layers for logistics, duties, and certification.

This guide will dissect each component of the cost structure, providing you with a clear framework to request accurate quotes and make informed sourcing decisions for your specific market segment. Learn more Shanghai Fumao Clothing details page.

How does material choice drive the base cost?

The single most significant cost driver in a leather belt is the material itself. The term "leather" encompasses a vast spectrum of quality, origin, and price. Choosing between genuine leather, top-grain, full-grain, or bonded leather will fundamentally set the price floor and ceiling for your product.

Material costs can account for 40% to 60% of the total manufacturing cost of a leather good. This makes your specification the primary lever for controlling expenses. For example, belts for fast-fashion or value-oriented supermarket lines often use synthetic PU or bonded leather to hit aggressive price points, while mid-tier brands and department stores typically specify top-grain leather for a balance of durability and cost. Luxury or heritage brands insist on full-grain or exotic leathers, where the material itself is the key selling point.

To make an informed choice, you need to understand the trade-offs between the two main categories of materials: genuine leather and its alternatives.

What is the price range for different types of leather?

The hierarchy of leather directly correlates with price:

- PU (Polyurethane) / Synthetic Leather: The most cost-effective option. Prices are very low and stable. A supplier listing on HKTDC shows fashion belts (using top layer leather or PU) at a FOB price range of $1.60 - $2.30. This is typical for high-volume, low-cost segments.

- Genuine Leather: This is a broad term often referring to split leather that has been refinished. It's a real leather but from the lower layers of the hide. It offers a step up in authenticity from PU at a moderate cost.

- Top-Grain Leather: The most common type of quality leather. It has the top layer sanded and refinished to remove imperfections, offering excellent durability and a uniform look. It is the standard for most branded belts.

- Full-Grain Leather: The highest quality, using the full, un-sanded outer layer of the hide. It develops a unique patina over time. Material costs are significantly higher, reflecting the quality and scarcity of flawless hides.

How do alternative materials and hardware affect cost?

Beyond the strap, other components create cost variations:

- Bonded Leather: Made from leather fibers bonded with latex or polyurethane. It is priced slightly above PU but below genuine leather and is common in budget-friendly goods.

- Buckle and Hardware: A simple zinc alloy buckle is inexpensive. Costs rise with material (e.g., polished brass, stainless steel), size, weight, and complexity (e.g., intricate logos, dual-prong designs, magnetic closures). Custom-designed, branded buckles require mold creation, which is a significant one-time tooling cost (often $500-$2,000 per design) amortized over the production run.

- Lining and Stitching: A fabric or leather backer adds cost. Stitch density and thread quality (e.g., bonded nylon vs. standard polyester) also contribute.

What manufacturing processes add the most value and cost?

Once materials are selected, the manufacturing process transforms them into a finished product. The level of craftsmanship, automation, and handwork involved is the second major pillar of cost. A fully automated line pumping out simple webbed belts has a completely different cost structure than a workshop where artisans hand-cut, hand-dye, and hand-stitch each piece.

The choice between mass production and semi-handmade/artisanal production creates the largest cost divergence at this stage. Mass production in large, modern factories leverages economies of scale, specialized machinery (like laser cutters, automatic skivers, and high-speed presses) to keep per-unit labor costs low. Artisanal production relies on skilled labor for operations like hand-bevelling, hand-dyeing, and saddle stitching, which increases time and cost but results in a unique, high-end product.

The cost of manufacturing is not just about the act of assembly; it encompasses the entire journey from raw hide to polished belt. Two critical phases in this journey are where value is added and costs are incurred.

How do cutting, stitching, and finishing steps contribute to cost?

The production process is a series of value-adding steps, each with associated costs:

- Cutting & Skiving: Precision cutting (die-cutting or computer-controlled) minimizes waste. Skiving (thinning the leather at the ends) requires skill. Automated skiving machines are more consistent and faster than manual work.

- Stitching: Machine stitching is standard. Cost increases with stitch-per-inch (SPI) density and complexity (e.g., contrast stitching, double rows). Hand-stitching (e.g., saddle stitch) is a premium feature that drastically increases labor time and cost but offers superior durability and aesthetics.

- Finishing: This includes edge painting (multiple coats, sanding, and polishing), surface treatments (oiling, waxing, polishing), and embossing/debossing (adding textures or logos). A high-gloss, mirror-finished edge takes more steps than a simple painted edge.

Why are dyeing, embossing, and quality control significant cost factors?

- Dyeing: Using aniline or semi-aniline dyes that penetrate the leather is more expensive than surface-level pigment dyes. Hand-applied antiquing or patina effects are labor-intensive and add substantial cost.

- Embossing/Debossing: Adding a brand logo, texture, or pattern requires a custom metal die. While the unit cost addition is small once the die is made, the initial tooling investment is required.

- Quality Control (QC): A factory with a rigorous, multi-stage QC process (checking leather grain, stitching, buckle function, dimensions) will have slightly higher overhead, but this prevents costly rejections and returns. This is a non-negotiable cost for supplying major retailers.

How do order volume and factory efficiency determine unit price?

In manufacturing, scale is everything. The quantity you order is the most powerful lever to pull on the final unit price. This is due to the concepts of economies of scale and Minimum Order Quantity (MOQ). Factories can spread fixed costs (like setting up production lines, creating custom dies, and allocating QC resources) over more units, dramatically reducing the cost per belt.

For large supermarket chains or global brands, the ability to place orders in the tens or hundreds of thousands of units unlocks the lowest possible pricing. For example, an industry report analyzing a leather belt manufacturing project indicated that at a stable operational scale, such a business can achieve significant annual sales revenue. This scale allows for optimized material purchasing and streamlined production. Smaller brands or test orders will face higher per-unit costs but can work with factories that offer lower MOQs, sometimes as low as 500-1,000 pieces for standard designs.

Understanding the factory's operational metrics is key to negotiating a fair price. Two critical concepts govern this relationship.

What is the impact of MOQ and economies of scale on pricing?

- Minimum Order Quantity (MOQ): Factories set MOQs to ensure a run is profitable. A higher MOQ (e.g., 5,000+ units) always commands a lower unit price than a smaller MOQ (e.g., 500 units). The price difference can be 20-40% or more.

- Economies of Scale: As order volume increases, the fixed costs per unit plummet. The cost of setting up the production line, programming machines, and conducting pre-production inspections becomes negligible when divided by 50,000 units versus 5,000 units. Bulk purchasing of leather and hardware also secures material discounts.

How do labor costs and factory overhead factor into the quote?

- Labor Costs: While Chinese labor costs have risen, they remain competitive, especially in inland provinces. Labor-intensive processes (hand-stitching, detailed finishing) are a larger portion of the cost than for fully automated lines. Factories with higher skilled labor may charge more but deliver better quality.

- Factory Overhead & Profit Margin: The quote includes the factory's overhead (rent, management, utilities, equipment depreciation) and their desired profit margin[citation:6]. Modern, well-managed factories with strong compliance records may have slightly higher overhead but offer reliability crucial for major retailers. Their profit margin is typically a percentage added to the total cost.

What hidden costs must be calculated for the final landed cost?

The factory's quoted FOB (Free On Board) price is just the beginning. The landed cost—the total expense to get the belts to your distribution center—includes several critical layers that are often overlooked. Failing to account for these can erode your profit margin entirely. For a buyer like "Ron," who is concerned with tariff costs and logistics timeliness, this calculation is essential.

Key hidden costs include international freight, insurance, import duties and taxes, and the cost of compliance testing. For example, shipping a container from China to the US West Coast can cost several thousand dollars, which must be allocated across the container's contents. Furthermore, the Harmonized System (HS) code for your belts determines the duty rate, which in the US can vary. A recent industry report also highlights that potential shifts in the US tariff framework can introduce significant market volatility and must be considered in cost forecasting.

To avoid financial surprises, you must build a complete cost model that includes two major categories of post-production expenses.

How much should you budget for shipping, insurance, and duties?

- Freight & Insurance: Costs vary by mode (sea vs. air), container load (FCL vs. LCL), fuel prices, and season. Always get multiple freight quotes. Insurance (typically 0.2%-0.5% of cargo value) is a small but necessary cost.

- Import Duties & Taxes: This is a percentage of the declared value of your goods. The rate depends on the product's HS code and the country of import. For the US, leather belts generally have a duty rate. You must calculate this and any local sales/use taxes to know your true cost per unit.

What are the costs for compliance, testing, and packaging?

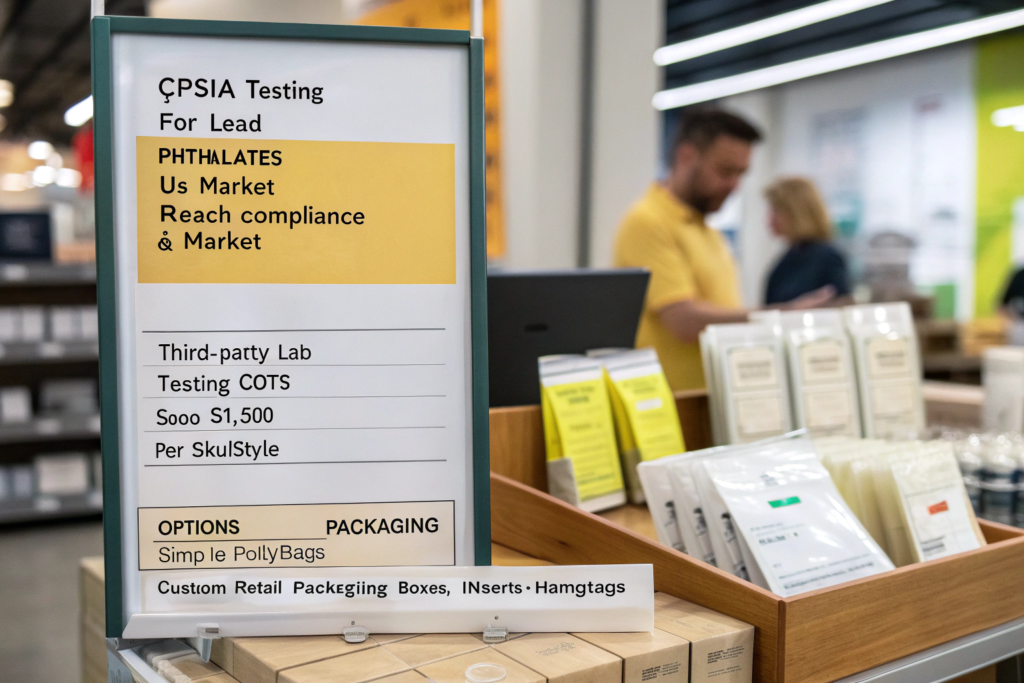

- Compliance & Testing: Selling to major markets requires safety and compliance testing. For the US, this may include CPSIA testing for lead and phthalates (especially if targeting a market with children's products). For the EU, REACH compliance is needed. Third-party lab testing can cost $500-$1,500 per SKU/style, depending on the tests required.

- Packaging: The factory's quote may include a simple polybag. Custom retail packaging (boxes, inserts, hangtags) adds significant cost. Ensure the packaging specifications (size, material, printing) are detailed and priced separately.

Conclusion

Manufacturing leather belts in China is a cost structure, not a single price. It is a composite built on your choices of material grade, which sets the foundation; the complexity of craftsmanship, which adds value and expense; the power of order volume, which leverages economies of scale; and the often-overlooked logistics and compliance layers, which determine the final landed cost. A basic PU belt can start under $2, while a premium full-grain leather belt with custom details can cost $15 or more at the factory gate, before shipping and duties.

The most effective strategy is to approach manufacturers with clear, detailed specifications and request a comprehensive FOB quote and an estimated landed cost breakdown. This transparency allows for accurate budgeting and prevents costly surprises. If you are looking for a manufacturing partner that can provide clear cost structures, from material sourcing to final logistics, for your leather belt program, let's discuss your specific needs. Contact our Business Director, Elaine, at elaine@fumaoclothing.com to explore how we can build a cost-effective and reliable supply chain for your brand.