Are you struggling with inconsistent bag quality, unexpected equipment failures, or inefficient resource utilization in your bag manufacturing operations? Traditional monitoring methods often provide delayed or incomplete insights into production parameters, making it difficult to maintain consistent quality and optimize manufacturing processes.

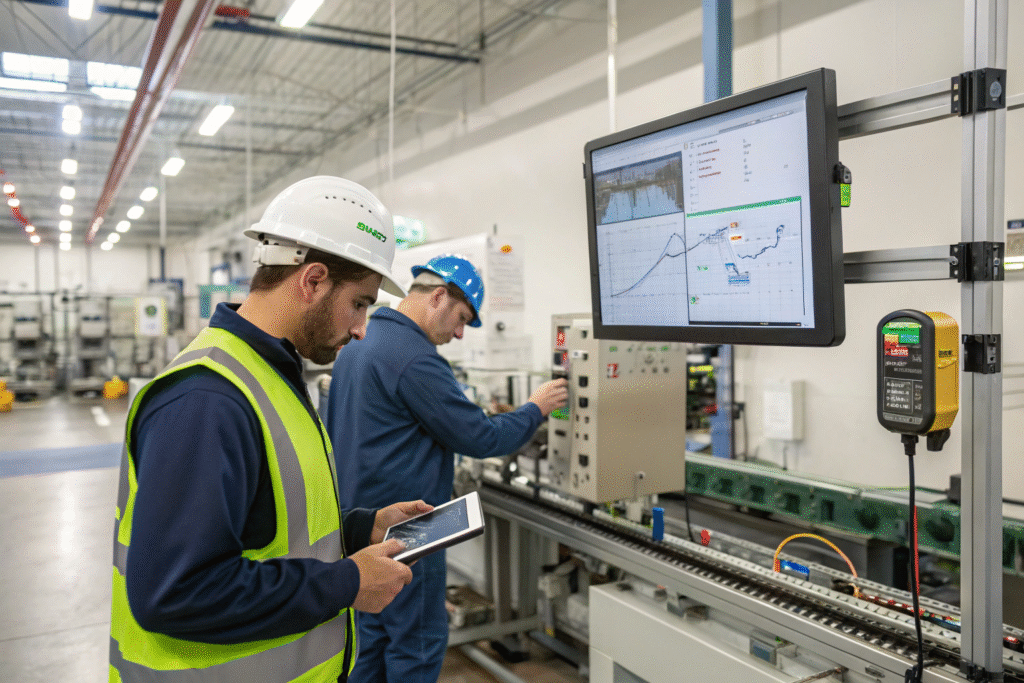

IoT transforms bag production parameter monitoring by deploying connected sensors, real-time data collection, cloud analytics, and automated control systems that work together to provide comprehensive visibility into every aspect of the manufacturing process from material preparation to final assembly.This technological approach enables manufacturers to maintain optimal production conditions, prevent quality issues, and maximize equipment efficiency through continuous, data-driven monitoring.

Let's explore the specific IoT technologies, implementation strategies, and integration approaches that enable effective parameter monitoring across different bag production processes and how these systems deliver measurable improvements in quality, efficiency, and cost management.

What are the key IoT sensors for bag production monitoring?

Traditional bag manufacturing relies on periodic manual checks and operator experience to maintain production parameters, leading to inconsistencies, undetected deviations, and reactive problem-solving. These limitations become particularly problematic with complex bag constructions and premium materials where parameter precision directly impacts quality.

The key IoT sensors for bag production monitoring include environmental sensors, equipment performance monitors, material condition trackers, and quality validation systems that collectively capture critical parameters throughout bag manufacturing. These sensors provide the foundational data for proactive quality management and process optimization.

How do environmental sensors maintain optimal production conditions?

Climate and environmental monitoring ensures consistent production conditions that significantly impact material behavior and manufacturing quality. Our IoT implementation uses temperature, humidity, and particulate sensors throughout our leather bag production facility to maintain optimal conditions for different materials. The system automatically adjusts environmental controls when producing sensitive suede handbags, maintaining 45-55% humidity to prevent material brittleness. When manufacturing technical backpacks with waterproof coatings, the system ensures temperature remains within the 18-22°C range required for proper adhesive curing. This environmental consistency has reduced material-related defects by 38% and improved color matching accuracy by 27% across production batches. The system recently prevented a potential quality issue by detecting a humidity spike in our fabric storage area that could have affected 2,000 units of canvas tote bags, enabling corrective action before production began.

What equipment performance parameters require continuous monitoring?

Machine health and performance tracking identifies equipment issues before they impact product quality or cause production stoppages. Our IoT sensors monitor 14 performance parameters on each industrial sewing machine, including needle temperature, thread tension, motor current, and vibration patterns. When producing our structured leather bags, the system detected abnormal vibration in a critical stitching machine that indicated imminent bearing failure. The predictive maintenance alert enabled replacement during a planned break rather than causing unexpected downtime during production. For our high-frequency ultrasonic welding equipment used in synthetic bag production, the system monitors energy consumption and output consistency to ensure proper seam sealing. This comprehensive equipment monitoring has reduced unplanned downtime by 73% and improved stitch quality consistency by 41% across all bag production lines.

How to implement IoT for material parameter monitoring?

Bag manufacturing involves diverse materials with specific handling requirements and sensitivity to environmental conditions. Traditional material management often relies on visual inspection and manual records that cannot capture the subtle parameter variations that affect manufacturing quality and consistency.

Implementing IoT for material parameter monitoring involves material condition tracking, storage environment control, usage optimization, and quality correlation that ensure materials maintain optimal characteristics throughout the production process. This proactive approach prevents material-related quality issues before they affect production.

What material conditions significantly impact bag quality?

Real-time material characteristic monitoring tracks parameters that directly affect manufacturing outcomes and final product quality. Our IoT system monitors leather humidity content (optimal: 12-18%), fabric tension during cutting, and adhesive temperature during application. When producing our premium leather briefcases, the system detected that a recent leather shipment had 22% moisture content—outside the optimal range for precise cutting and stitching. The system automatically routed this batch to a controlled drying environment before production, preventing the dimensional instability issues that previously would have affected 400 units. For our nylon backpack production, the system monitors material roll tension to ensure consistent feeding into cutting machines, reducing pattern distortion by 63% and improving material utilization by 17% through optimized nesting.

How does IoT optimize material usage and reduce waste?

Precision material management uses IoT data to minimize waste while maintaining quality standards. Our smart cutting systems use pressure sensors and vision systems to optimize material nesting based on real-time material characteristics. When processing patterned fabrics for our designer handbag collection, the system automatically adjusts cutting patterns to maintain pattern alignment while maximizing material usage. This approach has reduced fabric waste by 34% compared to manual cutting methods. The IoT system also tracks material consumption against production output, identifying inefficiencies that previously went unnoticed. Recently, the data revealed that our vinyl material usage was 18% higher than theoretical requirements due to suboptimal cutting patterns. By implementing IoT-driven optimization, we achieved annual material savings of approximately $86,000 while maintaining the same production output.

How can IoT enhance sewing and assembly parameter control?

Sewing and assembly operations involve numerous parameters that collectively determine bag quality, durability, and appearance. Traditional quality control typically occurs after completion, allowing parameter deviations to affect multiple units before detection and correction.

IoT enhances sewing and assembly parameter control through real-time stitch monitoring, component verification, assembly sequence validation, and automated quality assurance that maintains optimal parameters throughout production. This continuous control prevents defects rather than detecting them after occurrence.

What sewing parameters benefit from IoT monitoring?

Comprehensive stitch quality tracking monitors multiple parameters that collectively determine seam quality and durability. Our IoT-enabled sewing machines track stitch length (optimal: 2.5-3.0mm for bag seams), thread tension (monitored via motor current analysis), needle temperature (alert threshold: 85°C), and seam straightness (via integrated vision systems). When producing our heavy-duty travel bags, the system detected that thread tension variations were causing inconsistent seam strength. The real-time analysis identified that specific thread spools from a particular supplier were causing the issue, enabling immediate supplier coordination before 1,200 units were affected. The system has improved our first-pass seam quality from 78% to 96% and reduced sewing-related customer returns by 82% through continuous parameter optimization.

How does IoT ensure proper component assembly?

Automated component verification uses IoT sensors to validate that all bag components meet specifications before and during assembly. Our system uses RFID tags and weight sensors to verify that bag hardware components like zippers, buckles, and rivets are correct before assembly. When assembling our laptop messenger bags, the system detected that a recent batch of magnetic clasps had weaker than specified holding power. The IoT weight sensors identified the discrepancy during component preparation, preventing the installation of 800 substandard clasps. The system also monitors assembly sequence compliance, ensuring that complex bag constructions follow the proper order—particularly important for our technical backpack line with multiple compartments and padding layers. This verification has reduced assembly errors by 91% and improved product consistency across production batches.

What data integration and analysis approaches work best?

IoT systems generate substantial data that requires effective integration, processing, and analysis to deliver actionable insights. Traditional approaches often struggle with data silos, delayed analysis, and limited correlation capabilities that prevent manufacturers from fully leveraging IoT-generated information.

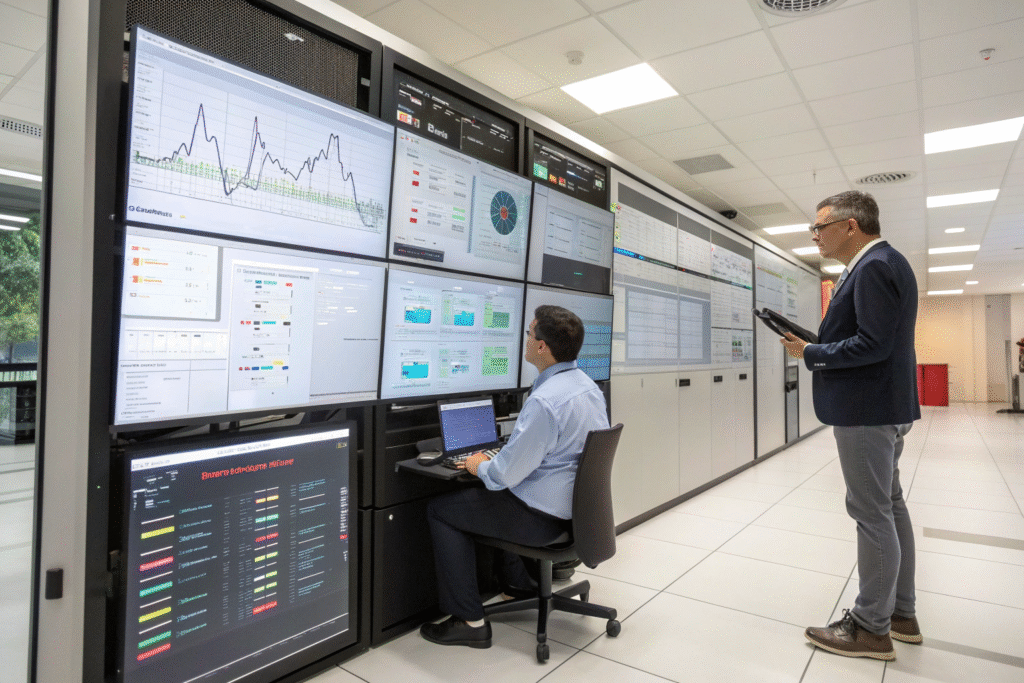

Effective data integration and analysis for bag production IoT involves cloud platforms, real-time analytics, predictive algorithms, and visualization tools that transform raw sensor data into actionable manufacturing intelligence. This comprehensive approach enables proactive decision-making and continuous process improvement.

How should IoT data be structured for actionable insights?

Unified data architecture ensures that information from diverse IoT sensors can be correlated and analyzed effectively. Our implementation uses a standardized data model that normalizes information from 47 different sensor types across our bag production facility. The system correlates equipment parameters with quality outcomes, identifying relationships that were previously invisible. The analysis revealed that specific vibration patterns in our folding machines for compact bags predicted 89% of handle attachment failures. By addressing these vibration issues proactively, we reduced handle-related defects by 76%. The data architecture also enables real-time alerting when parameter combinations indicate potential quality issues, such as the correlation between specific humidity levels and adhesive curing problems in our waterproof bag production.

What analytics approaches deliver the most value?

Predictive quality analytics uses machine learning to identify parameter patterns that precede quality issues or equipment failures. Our system analyzes historical parameter data against quality outcomes to build predictive models that flag potential issues before they affect production. When introducing a new vegan leather material for our ethical handbag line, the system identified that traditional temperature settings were causing seam weakness. The predictive model suggested a 7°C adjustment that improved seam strength by 43% while maintaining production speed. The analytics also optimize maintenance schedules based on actual equipment usage rather than fixed intervals, reducing maintenance costs by 28% while improving equipment reliability. These advanced analytics have transformed our approach from reactive problem-solving to proactive quality assurance.

Conclusion

Implementing IoT for bag production parameter monitoring transforms manufacturing from experience-based estimation to data-driven precision across all production stages. By deploying comprehensive sensor networks, integrating real-time data streams, and applying advanced analytics, bag manufacturers can maintain optimal production parameters, prevent quality issues, and maximize operational efficiency. The most successful implementations combine technological sophistication with practical manufacturing knowledge, creating systems that not only monitor parameters but also provide actionable insights for continuous process improvement. As bag designs continue to evolve with new materials, constructions, and customer expectations, IoT parameter monitoring provides the foundation for consistent quality, efficient production, and competitive advantage in the dynamic fashion accessories market.

If you're considering implementing IoT for parameter monitoring in your bag production operations, we invite you to contact our Business Director, Elaine. She can discuss how our IoT manufacturing expertise and technological capabilities can help you achieve your quality and efficiency goals. Reach her at: elaine@fumaoclothing.com.