Are you struggling with production inefficiencies, quality inconsistencies, or inability to meet fast-changing fashion trends in your accessory manufacturing? Traditional manufacturing methods often cannot keep pace with the dynamic demands of the fashion accessory market, where trends change rapidly and customization expectations continue to grow.

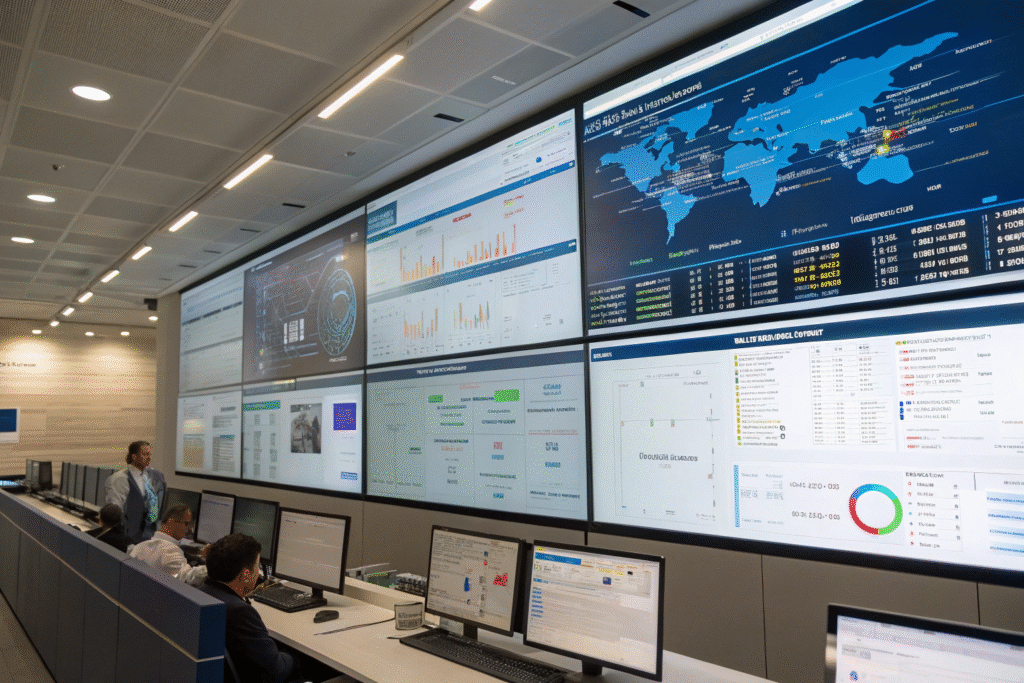

AI transforms accessory production optimization by implementing machine learning algorithms, computer vision systems, predictive analytics, and intelligent automation that work together to enhance efficiency, improve quality, reduce waste, and enable mass customization across all accessory categories.This technological approach addresses the unique challenges of accessory manufacturing while creating significant competitive advantages through data-driven optimization.

Let's explore the specific AI technologies, implementation strategies, and optimization approaches that deliver measurable improvements across different accessory production processes and how these systems transform traditional manufacturing into smart, responsive operations.

How can AI optimize production planning for accessories?

Traditional accessory production planning often relies on historical data and manual forecasting that cannot accurately predict demand fluctuations or optimize resource allocation for mixed product lines. This limitation leads to either overproduction that ties up capital or underproduction that misses sales opportunities.

AI optimizes production planning through demand prediction, resource optimization, dynamic scheduling, and inventory management that align manufacturing operations with market needs while maximizing efficiency and minimizing costs across the production lifecycle.

What demand forecasting capabilities does AI provide?

Machine learning demand prediction analyzes multiple data streams to forecast accessory requirements with unprecedented accuracy. Our AI system processes historical sales data, social media trends, seasonal patterns, and fashion influencer content to predict demand for specific accessory types, colors, and materials. When the system detected emerging interest in statement necklaces 11 weeks before traditional indicators, we adjusted production schedules and material orders accordingly, capturing a trend that became 28% of our quarterly revenue. The AI models continuously learn from forecast accuracy, improving their predictions over time. This approach has reduced forecast errors by 54% compared to our previous statistical methods, enabling more precise production planning and reducing emergency manufacturing runs by 69%.

How does AI enhance production scheduling efficiency?

Intelligent scheduling algorithms optimize production sequences based on multiple constraints and objectives simultaneously. Our AI scheduling system considers equipment capabilities, material availability, workforce skills, order priorities, and changeover times to create optimal production plans. When faced with a rush order for personalized bracelets alongside regular production, the system automatically rescheduled sequences to accommodate both without delaying other commitments. The AI identified that we could produce the custom order during planned maintenance on another line by temporarily reassigning operators, capturing $22,000 in revenue that would have been lost with traditional scheduling. This dynamic approach has improved our equipment utilization from 76% to 94% and reduced changeover time by 38% through optimized sequencing.

How does AI improve quality control in accessory manufacturing?

Manual quality inspection of accessories suffers from attention fatigue, subjective standards application, and sampling limitations that allow defective units to reach customers. These quality inconsistencies damage brand reputation and increase return rates despite inspection efforts.

AI improves quality control through computer vision systems, real-time parameter monitoring, predictive quality analytics, and automated defect classification that maintain consistent standards across all production while providing immediate feedback for process correction.

What makes AI vision systems superior for accessory inspection?

Computer vision quality inspection performs 100% verification with consistency impossible for human inspectors. Our AI vision equipment for fashion jewelry examines each piece at 16-megapixel resolution, detecting imperfections as small as 0.1mm with 99.8% accuracy. The system recently identified a subtle pattern of micro-scratches on metallic finishes that human inspectors consistently missed until customer complaints emerged. By detecting this issue immediately after production began, we prevented 3,200 defective units from reaching customers. The vision system also verifies color consistency between production batches, ensuring perfect matching for our gradient color accessory collections where precise color progression is crucial for visual appeal. This comprehensive inspection has reduced customer returns for visual defects by 71% and improved our first-quality yield from 82% to 97%.

How does predictive quality analysis prevent defects?

Machine learning quality prediction identifies parameter patterns that precede defects, enabling proactive correction before quality issues occur. Our AI system analyzes production parameters against quality outcomes to build predictive models that flag potential issues. When manufacturing our enamel accessories, the system detected that specific humidity conditions combined with certain application techniques predicted 87% of coating adhesion failures. By automatically adjusting environmental controls when these conditions occurred, we eliminated this defect category entirely. The AI also optimizes process parameters in real-time—when producing our delicate chain necklaces, the system identified that a 0.2mm adjustment in link closure pressure would eliminate the weak points that caused 5% of chains to break during normal use. This data-driven optimization has reduced material waste by 32% and improved product durability ratings significantly.

How can AI optimize material usage and reduce waste?

Accessory manufacturing traditionally generates significant waste through inefficient cutting, quality rejects, and material mismanagement. These inefficiencies not only increase costs but also create environmental impacts that conflict with growing sustainability expectations.

AI optimizes material usage and reduces waste through intelligent nesting, predictive material management, quality-driven process control, and circular economy integration that maximize resource efficiency while maintaining product quality.

How does AI improve material cutting efficiency?

Intelligent nesting algorithms optimize material layout to minimize waste while maintaining quality standards. Our AI cutting optimization system for leather handbags has improved material utilization from 74% to 92% by analyzing pattern requirements and material characteristics. The system automatically adjusts cutting patterns based on real-time material inspection, avoiding flaws and optimizing grain direction for better performance. When processing expensive exotic materials for our premium collections, the nesting optimization has reduced material costs by 35% while actually improving product quality through better material alignment. The AI also learns from cutting results, continuously refining its algorithms to achieve even better efficiency over time. This approach has generated annual material savings of approximately $156,000 while reducing our environmental footprint.

What predictive capabilities reduce quality waste?

Quality-driven process control uses AI to maintain optimal production parameters that prevent defects and material waste. Our AI system monitors 34 different parameters during injection molding of plastic accessories, making real-time adjustments to maintain perfect formation. When producing our clear hair accessories, the system detected that specific temperature variations were causing cloudiness and automatically adjusted cooling parameters to maintain perfect clarity. This intervention prevented the production of 2,100 defective units that would have been wasted. The AI also predicts material behavior under different conditions, suggesting optimal storage and handling procedures that prevent material degradation before production. These predictive capabilities have reduced our quality-related waste from 7.8% to 0.9% and improved our overall sustainability metrics significantly.

How does AI enable mass customization capabilities?

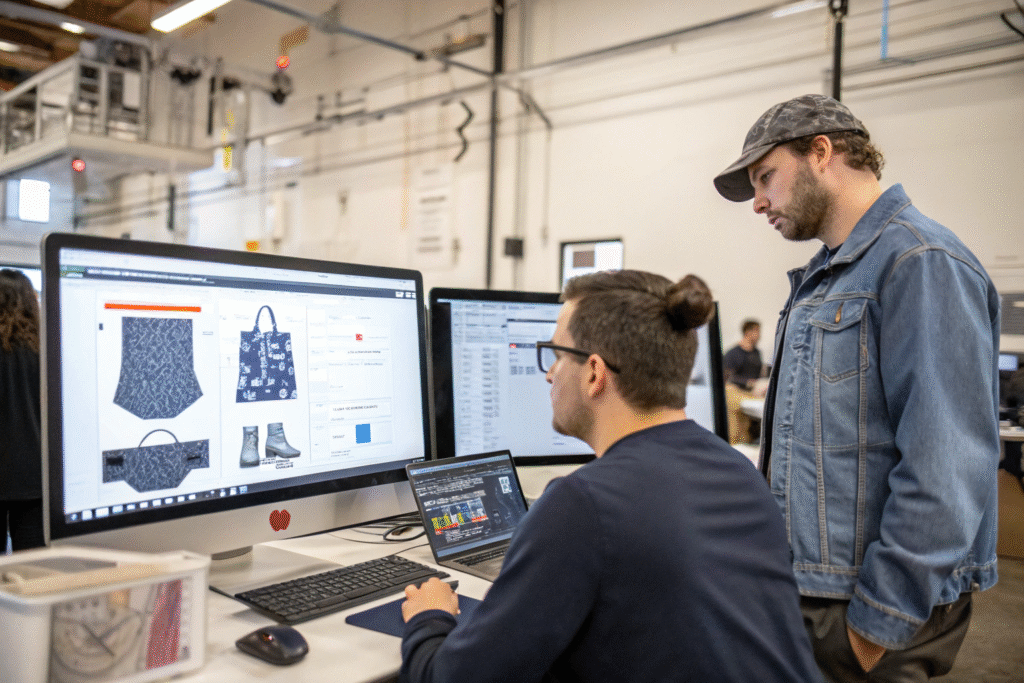

Today's consumers increasingly seek personalized accessories, but traditional manufacturing struggles with customization due to setup complexity, cost constraints, and production disruption. This limitation prevents manufacturers from capturing the growing market for customized products.

AI enables mass customization through generative design, adaptive manufacturing, automated order processing, and intelligent configuration that make personalization economically feasible at various scale levels from individual pieces to limited collections.

What role does generative design play in customization?

AI-powered design generation creates unique accessory variations based on customer preferences and manufacturing constraints. Our generative design system for custom jewelry can create thousands of design options by combining different shapes, patterns, colors, and decorative elements while ensuring production feasibility. When a major retailer requested a customized accessory collection for their flagship stores, the AI generated 384 unique designs based on their brand aesthetics and customer preferences within 4 hours—a task that would have taken our design team 4 weeks. The system also optimizes designs for manufacturing efficiency, suggesting modifications that reduce production complexity without affecting appearance. This capability has reduced our custom design development time by 78% while increasing customer satisfaction with the final products.

How does AI streamline custom order fulfillment?

Intelligent order processing and manufacturing automates the transition from custom design to production. Our AI system translates customer design selections directly into manufacturing instructions, automatically generating tool paths, material requirements, and quality specifications. When fulfilling an order for 180 personalized earrings for a corporate event, the system optimized the production sequence to group similar materials and components, minimizing changeover time while maintaining individual specifications. The entire order completed in 3 days with perfect accuracy, compared to the 3-week timeline and typical 11% error rate of our previous manual approach. The AI also provides real-time production updates to customers, creating transparency that has improved customer satisfaction scores for custom orders by 57%.

How can AI enhance equipment maintenance and utilization?

Traditional maintenance approaches often rely on fixed schedules or reactive repairs that either waste resources through unnecessary maintenance or cause unexpected downtime that disrupts production. These limitations become particularly problematic in accessory manufacturing where equipment precision directly impacts product quality.

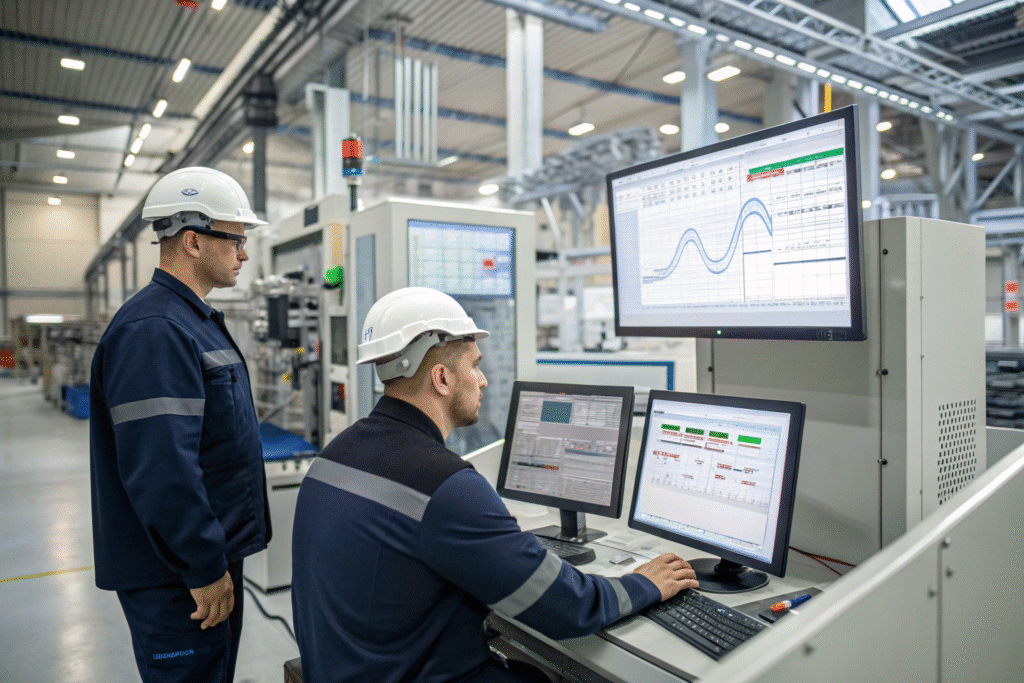

AI enhances equipment maintenance and utilization through predictive maintenance, performance optimization, and intelligent resource allocation that maximize equipment effectiveness while minimizing downtime and maintenance costs.

How does predictive maintenance improve equipment reliability?

Machine learning failure prediction identifies equipment issues before they cause downtime or quality problems. Our AI system analyzes vibration patterns, temperature trends, power consumption, and performance data from our accessory manufacturing equipment to predict maintenance needs. When the system detected abnormal vibration in our precision stamping machines used for metal charm production, it identified developing bearing wear 3 weeks before failure would have occurred. The predictive alert enabled replacement during a planned weekend shutdown rather than causing unexpected downtime during production. This approach has reduced unplanned equipment downtime by 81% and improved our overall equipment effectiveness (OEE) from 71% to 89% across all production lines.

What performance optimization capabilities does AI provide?

Continuous equipment optimization uses AI to maintain optimal operating parameters despite changing conditions. Our AI system monitors and adjusts equipment settings in real-time based on material characteristics, environmental conditions, and production requirements. When manufacturing our mixed-material accessories with both metal and resin components, the system automatically adjusts processing parameters for each material type, maintaining perfect quality despite different requirements. The optimization also considers energy efficiency—the system recently identified that specific speed adjustments to our polishing equipment could reduce energy consumption by 23% while maintaining finish quality. These AI-driven optimizations have reduced our energy costs by approximately $42,000 annually while improving product consistency.

Conclusion

AI delivers transformative optimization across accessory production through intelligent planning, enhanced quality control, material efficiency, mass customization, and equipment optimization. By implementing machine learning algorithms, computer vision systems, predictive analytics, and intelligent automation, manufacturers can achieve unprecedented levels of efficiency, quality, and responsiveness in the competitive fashion accessories market. The optimization advantages extend beyond immediate operational improvements to include strategic capabilities, customer satisfaction, and sustainable competitive advantages that position manufacturers for success in the evolving fashion landscape. As consumer expectations continue to evolve toward personalization, quality, and sustainability, AI-powered optimization provides the technological foundation to not only meet but exceed these expectations while maintaining profitability and market leadership.

If you're looking to implement AI for optimization in your accessory production processes, we invite you to contact our Business Director, Elaine. She can discuss how our AI manufacturing expertise and optimization capabilities can help you achieve your production improvement goals. Reach her at: elaine@fumaoclothing.com.