Selecting the right cut-resistant gloves for a commercial kitchen is a critical safety and operational decision. You need to protect staff from sharp blades and mandolines while ensuring compliance with food safety regulations and maintaining dexterity for intricate tasks. So, which gloves truly offer the necessary balance of protection, hygiene, and practicality for a high-paced kitchen environment? The answer lies in understanding international safety ratings, food-contact compliance, and material technologies designed specifically for food service.

The most suitable cut-resistant gloves for kitchen staff are those rated at least Level C under the EN388:2016 standard or A5-A9 under the ANSI/ISEA 105 standard, are explicitly certified for food contact (FDA or EU compliance), and are made from durable, washable materials like high-performance polyethylene (HPPE) or fiberglass blends. They must also provide adequate dexterity and grip.

A glove that is safe for a construction site isn't automatically safe for a kitchen. Let's dissect the key features that define a professional kitchen-ready cut-resistant glove.

How to Decode Safety Ratings for Kitchen Gloves?

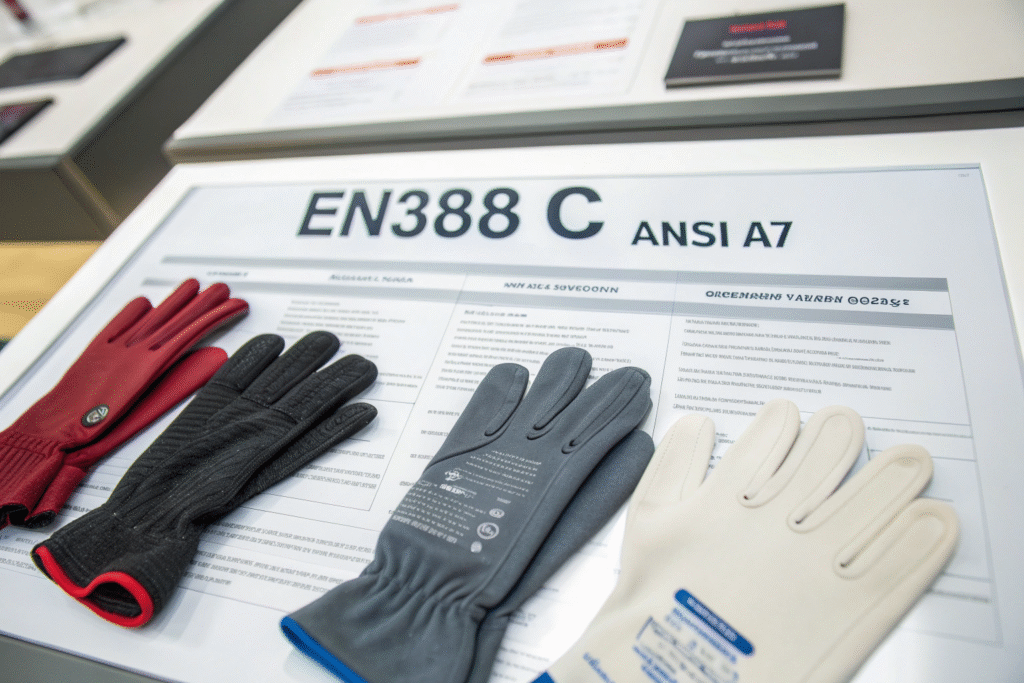

Facing a product page filled with codes like "EN388 C" or "ANSI A7" can be confusing. These ratings are not marketing terms; they are the result of standardized laboratory tests that measure a glove's resistance to cutting. Choosing a glove with an inappropriate rating is a direct safety risk.

For kitchen work, you primarily need to understand two global standards: EN388 (European) and ANSI/ISEA 105 (American). Both use a scale where a higher letter or number indicates greater cut resistance. For handling sharp knives in food prep, a minimum of EN388 Level B or ANSI Level A4 is recommended for general tasks, while deboning meat, breaking down poultry, or shucking shellfish demands Level C/D (EN388) or A5-A9 (ANSI).

Understanding what these tests measure is key to making an informed choice. The ratings are determined by specific, rigorous methods.

What Do EN388 and ANSI Ratings Actually Mean?

The EN388:2016 standard introduced a more realistic test called the TDM (Tomodynamic Cut Test). It uses a reciprocating blade under a fixed load, simulating the action of a knife slip. The result is a letter grade from A (lowest) to F (highest). For kitchen knives, a rating of C or D offers substantial protection for most high-risk tasks.

The ANSI/ISEA 105-2016 standard uses a Coupe Test with a straight blade under increasing load. It gives a number rating from A1 to A9. An A5 to A7 rating is generally considered suitable for handling sharp kitchen knives. It's crucial to note that these scales are not directly equivalent, but they are the primary benchmarks for comparison. As a bulk buyer, specifying the required rating to your supplier is non-negotiable. Manufacturers like shanghaifumaoclothing that produce safety gear understand these specifications and can guide product selection.

Why Is the New TDM Test More Relevant for Kitchens?

The older EN388 test used a circular blade that could become clogged with high-tech fibers, inflating the score. The new TDM test better replicates a sharp knife's cutting action. When evaluating gloves, always look for the EN388:2016 rating, which includes both the old and new scores (e.g., 4541C). The letter at the end is the TDM rating and the one you should prioritize for kitchen safety. A glove boasting only a high score under the old standard may not perform as well against a real chef's knife.

What Defines a Glove That's Safe for Food Contact?

A glove can be incredibly cut-resistant but entirely unsuitable for a kitchen if its materials are not approved for food contact. The risk of fiber fragments, chemical migration, or bacterial growth inside the glove is a serious health hazard. Food safety compliance is not an optional feature; it is a mandatory requirement.

A food-safe cut-resistant glove must be made from materials compliant with FDA Title 21 CFR (for the US market) or EU Regulation (EC) No 1935/2004 (for the European market). These regulations ensure that materials in contact with food do not transfer harmful substances in quantities that could endanger health.

Beyond legal compliance, practical hygiene features define a glove's suitability for daily kitchen use.

Why Are Fiber Safety and Construction Critical?

Some cut-resistant gloves use fiberglass strands for protection. If the construction is poor, these microscopic glass fibers can break and migrate through the glove, contaminating food. Therefore, the best kitchen gloves use engineered yarns like HPPE (e.g., Dyneema® or Spectra®) or aramid fibers (e.g., Kevlar®) or feature a "no-glass" or "fiber-free" design that encapsulates the protective fibers within a coating or a durable polymer matrix.

Look for gloves with a smooth, seamless interior lining. This prevents the inner fibers from shedding onto the skin and, more importantly, into food. It also makes the glove more comfortable to wear for extended periods, increasing the likelihood that staff will use them consistently. For high-volume kitchen suppliers, offering a range with these certified, fiber-safe constructions is a major selling point.

How Do Hygiene Features Like Washability Extend Glove Life?

Kitchen gloves are subjected to heavy soiling. A glove that cannot be thoroughly and repeatedly cleaned is a biohazard and an unnecessary recurring cost. High-quality kitchen cut-resistant gloves are designed for industrial laundering at high temperatures (often 70°C - 85°C).

Key features to look for include:

- Machine Washable & Dryable: Allows for cost-effective, sanitary cleaning.

- Antimicrobial Treatment: Inhibits the growth of odor-causing bacteria and mold inside the glove.

- Liquid-Repellent Coating: Provides a barrier against blood, juices, and oils, making the glove easier to clean and dry.

This durability directly impacts your total cost of ownership. A glove that survives 50+ wash cycles, like some Tilsatec models, offers far better long-term value than a cheaper glove that degrades after five washes.

Which Glove Materials and Designs Offer the Best Kitchen Performance?

With safety and hygiene covered, the final decision comes down to performance: can the staff actually work while wearing them? The ideal glove feels like a second skin, providing protection without sacrificing the tactile sensitivity needed to fillet a fish or julienne a vegetable.

The leading materials for kitchen dexterity are High-Performance Polyethylene (HPPE) and advanced polyurethane (PU) or nitrile coatings. HPPE yarns like Dyneema® offer an excellent strength-to-weight ratio, resulting in thin, flexible, and highly cut-resistant gloves. A PU-dotted or nitrile palm coating enhances grip on wet knives and slippery food surfaces.

The right combination of materials addresses the unique challenges of the kitchen workstation.

Why is HPPE a Top Choice for Kitchen Dexterity?

Gloves made from 100% HPPE or HPPE blends are exceptionally popular in food processing. They are:

- Lightweight & Flexible: Allow for fine motor skills and reduce hand fatigue.

- Highly Cut-Resistant: Provide reliable protection for their thin profile.

- Resistant to Water & Many Chemicals: Won't degrade when exposed to juices, mild cleaning agents, or repeated washing.

Brands like Seeway often use HPPE in their ANSI-rated gloves. For tasks requiring extreme sharpness protection with maximum feel, such as sushi preparation or intricate vegetable carving, a thin HPPE glove is often the best tool for the job. This aligns with the needs of clients seeking high-performance food service accessories for professional kitchens.

How Do Coatings Enhance Grip and Durability?

A slippery glove is a dangerous glove. Many cut-resistant liners receive a palm coating to solve this. A nitrile foam or polyurethane (PU) dot coating provides an excellent wet/dry grip on tools and food. This coating also acts as an additional barrier against liquids and abrasion, extending the life of the underlying cut-resistant liner.

When sourcing, consider offering a mix: uncoated HPPE gloves for tasks requiring ultimate sensitivity, and coated versions for general prep, butchering, and cleaning where grip is paramount. This allows kitchens to match the glove to the specific task, optimizing both safety and efficiency.

Conclusion

Selecting the right cut-resistant gloves for kitchen staff requires a careful evaluation of certified cut ratings (EN388/ANSI), explicit food-contact material compliance (FDA/EU), and practical features like washability and grip. Prioritizing gloves made from engineered fibers like HPPE with proper coatings will ensure protection, hygiene, and the dexterity needed in a professional kitchen.

For restaurant chains, food processors, or safety equipment distributors looking to source or develop a line of high-quality, kitchen-specific cut-resistant gloves, partnering with a manufacturer that understands these complex requirements is essential. At AceAccessory, our project managers and QC team can help you navigate these specifications to source or produce gloves that meet the exact demands of your commercial kitchen clients. For a detailed consultation on cut-resistant glove procurement, contact our Business Director, Elaine, at elaine@fumaoclothing.com.