Hair tie quality issues can damage your brand reputation and eat into your profits. When customers receive hair ties that break easily, lose elasticity quickly, or have inconsistent sizing, they're unlikely to make repeat purchases. We understand these frustrations from working with numerous brands across global markets.

Improving hair tie pass rates and accuracy requires a comprehensive approach focusing on material selection, manufacturing precision, quality control systems, and supplier capability.By addressing these key areas, you can significantly reduce defects and ensure every hair tie meets your exact specifications for durability, elasticity, and appearance.

Let's explore practical strategies that manufacturers and brands can implement to achieve higher quality standards in hair tie production.

What materials selection impacts hair tie durability?

Choosing the right materials is the foundation of hair tie quality. Many manufacturers cut corners on material quality to reduce costs, but this inevitably leads to higher failure rates and customer complaints.

The material composition directly affects elasticity retention, breakage resistance, and overall lifespan. High-quality materials may cost slightly more initially but prevent expensive returns and brand damage in the long run.

How does elastic fiber quality affect performance?

The core elastic fibers determine how well a hair tie maintains its stretch over time. We use high-quality spandex and natural rubber blends that provide consistent elasticity without over-stretching. Premium elastic materials recover their original shape after use, while inferior materials lose tension quickly. Our material testing includes stretch recovery tests where we measure how well hair ties return to their original size after repeated stretching. This ensures your customers get hair ties that don't become loose after just a few uses.

Why does fabric covering matter beyond aesthetics?

The outer fabric covering does more than just look pretty—it protects the elastic core and affects grip. We select soft but durable fabrics that won't snag or pull hair. The fabric must have enough stretch to not constrain the elastic core while being tight enough to prevent shifting. Through fabric compatibility testing, we ensure the covering material works harmoniously with the core elastic. This attention to material pairing prevents common issues like fabric tearing or separation from the elastic core during normal use.

How can manufacturing processes enhance accuracy?

Precision in manufacturing directly correlates with product consistency. Even with perfect materials, sloppy production processes will yield inconsistent results that fail quality checks.

Implementing standardized operating procedures, maintaining equipment properly, and training operators thoroughly ensures every hair tie meets exact specifications batch after batch.

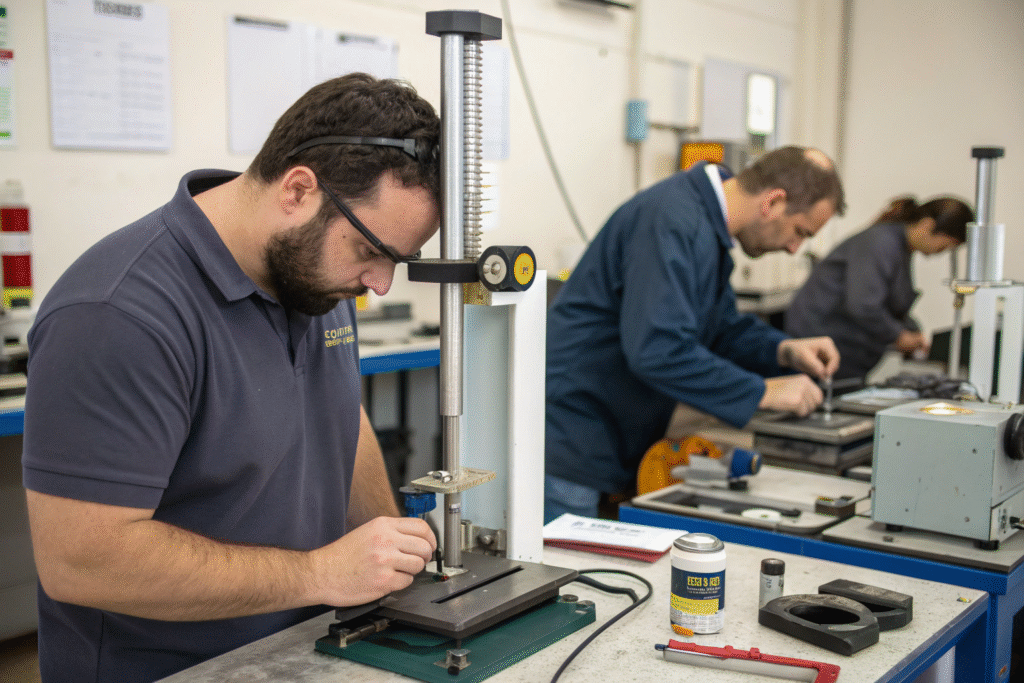

What role does equipment calibration play?

Properly calibrated machinery ensures consistent sizing and stitching accuracy. Our production equipment undergoes regular maintenance and calibration checks to maintain precision in cutting, sewing, and finishing. We maintain detailed equipment maintenance logs that track performance metrics and calibration schedules. This systematic approach prevents variations in hair tie dimensions and ensures every piece matches your specified measurements exactly. Consistent sizing might seem minor, but it's crucial for both quality perception and functional performance.

How important are operator skill and training?

Even with automated processes, human oversight remains critical. Our production staff receive comprehensive training on quality standards and defect recognition. We conduct regular training sessions focused on identifying early signs of production issues, such as inconsistent tension or improper seam alignment. This human quality layer catches problems that machines might miss. Well-trained operators can adjust equipment in real-time and prevent small issues from becoming batch-wide defects, significantly improving first-pass yield rates.

What quality control measures prevent defects?

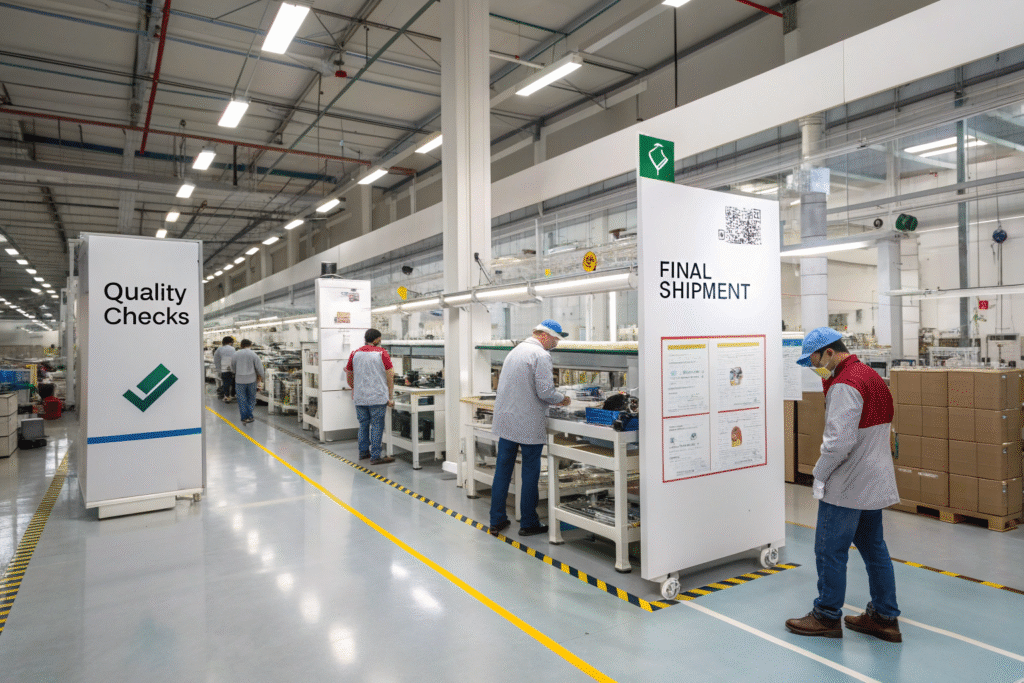

Robust quality control systems catch defects before they reach your customers. Many manufacturers rely on end-line inspection alone, but effective quality control must be integrated throughout the production process.

Implementing multiple inspection points, establishing clear acceptance criteria, and using statistical process control methods dramatically reduce defect rates in hair tie manufacturing.

Why implement in-process quality checks?

Waiting until final inspection to check quality means discovering problems after significant production has occurred. We implement quality checkpoints at multiple stages: raw material inspection, during elastic core production, after covering application, and at finishing. This multi-stage approach allows us to identify and address issues immediately, preventing the amplification of defects through subsequent processes. Early detection means less waste and higher overall pass rates for your orders.

How does statistical process control help?

Using statistical methods to monitor production consistency provides objective data for quality improvement. We track key metrics like elasticity variance, size consistency, and break strength using control charts. This data-driven approach helps us identify trends and make proactive adjustments before specifications are breached. For our clients, this means more consistent products and fewer surprises with final inspection results. The data also provides valuable insights for continuous improvement across production runs.

How does supplier capability affect final quality?

Your manufacturer's overall capability and systems ultimately determine the consistency and reliability of your hair ties. The most beautiful design will underperform if produced by a factory lacking proper systems and expertise.

Choosing a manufacturer with strong technical capability, robust systems, and proven experience in hair accessories ensures your quality standards can be consistently met at scale.

Why does technical expertise matter?

Hair tie manufacturing involves specific technical knowledge about elastic materials, joining methods, and finishing techniques. Our technical team includes specialists in textile engineering and elastic products who understand the material science behind high-performance hair ties. This expertise allows us to recommend optimal construction methods for your specific design and price point. When issues arise, our technical depth enables rapid root cause analysis and effective solutions, minimizing production disruptions.

How important are management systems?

Quality doesn't happen by accident—it requires systematic approaches. Our factory management systems ensure consistency through documented procedures, clear responsibility assignments, and performance tracking. We maintain comprehensive quality management systems that cover everything from material sourcing to final shipment. These systems provide the framework that enables us to deliver consistent quality, order after order. For you, this means reliability and peace of mind knowing your products are in capable hands.

Conclusion

Improving hair tie pass rates and accuracy requires a holistic approach addressing materials, processes, quality control, and supplier capabilities. By focusing on these interconnected areas, brands can significantly reduce defects, enhance customer satisfaction, and protect their brand reputation. Remember that quality is built into the product at every stage, not just inspected in at the end.

If you're looking for a manufacturing partner committed to delivering high-pass-rate hair ties with precise accuracy, we invite you to contact our Business Director, Elaine. She can discuss your specific quality requirements and how our systems and expertise can help achieve them. Reach her at: elaine@fumaoclothing.com.