Implementing consistent style standards across accessory collections presents significant challenges for fashion brands and manufacturers. Without systematic approaches, style variations creep into production, brand identity becomes diluted, and customer experiences suffer from inconsistent product quality. Through our extensive experience developing accessories for global brands, we've established proven methodologies for implementing and maintaining style standards that preserve design integrity across production runs and product categories.

Implementing style standards requires creating comprehensive visual and technical documentation, establishing clear quality benchmarks, training all stakeholders on standard requirements, and implementing systematic verification processes throughout design and production.This integrated approach ensures that every accessory consistently reflects brand identity and design intent regardless of production volume or manufacturing location.

Style standards implementation transforms subjective design concepts into objective, measurable criteria that guide every production decision. Let's examine the specific systems and processes that ensure consistent style execution across your accessory collections.

How to create comprehensive style standard documentation?

Without clear documentation, style standards remain subjective interpretations that vary between individuals and departments. Comprehensive documentation transforms abstract style concepts into concrete, actionable guidelines that ensure consistent execution.

Effective style documentation combines visual references, technical specifications, and clear language that leaves no room for ambiguous interpretation across different teams and manufacturing partners.

What should style guide specifications include?

A comprehensive style guide serves as the single source of truth for accessory aesthetics. We develop detailed style manuals that specify exact color standards using Pantone references, material specifications with approved supplier lists, precise dimension tolerances for different components, and explicit construction requirements for various accessory types. For fashion accessories, we include visual mood boards that capture the overall aesthetic feeling, stitch-by-stitch diagrams for complex details, and photographic standards showing correct and incorrect examples of key style elements. This documentation becomes the reference point that aligns designers, product developers, and manufacturing teams on what constitutes acceptable style execution.

How do technical packages translate style into production?

Technical packages bridge the gap between creative vision and manufacturing reality. We create comprehensive tech packs that include precise technical drawings from multiple angles, graded specification sheets for all sizes, bill of materials with approved components, and detailed construction callouts. For accessories with complex styling, we supplement with digital pattern files, 3D renderings that show how elements assemble, and reference samples that embody the style standard. These technical packages eliminate guesswork during production, ensuring that factory teams understand exactly how to execute each style element to meet brand standards consistently.

How to establish clear quality benchmarks?

Style standards without quality benchmarks remain abstract concepts that factories struggle to implement consistently. Clear benchmarks transform style requirements into measurable criteria that can be objectively evaluated throughout production.

Effective benchmarking combines quantitative measurements, visual standards, and functional tests that collectively define what successful style implementation looks like for each accessory type.

What are acceptable quality limits for style elements?

Not every style deviation warrants rejection, but clear limits prevent gradual quality erosion. We establish Acceptable Quality Limits (AQL) specifically for style-critical elements—defining how much color variation is permissible, how much dimensional deviation is acceptable, and how many minor aesthetic flaws can be tolerated before rejection. These limits are category-specific—hair accessories might permit tighter tolerances than casual hats, while luxury scarves would have stricter standards than volume beanies. We document these limits in clear visual guides with magnified examples showing borderline acceptable and unacceptable executions, providing factories with unambiguous criteria for self-assessment before official inspection.

How do reference samples standardize expectations?

Physical references make abstract standards tangible. We create approved reference samples for each accessory style that factories must match in production. These samples are sealed and signed by quality directors to prevent alteration, with specific approved and unapproved comparison samples showing critical style elements. We maintain master sample libraries at our headquarters and provide duplicate reference sets to manufacturing partners. During production, we conduct sample matching sessions where production pieces are compared against references under standardized lighting conditions. This physical benchmarking prevents the subtle style drift that occurs when teams work from memory or imperfect photographs.

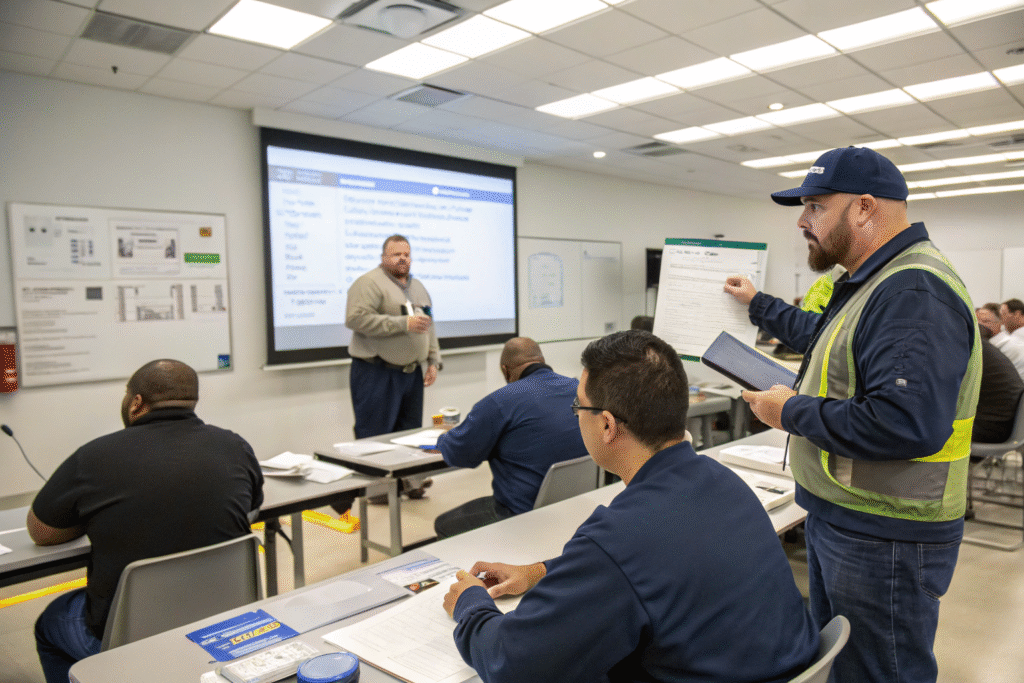

How to train stakeholders on style standards?

Even perfect documentation fails if people don't understand or follow it. Systematic training ensures that everyone involved in the accessory creation process—from designers to factory workers—shares a common understanding of style requirements and their importance.

Effective training combines initial education, ongoing reinforcement, and clear accountability structures that make style standards a shared responsibility across the organization and supply chain.

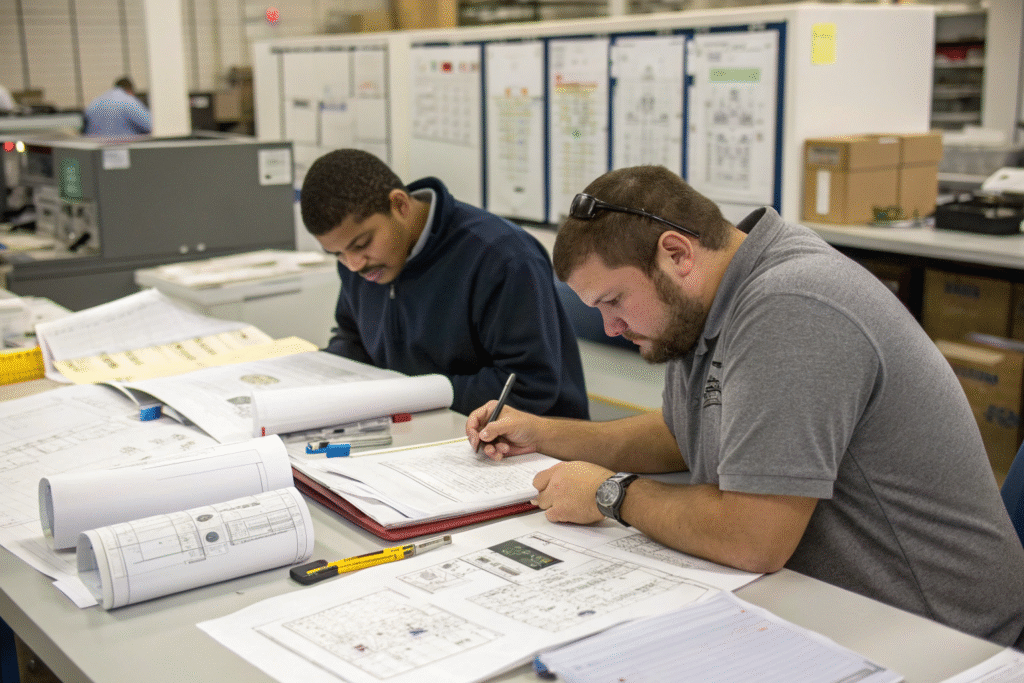

How to conduct effective factory training sessions?

Manufacturing partners cannot implement standards they don't fully understand. We conduct comprehensive factory training that goes beyond simply delivering documents. Our technical teams visit production facilities to conduct hands-on workshops explaining critical style elements, demonstrating proper techniques, and troubleshooting common implementation challenges. We create multilingual visual training aids that overcome language barriers, use magnified comparison displays to highlight subtle differences, and implement certification processes for factory quality teams. This investment in partner education pays dividends through improved first-pass quality and reduced style-related revisions during production.

How to maintain standard awareness across internal teams?

Style standard awareness must extend beyond quality departments to include designers, merchandisers, and product developers. We implement regular standard review sessions where new collections are evaluated against established style benchmarks before production begins. Our cross-functional style committees include representatives from all departments to ensure consistent interpretation and application of standards. We maintain digital standard portals that make the latest documentation instantly accessible to all team members, with version control to prevent confusion from outdated materials. This organizational commitment ensures that style standards remain living guidelines rather than forgotten documents.

How to implement verification processes?

Without systematic verification, style standards gradually erode through production compromises and incremental deviations. Regular verification processes catch deviations early, when corrections are simplest and least costly to implement.

Effective verification combines scheduled audits, production monitoring, and data tracking that provides objective evidence of standard compliance throughout the product lifecycle.

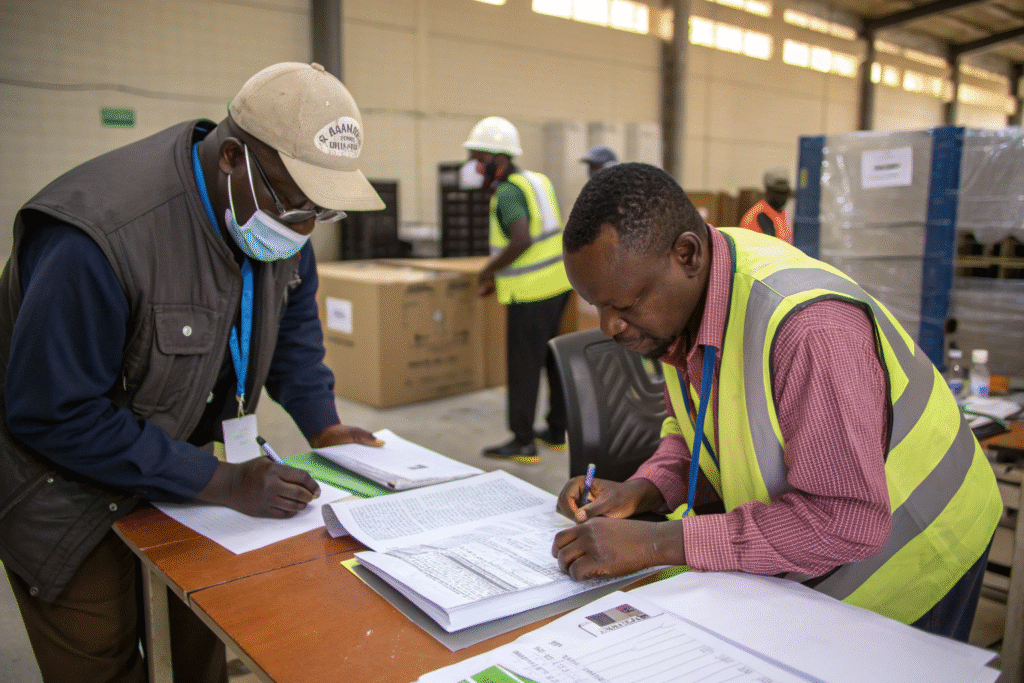

What production audits ensure standard compliance?

Scheduled audits prevent the gradual style drift that occurs when daily production pressures overwhelm quality intentions. We implement regular production audits that evaluate both process adherence and output quality. Our audit teams verify that factories are following approved methods, using specified materials, and maintaining equipment calibration. They randomly pull production samples at various stages to check for style compliance before significant value has been added. Audit findings are documented with photographic evidence and specific corrective actions, with follow-up verification to ensure issues are properly addressed. This systematic monitoring maintains discipline around style standards even during high-pressure production periods.

How does data tracking support style consistency?

Subjective observations cannot reliably maintain standards across global production. We implement data-driven tracking systems that monitor key style metrics across production runs—measuring color consistency with spectrophotometers, verifying dimensions with digital calipers, and documenting material properties with standardized tests. This quantitative data is tracked in statistical process control charts that identify trends toward specification limits before actual breaches occur. The data provides objective evidence for supplier evaluations and helps identify root causes when style deviations occur, enabling continuous improvement in standard implementation.

Conclusion

Implementing style standards for accessories requires a comprehensive system that integrates clear documentation, measurable benchmarks, thorough training, and systematic verification. This integrated approach transforms subjective style concepts into objective, executable standards that preserve brand identity and design integrity across global production networks. Companies that master style standard implementation gain significant competitive advantages through consistent product quality, strengthened brand recognition, and reduced costs associated with style-related revisions and rejections.

If you're looking to implement robust style standards for your accessory collections, we invite you to contact our Business Director, Elaine. Our systematic approach to standard development, training, and verification has helped numerous brands maintain style consistency across global production while reducing quality issues and protecting brand equity. Reach her at: elaine@fumaoclothing.com.