Are you struggling with production inefficiencies, quality inconsistencies, or inability to meet fast-changing market demands in your hat manufacturing operations? Traditional hat manufacturing faces unique challenges with diverse materials, seasonal demand fluctuations, and intricate assembly processes that often resist optimization through conventional methods.

Hat manufacturers can implement the smart factory concept by integrating IoT sensors, data analytics, automated material handling, and connected production systems that work together to create an adaptive, efficient, and transparent manufacturing environment specifically optimized for headwear production. This transformation enables manufacturers to respond dynamically to fashion trends while maintaining quality and reducing costs across baseball caps, beanies, sun hats, and other headwear categories.

Let's explore the practical implementation steps that hat manufacturers can take to transition from traditional operations to smart factory systems and the specific technologies that deliver the greatest impact for headwear production.

What foundational technologies enable smart hat manufacturing?

Traditional hat factories often operate with disconnected equipment and manual processes that create information silos and limit visibility across production stages. This disconnected approach prevents the holistic optimization needed for efficient headwear manufacturing.

Foundational technologies enabling smart hat manufacturing include industrial IoT platforms, cloud computing infrastructure, connected machinery with open communication protocols, and centralized data management systems that collectively create the digital backbone for smart operations. These technologies transform isolated equipment into interconnected production systems.

How do IoT sensors transform hat production monitoring?

Industrial IoT sensors installed on hat manufacturing equipment provide continuous, real-time monitoring of production parameters that were previously unmeasured or manually recorded. In our baseball cap production line, we've installed sensors that monitor sewing machine speed, stitch consistency, and needle temperature. For knit beanie manufacturing, sensors track yarn tension, knitting speed, and pattern consistency. This data streams to our central platform where algorithms detect anomalies and predict maintenance needs. The system recently identified a 12% variation in embroidery thread tension that was causing inconsistent logo application on caps—an issue that previously went undetected until quality inspection, by which time hundreds of defective units had been produced.

What communication protocols integrate diverse hat-making equipment?

Unified communication protocols like OPC UA and MTConnect enable different hat manufacturing equipment to share data seamlessly. Our implementation connected legacy brim molding machines with new automated sewing systems and material handling equipment, creating a continuous data flow from raw material to finished hat. This integration allowed us to identify that specific humidity levels in our straw hat production area were causing material brittleness that increased breakage during weaving. By automatically adjusting environmental controls based on real-time material condition data, we reduced material waste by 23% and improved production speed by 17% for our summer hat collections.

How to implement data-driven production planning for headwear?

Hat manufacturers face particular challenges with seasonal demand spikes, fashion trend volatility, and material lead time variations that complicate production planning. Traditional forecasting methods often result in either stockouts or overproduction, especially for trend-sensitive items.

Implementing data-driven production planning for headwear involves integrating sales data, trend analytics, material availability information, and production capacity data to create adaptive production schedules that respond to real-time market signals. This approach transforms planning from guesswork to science.

What data sources improve hat demand forecasting?

Multi-source demand intelligence combines historical sales data, social media trend indicators, weather pattern analysis, and retail inventory data to create more accurate production forecasts. Our system analyzes Instagram and Pinterest engagement with specific hat styles—like the recent surge in bucket hat popularity—to adjust production volumes before traditional sales data signals the trend. For seasonal items like winter beanies, we incorporate weather forecasts and regional temperature data to optimize distribution timing and quantities. This approach has improved our forecast accuracy by 38% and reduced end-of-season markdowns by 52% compared to our previous historical sales-based forecasting method.

How can dynamic scheduling optimize hat factory utilization?

AI-powered dynamic scheduling continuously optimizes production sequences based on real-time factory conditions, order priorities, and material availability. Our system automatically reschedules production when unexpected events occur, such as rush orders for custom team caps or material delays for specialty sun hat components. The algorithm considers machine capabilities, setup times, and workforce availability to create optimal production sequences. When a major retailer requested 5,000 emergency units of a trending baseball cap style, our system automatically identified available capacity, resequenced existing orders with minimal disruption, and enabled us to fulfill the request in 7 days instead of the typical 21-day lead time, dramatically strengthening our relationship with that client.

What automation technologies specifically benefit hat manufacturing?

Hat manufacturing involves specialized processes like brim forming, crown shaping, and intricate embroidery that present unique automation challenges. Manual operations in these areas create consistency issues and limit production scalability, especially for complex designs.

Automation technologies specifically benefiting hat manufacturing include robotic sewing systems, computer-controlled embroidery, automated material handling, and vision-guided assembly that address the precise requirements of headwear production while maintaining the quality standards demanded by fashion markets.

How does robotic sewing improve hat quality consistency?

Automated sewing systems with computer vision guidance have transformed our ability to produce consistent, high-quality headwear. Our robotic sewing cells for baseball cap assembly maintain perfect stitch length, tension, and seam alignment throughout production runs of any size. The systems use cameras to detect fabric grain and pattern alignment, automatically adjusting material placement to ensure symmetrical results. This technology has been particularly valuable for our structured cap production, where consistent seam quality is essential for maintaining the intended shape. Since implementation, we've reduced sewing defects by 76% and increased production speed by 45% while actually improving quality scores from our most demanding clients.

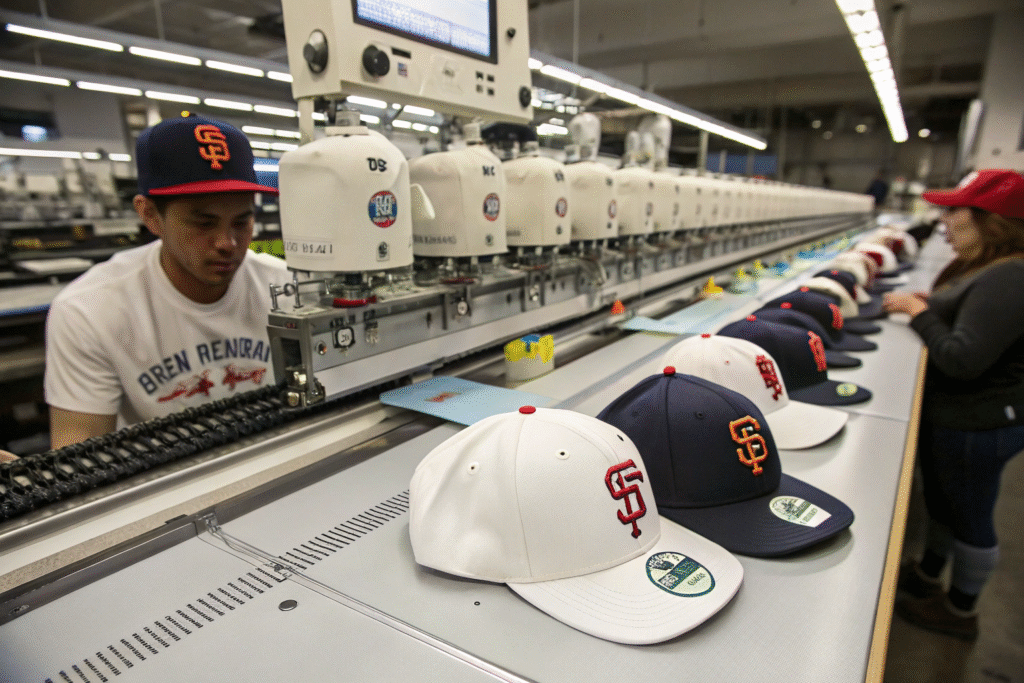

What role does automated embroidery play in custom hat production?

Computer-controlled embroidery systems with automatic thread management and pattern optimization have revolutionized our custom hat capabilities. Our smart embroidery cells can switch between 12 colors automatically, detect thread breaks instantly, and optimize stitch patterns for different materials without manual intervention. When producing custom logo caps for corporate clients, the system automatically adjusts stitch density and direction based on the specific material—whether it's wool, cotton, or performance fabric. This intelligence has reduced our embroidery setup time by 80% and eliminated the material waste previously caused by test runs. The system's ability to store thousands of designs and recall them instantly has also made small-batch custom orders economically viable.

How to implement quality management 4.0 in hat production?

Hat quality involves both aesthetic elements and functional requirements that traditional sampling-based inspection often misses. Visual defects, dimensional variations, and material inconsistencies can escape detection until products reach customers, creating returns and brand reputation damage.

Implementing quality management 4.0 in hat production involves deploying inline inspection systems, establishing digital quality gates, implementing statistical process control with real-time feedback, and creating closed-loop correction systems that prevent defects rather than simply detecting them.

How do computer vision systems enhance hat inspection?

AI-powered visual inspection systems perform 100% quality checking of hats at multiple production stages with consistency impossible for human inspectors. Our systems examine cap brims for curvature consistency, check embroidery for thread coverage and alignment, verify logo placement accuracy, and detect fabric flaws or color variations. For beanie production, the systems inspect knitting consistency, pom-pom attachment security, and size dimensions. The most significant impact has been in identifying subtle defects that human inspectors routinely miss—like slight color variations between different production batches of the same baseball cap style. This comprehensive inspection has reduced customer returns by 64% and improved our first-pass quality rate from 87% to 98.5%.

What is the role of digital twins in hat quality management?

Digital twin technology creates virtual replicas of our hat manufacturing processes that we use to simulate production, predict quality outcomes, and optimize parameters before physical production begins. We've developed digital twins for our brim molding process that accurately predict material behavior under different temperature and pressure conditions. This capability allowed us to reduce material trial waste by 92% when introducing new recycled materials for our eco-friendly cap line. The digital twins also help us validate quality control parameters for new hat designs, ensuring that our inspection systems are calibrated to detect the specific defect types most likely to occur with each unique construction method and material combination.

Conclusion

Implementing the smart factory concept in hat manufacturing delivers transformative improvements in efficiency, quality, flexibility, and cost management through the strategic integration of connected technologies, data analytics, and automated systems. By building on foundational IoT infrastructure, adopting data-driven planning, implementing specialized automation, and embracing Quality 4.0 principles, hat manufacturers can successfully transition to smart operations that compete effectively in today's fast-paced fashion market. The journey requires careful planning and phased implementation, but the results justify the investment through significant competitive advantages and enhanced customer satisfaction.

If you're ready to explore smart factory implementation for your hat manufacturing operations, we invite you to contact our Business Director, Elaine. She can discuss how our experience with headwear manufacturing technology can help you develop a tailored implementation strategy. Reach her at: elaine@fumaoclothing.com.