In the fast-paced fashion accessories market, hair clip styles must evolve quickly to meet changing consumer preferences. Many manufacturers struggle with slow development cycles that cause them to miss key market opportunities. At our factory, we've transformed our approach to hair clip style optimization, reducing development time by 40% while significantly improving market success rates.

Improving hair clip style optimization efficiency requires integrating consumer data analysis, streamlined design processes, rapid prototyping capabilities, and data-driven decision making.This systematic approach enables manufacturers to quickly identify winning designs, refine them based on real feedback, and bring successful products to market faster than competitors.

Optimization efficiency isn't about working harder—it's about working smarter. Let's explore the proven strategies that can accelerate your hair clip style development while enhancing commercial success.

How can consumer data accelerate style optimization?

Traditional hair clip development often relies on designer intuition rather than market evidence, leading to hit-or-miss results. Data-driven approaches significantly improve optimization efficiency by focusing resources on styles with proven market potential.

Systematic collection and analysis of consumer data provides objective insights that guide style development toward higher-success probability outcomes.

What sales data reveals winning style elements?

Historical sales data contains invaluable patterns about what hair clip styles resonate with different market segments. We implement advanced sales analytics that break down performance by style elements—clip type, size, color, decoration, and price point. This analysis reveals which combinations drive purchases and which underperform. For example, our data might show that spring-loaded clips in pastel colors outperform similar designs in primary colors among teen markets, while sophisticated tortoiseshell patterns work better for adult professionals. This evidence-based approach prevents wasted development effort on styles with limited market appeal.

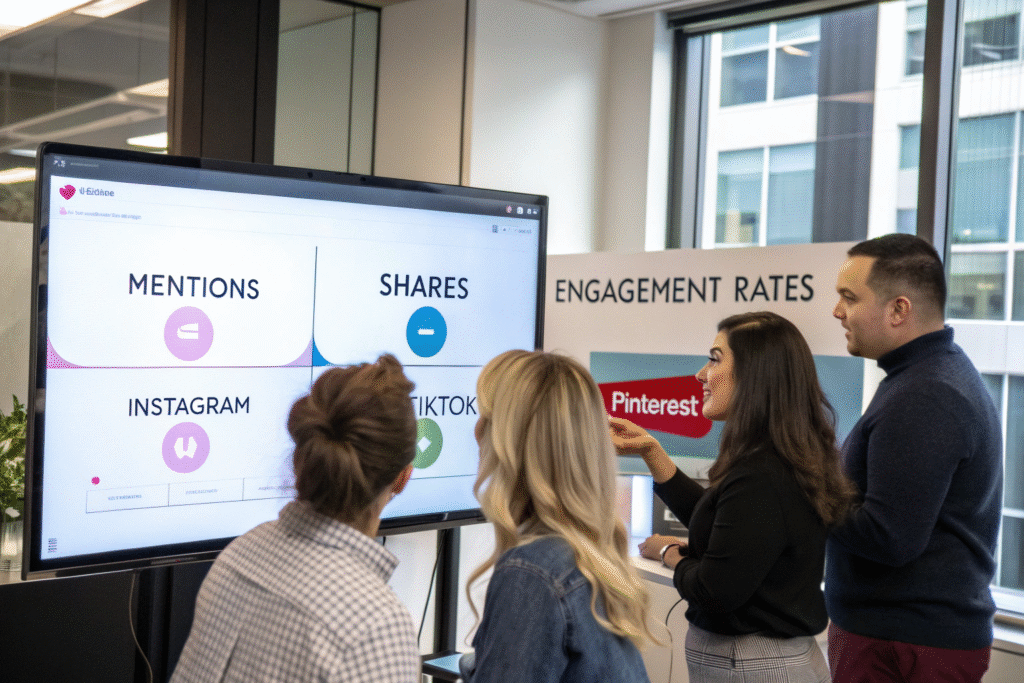

How does social media analysis predict style trends?

Social media platforms provide real-time insights into emerging hair clip preferences. Our marketing team uses social listening tools to track mentions, shares, and engagement rates for various hair clip styles across platforms like Instagram, TikTok, and Pinterest. This analysis identifies rising trends weeks or months before they appear in sales data. We've successfully predicted the resurgence of 90s-inspired clips, minimalist metal designs, and novelty character shapes by monitoring social media conversations and influencer content. This early trend detection allows us to begin optimization while competitors are still recognizing the trend's existence.

What design processes enhance optimization speed?

Inefficient design workflows create significant bottlenecks in style optimization. Traditional sequential processes, where each department works in isolation, dramatically slow development cycles and reduce responsiveness to market feedback.

Implementing integrated, parallel design processes enables faster iteration and more efficient resource utilization throughout the optimization journey.

How does digital prototyping accelerate iteration?

Physical prototyping represents a major time bottleneck in traditional hair clip development. We've implemented comprehensive digital prototyping that allows designers to create, modify, and evaluate virtual hair clip models before committing to physical samples. Our 3D modeling software simulates how different materials will look, how clips will function, and how decorations will appear from various angles. This digital approach enables dozens of design iterations within days instead of weeks. When we do create physical prototypes, they're already highly refined, requiring fewer revision cycles to reach market-ready status.

What parallel development approaches save time?

Sequential development—where design, engineering, and production planning occur in separate stages—dramatically extends optimization timelines. We've adopted parallel development methodologies where cross-functional teams work simultaneously on style concepts. While designers refine aesthetics, engineers address manufacturing feasibility and production planners assess cost implications. This collaborative approach identifies potential issues early, when changes are less costly and time-consuming. Our weekly cross-departmental style review meetings ensure all perspectives inform the optimization process, resulting in styles that are not just beautiful but also manufacturable and commercially viable.

How does rapid testing improve decision quality?

Slow feedback collection represents another major efficiency barrier in style optimization. Traditional market testing methods can take weeks or months, delaying critical decisions and allowing competitors to capture market opportunities.

Implementing accelerated testing protocols provides the timely feedback needed to make confident optimization decisions.

What rapid consumer feedback methods work best?

Slow focus groups and surveys delay optimization decisions. We've developed accelerated feedback systems that gather consumer reactions within days rather than weeks. Our methods include digital concept testing through online panels, in-store intercepts with quick response cards, and social media polls that reach thousands of potential customers. For physical samples, we use pop-up testing stations in high-traffic locations where consumers can handle prototypes and provide immediate feedback. This rapid input allows us to identify the most promising style directions quickly and abandon less promising concepts before investing significant development resources.

How does A/B testing optimize style elements?

Sometimes small details make big differences in hair clip appeal. We implement systematic A/B testing to optimize individual style elements like clasp mechanisms, surface textures, color shades, and decorative elements. Our e-commerce partners help us test variations with live audiences, measuring which specifics drive higher engagement and conversion rates. This granular testing has revealed surprising preferences—such as matte finishes outperforming glossy ones for certain demographics, or specific clasp types significantly impacting perceived quality. This data-driven approach to detail optimization ensures every element contributes to the style's market success.

How can production preparation accelerate market entry?

Even perfectly optimized styles face delays if production systems aren't prepared for efficient manufacturing. Traditional approaches where production planning begins after final design approval create unnecessary bottlenecks in the path to market.

Integrating production preparation into the optimization process enables seamless transition from approved style to volume manufacturing.

How does early tooling planning save time?

Tooling and mold development often represents a critical path item in hair clip manufacturing. We've implemented early tooling assessment where production engineers evaluate design concepts for manufacturing feasibility while optimization is still underway. This proactive approach identifies potential tooling challenges before designs are finalized, allowing for adjustments that maintain style integrity while ensuring efficient production. For complex clip mechanisms, we sometimes begin prototype tooling development before final design approval, shaving weeks off the overall timeline. This parallel preparation has reduced our tooling-related delays by over 60%.

What supplier collaboration enhances readiness?

Material and component availability can delay production of even the most optimized styles. We maintain collaborative relationships with our key suppliers, sharing style concepts during development to ensure material availability when production begins. This early engagement allows suppliers to prepare specialty materials, source unique components, or adjust their production schedules to accommodate our timeline. For decorations like crystals, prints, or special finishes, we involve decoration specialists during the optimization phase to ensure their technical requirements are considered in the design. This supply chain integration has significantly improved our speed to market for new hair clip styles.

Conclusion

Improving hair clip style optimization efficiency requires a holistic approach that integrates consumer insights, streamlined processes, rapid testing, and production preparation. By implementing these interconnected strategies, manufacturers can significantly reduce development timelines while increasing the commercial success of new styles. The most efficient optimization systems balance speed with intelligence—moving quickly without sacrificing the data-driven decision making that ensures market relevance. Companies that master this balance gain significant competitive advantages through faster response to trends and higher success rates for new product introductions.

If you're looking to enhance your hair clip style optimization efficiency, we invite you to contact our Business Director, Elaine. Our integrated approach to style development has helped numerous brands accelerate their product cycles while improving market performance. Reach her at: elaine@fumaoclothing.com.