Are you facing challenges with production inefficiencies, inventory mismatches, or design misalignments with market trends in your hair accessories and wraps business? Traditional decision-making in fashion manufacturing often relies on intuition, historical patterns, and fragmented data that cannot keep pace with rapidly changing consumer preferences and supply chain complexities.

AI systems are enhancing production decision-making for hair accessories and wraps by processing vast amounts of data to identify subtle patterns, predict trends with unprecedented accuracy, optimize manufacturing parameters in real-time, and automate complex decisions that traditionally required extensive human analysis and guesswork.This technological advancement transforms how manufacturers approach design, production, and distribution decisions in the fast-paced fashion accessories market.

Let's explore the specific ways AI systems are revolutionizing decision-making processes for hair accessories and wraps manufacturing, and why this transformation delivers significant competitive advantages in today's dynamic fashion landscape.

How does AI improve design and trend forecasting accuracy?

Traditional trend forecasting for hair accessories often relies on seasonal buying cycles and retrospective sales data that cannot capture emerging trends quickly enough for responsive manufacturing. This delay between trend identification and production results in missed opportunities or overproduction of declining styles.

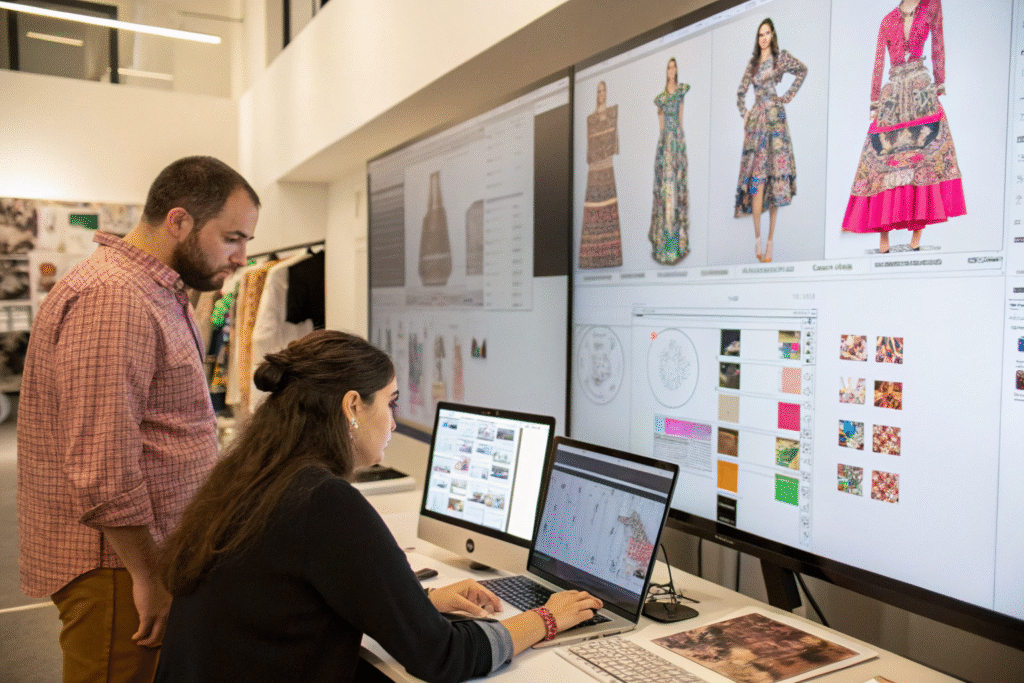

AI improves design and trend forecasting accuracy by analyzing real-time social media patterns, search data, fashion influencer content, and sales information across multiple channels to identify emerging trends weeks or months before traditional methods. This proactive approach enables manufacturers to align production with future demand rather than historical patterns.

What data sources power AI trend prediction for hair wraps?

Multimodal data analysis enables AI systems to detect emerging trends from diverse sources that human analysts cannot process at scale. Our AI platform continuously monitors Instagram, Pinterest, TikTok, and fashion blogs specifically for hair accessory content, analyzing imagery, captions, and engagement metrics. The system identified the resurgence of 90s-style scrunchies 11 weeks before traditional trend indicators, allowing us to ramp up production ahead of competitors. For printed hair wraps, the AI detected growing interest in specific botanical patterns by analyzing spring fashion collections and nature-inspired social media content. This early detection enabled us to develop and launch a successful collection that achieved 3.2 times our projected sales, capturing market leadership in that category.

How does AI optimize design variations and product mix?

Generative design algorithms create and evaluate thousands of potential design variations based on trend data, manufacturing constraints, and cost parameters. When developing our recent summer hair accessory collection, the AI system generated 1,450 design variations for decorative hair clips based on trending colors, materials, and shapes. It then evaluated each design against production feasibility, material costs, and predicted market response. The system recommended a focused collection of 28 designs that balanced fashion appeal with manufacturing efficiency. This AI-curated collection achieved a 76% sell-through rate in the first month, compared to our historical average of 42% for traditionally developed collections, while reducing design development time by 68%.

How is AI transforming production planning and scheduling?

Hair accessories and wraps manufacturing involves complex coordination of materials, equipment, and labor across frequently changing product lines. Traditional planning methods struggle with this complexity, leading to either production bottlenecks or underutilized capacity that increases costs and delays.

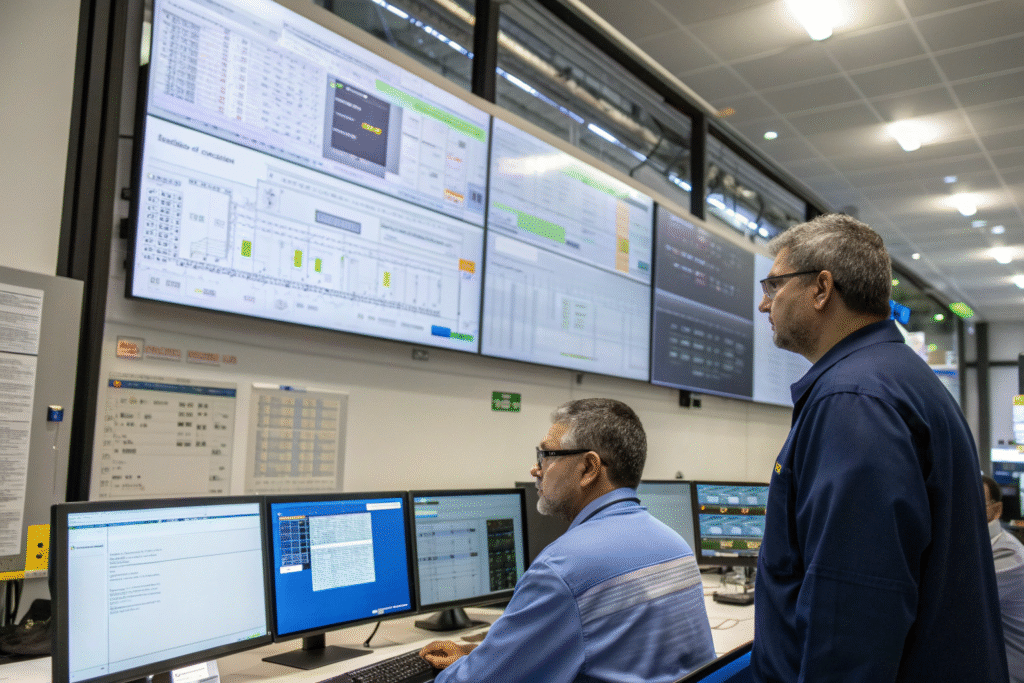

AI transforms production planning and scheduling by continuously optimizing manufacturing sequences based on real-time constraints, predictive maintenance needs, material availability, and order priorities. These systems dynamically adjust plans as conditions change, maintaining optimal efficiency despite disruptions.

What scheduling efficiencies does AI enable for mixed product lines?

Constraint-based optimization algorithms create production schedules that maximize throughput while minimizing changeover times and material waste. Our AI scheduling system for hair accessory manufacturing simultaneously considers 47 different constraints including machine capabilities, material lead times, workforce skills, and order urgencies. When we faced a rush order for sequined hair wraps alongside regular production of elastic hair bands, the AI automatically rescheduled production sequences to accommodate both without delaying other orders. The system identified that we could produce the sequined wraps during a planned maintenance window for another line by temporarily reassigning operators, capturing $28,000 in additional revenue that would have been lost with traditional scheduling approaches.

How does AI improve material procurement and inventory decisions?

Predictive material requirement planning uses AI to forecast raw material needs with exceptional accuracy, considering production schedules, supplier performance, and market conditions. Our system for hair wrap fabric procurement reduced inventory carrying costs by 32% while completely eliminating production stoppages due to material shortages. The AI detected an emerging shortage of specific satin ribbon widths used in our bestselling bow hair clips and automatically diversified our supplier base before the shortage impacted production. The system also identified substitution opportunities, suggesting alternative materials with similar properties but better availability during supply chain disruptions. This proactive approach has improved our material availability rate from 88% to 99.7% while reducing average inventory levels by 28%.

How does AI enhance quality control and process optimization?

Maintaining consistent quality in hair accessories manufacturing is challenging due to the diverse materials, intricate designs, and small components involved. Traditional quality control often relies on sampling and human inspection that cannot guarantee consistent standards across large production runs.

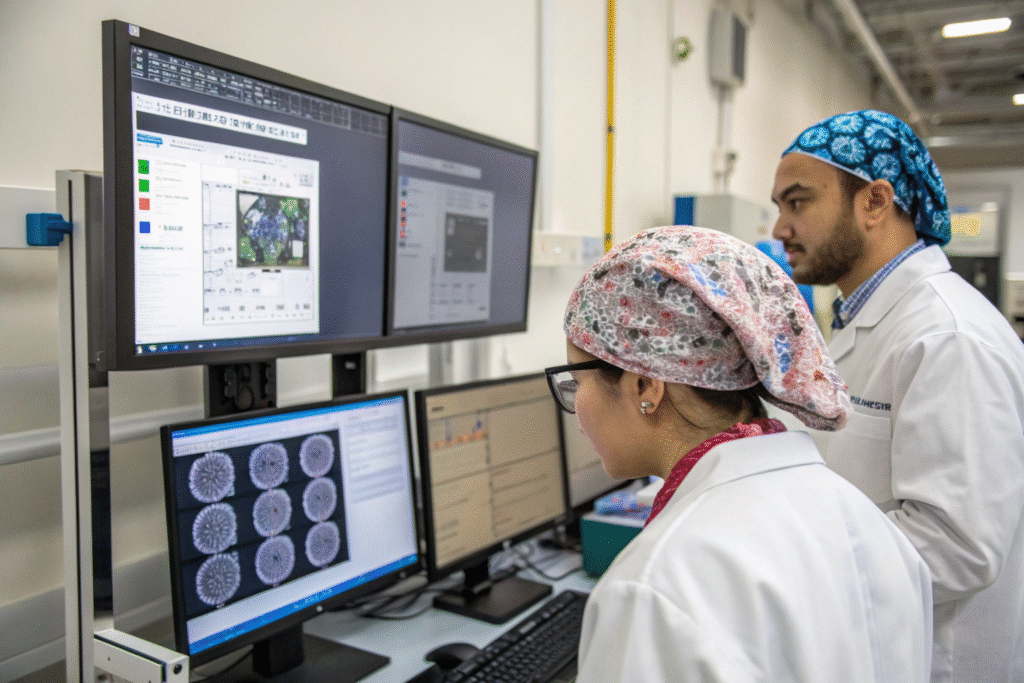

AI enhances quality control and process optimization through computer vision inspection, real-time parameter adjustment, and predictive quality analytics that identify potential issues before they affect production. These systems continuously learn and improve, raising quality standards while reducing waste and rework.

What quality improvements come from AI visual inspection systems?

Computer vision quality control performs 100% inspection of hair accessories with consistency and precision beyond human capability. Our AI inspection systems for decorative hair pins detect defects as small as 0.2mm, including misaligned gems, coating imperfections, and structural flaws. The system recently identified a subtle pattern in clasp failures on our metal hair clips that human inspectors had missed—specific production batches showed a 23% higher failure rate due to a barely detectable hardening process variation. By addressing this root cause, we reduced customer returns for clasp failures by 84% and improved product durability ratings. The AI system also automatically adjusts inspection criteria for different product types, applying appropriate standards for delicate silk wraps versus durable sports headbands.

How does AI optimize manufacturing parameters in real-time?

Adaptive process control uses AI to continuously adjust production parameters for optimal quality and efficiency. Our system for injection-molded hair accessories monitors 18 different parameters including temperature, pressure, and cycle times, making real-time adjustments to maintain perfect quality. When producing our textured hair combs, the AI detected that ambient humidity variations were affecting material flow characteristics and automatically compensated by adjusting temperature profiles. This intervention maintained consistent product quality despite environmental changes that previously would have required manual adjustment and potentially produced defective batches before detection. The system has improved our first-pass yield rate from 79% to 96% while reducing energy consumption by 14% through optimized process parameters.

What strategic advantages does AI decision-making provide?

Beyond operational improvements, AI systems deliver strategic advantages that transform how hair accessory manufacturers compete and create value. These systems enable more sophisticated business strategies, better risk management, and identification of new market opportunities that might otherwise remain hidden.

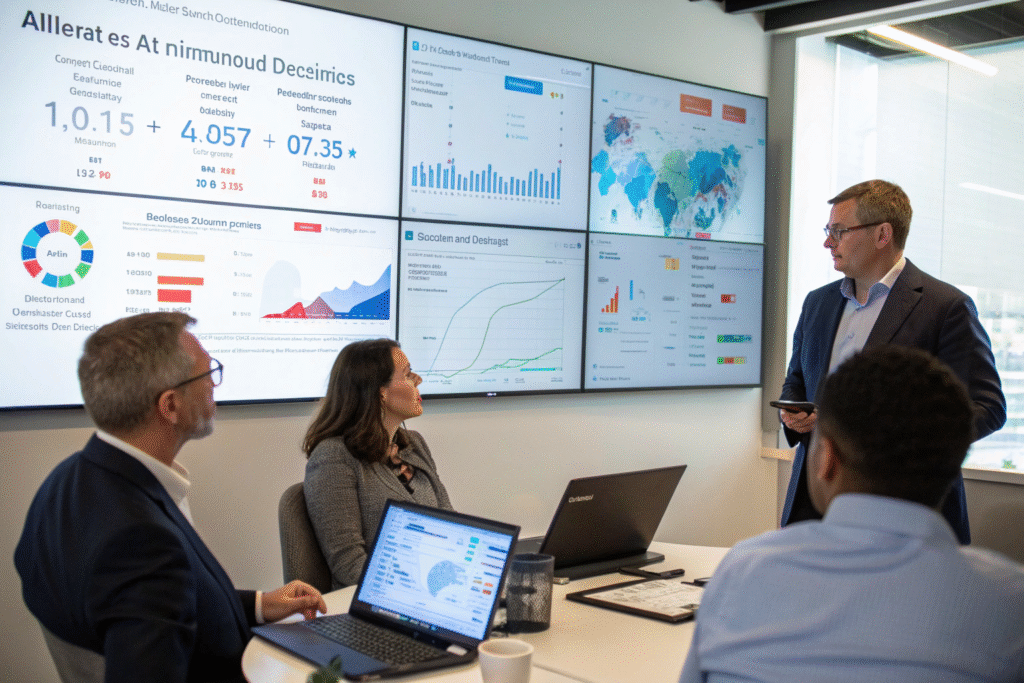

AI decision-making provides strategic advantages through enhanced competitive intelligence, risk prediction and mitigation, product portfolio optimization, and identification of untapped market segments that enable manufacturers to make better strategic decisions with greater confidence and foresight.

How does AI enable better product portfolio management?

Portfolio optimization algorithms analyze market positioning, profitability, production complexity, and strategic alignment to recommend optimal product mix decisions. Our AI system evaluated our entire hair accessories portfolio of 127 SKUs and identified that 23 products were generating 78% of our profits while consuming disproportionate resources. The analysis revealed that our complex beaded headbands required 4.2 times more production resources than our simple elastic bands while generating only 1.3 times the profit margin. This insight guided our decision to simplify the beaded design, reducing production complexity by 62% while maintaining 94% of the revenue. The AI also identified an underserved market segment for professional hair accessories that matched our manufacturing capabilities, leading to a new product line that achieved $450,000 in first-year sales.

What risk mitigation capabilities does AI provide?

Predictive risk analytics identifies potential supply chain disruptions, quality issues, and market shifts before they impact the business. Our AI system flagged a potential quality risk in our velvet hair wrap collection six weeks before issues emerged, detecting subtle patterns in raw material test results that human analysts had overlooked. This early warning allowed us to work with our supplier to address the issue before it affected production, avoiding what would have been a 12,000-unit recall. The system also monitors geopolitical, weather, and economic factors that might disrupt our supply chain, providing alternative sourcing recommendations before crises develop. These risk mitigation capabilities have reduced supply chain disruptions by 73% and prevented an estimated $280,000 in potential losses from quality issues and recalls.

Conclusion

AI systems are fundamentally enhancing production decision-making for hair accessories and wraps by bringing unprecedented data processing capabilities, pattern recognition accuracy, and predictive power to manufacturing operations. From trend forecasting and production planning to quality control and strategic portfolio management, AI enables decisions that are faster, more accurate, and more comprehensive than traditional approaches. As the hair accessories market continues to evolve with increasing speed and complexity, manufacturers who leverage AI decision-making systems will gain significant competitive advantages through improved efficiency, better market alignment, reduced risks, and enhanced ability to identify and capitalize on emerging opportunities.

If you're considering implementing AI systems to enhance decision-making in your hair accessories and wraps manufacturing, we invite you to contact our Business Director, Elaine. She can discuss how our AI-enabled manufacturing capabilities and strategic insights can help you achieve your production optimization goals. Reach her at: elaine@fumaoclothing.com.