Hairband quality issues can damage your brand reputation and lead to significant financial losses. From broken elastics to fading colors and uncomfortable designs, these problems often surface only after products reach consumers. At our factory, we've developed comprehensive quality risk management systems that prevent these issues before they occur, saving our clients from costly returns and brand damage.

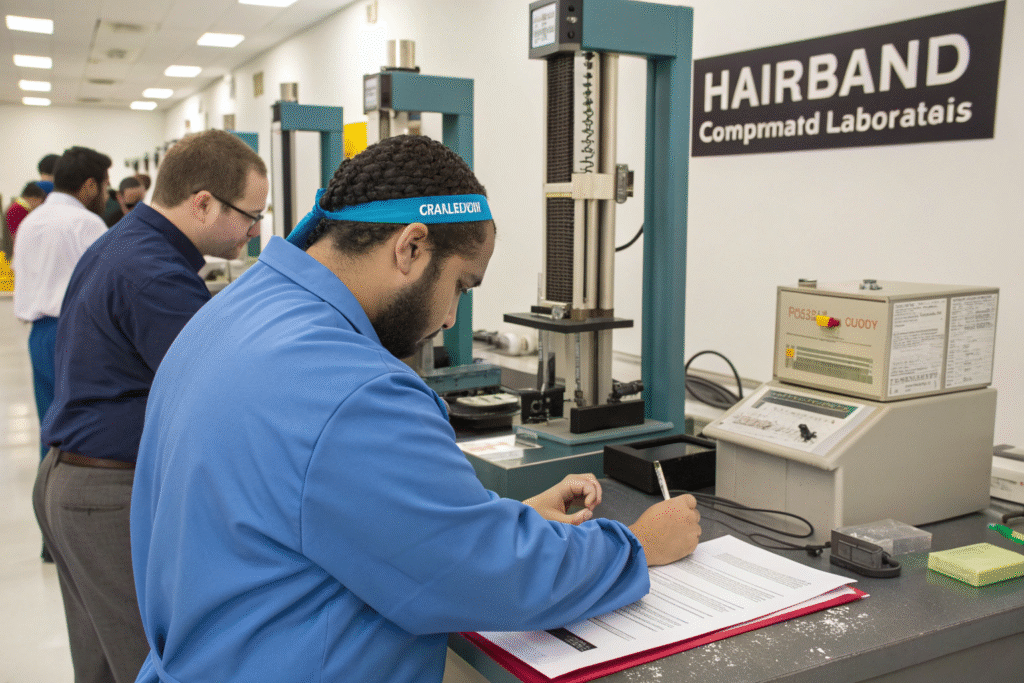

Effective hairband quality risk control requires a proactive, systematic approach that addresses potential failures at every stage—from material selection and production to final inspection.This involves implementing rigorous testing protocols, establishing clear quality standards, and maintaining consistent monitoring throughout the manufacturing process.

Controlling quality risks isn't about finding defects—it's about preventing them. Let's examine the strategic framework that ensures hairband quality remains consistently high across production runs.

How can material selection minimize quality risks?

The foundation of hairband quality begins with raw materials. Many quality failures stem from inappropriate material choices that seem cost-effective initially but lead to product failures and customer dissatisfaction.

Selecting the right materials based on scientific testing and performance requirements significantly reduces risks related to elasticity loss, breakage, color fading, and skin irritation.

What material testing prevents elasticity failure?

Elasticity degradation represents one of the most common hairband quality issues. We implement comprehensive elastic testing that evaluates recovery rates after repeated stretching, tension retention over time, and performance under different environmental conditions. Our quality team tests elastic materials against industry standards and custom benchmarks based on specific product requirements. This includes accelerated aging tests that simulate months of use within days, helping us identify materials that maintain their stretch properties long-term. By establishing strict material specifications and conducting batch-by-batch verification, we ensure the elastics in your hairbands perform consistently throughout their expected lifespan.

How does colorfastness testing protect brand appearance?

Color bleeding or fading can ruin otherwise functional hairbands. We subject all dyed materials to rigorous colorfastness testing including wash tests, rub tests, light exposure tests, and perspiration tests. These evaluations determine how colors withstand washing, friction, sunlight, and contact with skin. Our laboratory uses standardized testing equipment and controlled conditions to ensure consistent results. For specific markets or client requirements, we implement even stricter testing protocols. This systematic approach prevents the embarrassment of color transfer to clothing or hair, protecting your brand's reputation for quality and attention to detail.

What production controls ensure consistent quality?

Even with perfect materials, production processes can introduce quality variations. Without proper controls, minor process deviations can lead to significant quality issues in finished hairbands.

Implementing standardized procedures, equipment maintenance protocols, and in-process checks creates a manufacturing environment where quality consistency becomes inherent to the production system.

How does process standardization prevent defects?

Consistent processes yield consistent products. We've developed detailed work instructions for every production stage—from cutting elastic materials to sewing seams and applying decorations. These standardized procedures ensure every operator follows the same methods, eliminating variations that can lead to quality issues. Our production supervisors conduct regular process audits to verify adherence to these standards. Additionally, we maintain comprehensive documentation for each production batch, creating traceability that allows us to identify and address process deviations immediately. This systematic approach has reduced production-related defects by over 60% in our hairband manufacturing.

What equipment maintenance ensures manufacturing precision?

Properly maintained equipment is essential for quality consistency. We implement preventive maintenance schedules for all production machinery, including cutting machines, sewing equipment, and printing devices. Our maintenance team follows manufacturer recommendations while also developing custom maintenance protocols based on our specific usage patterns and quality requirements. Regular calibration of measurement devices and tension controls ensures that every hairband meets dimensional specifications. This attention to equipment maintenance prevents issues like inconsistent sizing, uneven stitching, or improper elastic tension that can compromise product quality and user comfort.

How does inspection methodology catch potential issues?

Strategic inspection protocols serve as the final defense against quality risks. However, effective inspection goes beyond simple final checking—it involves multiple verification points throughout production.

A layered inspection approach identifies potential issues at the earliest possible stage, preventing the amplification of defects and reducing correction costs.

Why implement in-process quality checks?

Final inspection alone cannot effectively control quality risks. We've established multiple quality checkpoints throughout production: after material preparation, during assembly, after decoration application, and before packaging. At each checkpoint, trained quality staff verify critical parameters using standardized measurement tools and acceptance criteria. This approach allows us to detect and address issues immediately, preventing the production of large quantities of defective products. For hairbands, we specifically check elastic tension consistency, seam integrity, decoration attachment strength, and dimensional accuracy at these in-process stages.

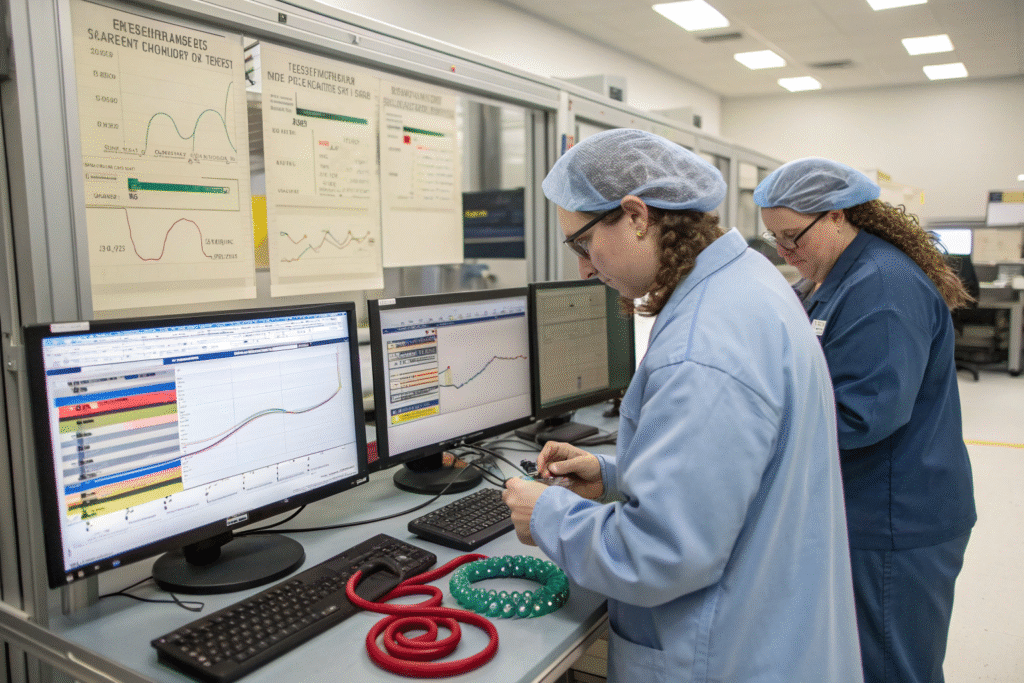

How does statistical process control predict quality trends?

Reactive inspection identifies existing problems, but statistical methods predict future issues. We employ statistical process control (SPC) techniques to monitor production quality trends. By collecting and analyzing data on key quality characteristics—such as elastic recovery rates, size variations, and defect frequencies—we can identify trends that may indicate developing problems. Our quality team uses control charts to distinguish between normal process variation and signals that require intervention. This data-driven approach enables proactive adjustments before quality breaches occur, ensuring consistent hairband quality across production runs and over time.

How does supplier management impact quality control?

Your manufacturer's relationships with material suppliers significantly impact final product quality. Consistent hairband quality requires reliable raw materials that meet specifications batch after batch.

Implementing robust supplier qualification, performance monitoring, and collaboration systems ensures that quality begins at the source rather than being inspected in later.

What supplier qualification prevents material issues?

Not all material suppliers maintain consistent quality standards. We implement comprehensive supplier qualification processes that evaluate potential partners based on their quality systems, production capabilities, testing facilities, and track record. Before approving new suppliers, we conduct facility audits, review their quality documentation, and test sample materials extensively. For existing suppliers, we perform regular reassessments to ensure continued compliance with our standards. This rigorous qualification process has helped us build a network of reliable partners who understand our quality requirements and consistently deliver materials that meet them.

How does collaborative improvement enhance quality?

The best manufacturer-supplier relationships focus on continuous improvement rather than simple compliance. We establish quality collaboration programs with our key suppliers, sharing performance data, discussing improvement opportunities, and jointly addressing quality challenges. This collaborative approach has led to material enhancements that benefit our clients—such as elastics with better recovery properties, fabrics with improved color retention, and decorations with stronger adhesion. By treating suppliers as quality partners rather than just vendors, we create relationships that drive innovation and prevent quality issues before they can affect your hairband products.

Conclusion

Controlling hairband quality risks requires a comprehensive, systematic approach that addresses potential failures at multiple levels—from material selection and supplier management through production controls and strategic inspection. This proactive quality philosophy prevents issues rather than simply detecting them, resulting in consistently reliable products that protect your brand reputation and reduce costs associated with returns and replacements. Companies that implement these robust quality risk control systems gain significant competitive advantages through enhanced customer satisfaction and reduced quality-related disruptions.

If you're looking for a manufacturing partner with proven systems for controlling hairband quality risks, we invite you to contact our Business Director, Elaine. Our quality management approach has helped numerous brands maintain consistent product excellence while minimizing quality-related issues. Reach her at: elaine@fumaoclothing.com.