Are you tired of manufacturing inconsistencies and quality issues in your accessory production? Traditional manufacturing methods often struggle with maintaining consistent quality across large orders and adapting to rapid design changes. These challenges can impact your brand reputation and bottom line.

AI-enhanced accessory manufacturing combines artificial intelligence with advanced production technologies to create smarter, more efficient, and highly adaptive manufacturing processes that deliver superior quality products with unprecedented efficiency.This revolutionary approach transforms how accessories like hair clips, belts, and scarves are designed, produced, and quality-checked, offering significant advantages over conventional methods.

Let's explore the key features that make AI-enhanced manufacturing a game-changer for fashion accessory production.

How does AI improve quality control in accessory production?

Manual quality inspection can miss subtle defects, leading to customer complaints and returns. Even experienced quality controllers can suffer from fatigue and inconsistency, especially during high-volume production runs.

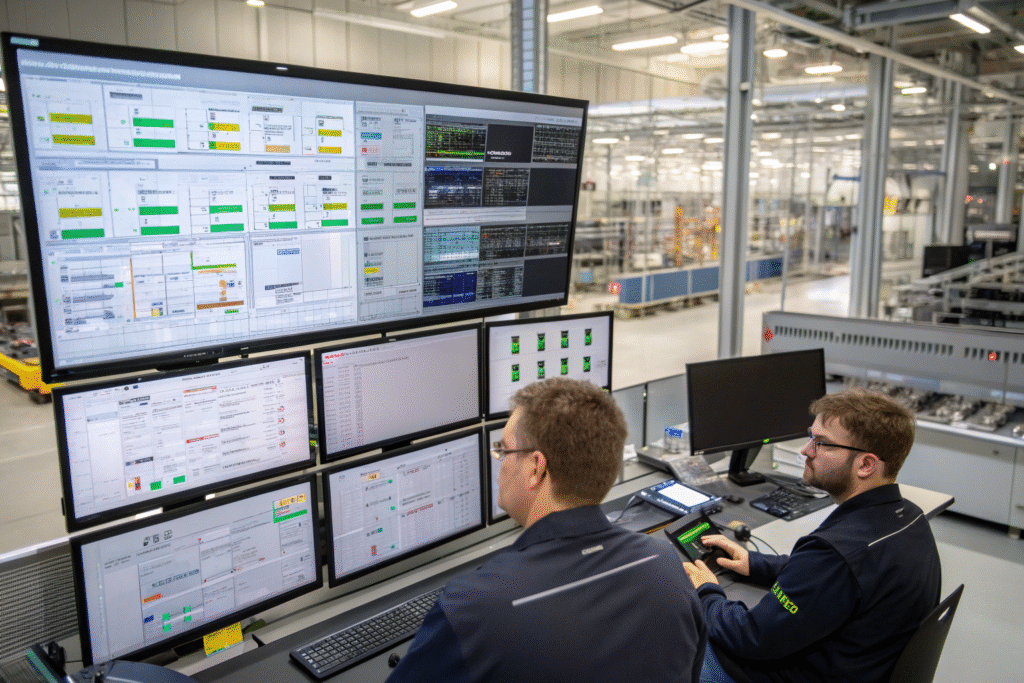

AI revolutionizes quality control through computer vision systems that inspect every product with microscopic precision, machine learning algorithms that continuously improve detection accuracy, and predictive analytics that identify potential quality issues before they occur. This comprehensive approach ensures consistent excellence across all production batches.

What makes AI visual inspection superior to human checking?

Our AI visual inspection systems utilize high-resolution cameras and sophisticated algorithms to examine every detail of each accessory. Unlike human inspectors who can only sample check products, our systems perform 100% inspection of every hair clip, belt buckle, and scarf that passes through production lines. The AI detects imperfections as small as 0.05mm - including color variations, stitching errors, and material flaws - with consistent accuracy unaffected by fatigue or subjective judgment. This comprehensive inspection capability significantly reduces the risk of defective products reaching your customers.

How do machine learning algorithms predict quality issues?

Machine learning algorithms in our manufacturing process analyze historical quality data to identify patterns and predict potential defects before they occur. For scarves and woven accessories, the system monitors loom performance and yarn quality, alerting operators to emerging issues. The algorithms continuously learn from new data, improving their predictive accuracy over time. This proactive approach allows us to address quality concerns during production rather than after completion, saving both time and materials while ensuring higher overall quality standards.

Can AI optimize production planning and efficiency?

Traditional production planning often relies on estimates and historical patterns, leading to either overproduction or stockouts. This inefficiency can result in increased costs and missed market opportunities.

AI dramatically enhances production planning and efficiency through demand forecasting, real-time production optimization, and intelligent resource allocation. These systems analyze multiple data points to create more accurate production schedules and identify efficiency improvements humans might miss.

How does AI demand forecasting reduce inventory waste?

Our AI demand forecasting systems analyze market trends, seasonal patterns, and sales data to predict optimal production quantities for each accessory type. For items like seasonal baseball caps or holiday-themed hair accessories, the AI considers factors like weather patterns, social media trends, and historical sales performance. This precise forecasting minimizes overproduction of slow-moving items while ensuring adequate stock of popular products. The result is significantly reduced inventory costs and less dead stock, creating a more sustainable and profitable production model.

What role does real-time production optimization play?

Real-time production optimization uses AI to monitor and adjust manufacturing parameters continuously during operation. In our gloves and knit accessories production, the system automatically adjusts machine speeds, tension settings, and material feed rates based on real-time quality data and efficiency metrics. This dynamic optimization ensures consistent quality while maximizing output. The AI can also identify bottlenecks and suggest workflow improvements, increasing overall equipment effectiveness by up to 25% compared to traditional manufacturing approaches.

How does AI enhance customization capabilities?

Today's consumers increasingly demand personalized products, but traditional manufacturing struggles with custom orders due to setup costs and production complexity. This limitation can prevent brands from offering the customization options their customers want.

AI enables mass customization by automating design adaptation, optimizing production workflows for small batches, and ensuring consistent quality across customized products. This capability allows manufacturers to offer personalization at scale without sacrificing efficiency or quality.

How does AI facilitate design adaptation for custom orders?

Our AI design adaptation systems can automatically modify base designs to accommodate custom requirements while maintaining structural integrity and production feasibility. For customized hair bands or personalized belts, the AI suggests optimal placement for logos, text, or decorative elements based on material properties and manufacturing constraints. The system can generate production-ready files within minutes, eliminating the need for manual redesign and significantly reducing the time from concept to production for custom orders.

What makes AI-driven small batch production efficient?

AI-driven small batch production optimizes manufacturing parameters specifically for limited runs of customized accessories. The system automatically calculates the most efficient material usage, tool paths, and production sequences for each unique order. For personalized cups or limited edition scarves, this means we can produce small quantities cost-effectively while maintaining the same quality standards as large production runs. This capability opens new business opportunities for brands wanting to offer exclusive or personalized products without the traditional cost penalties of small-scale manufacturing.

Does AI improve sustainability in accessory manufacturing?

The fashion industry faces increasing pressure to adopt sustainable practices, but identifying and implementing effective sustainability measures can be challenging within traditional manufacturing frameworks.

AI significantly enhances manufacturing sustainability through optimized material usage, reduced energy consumption, and waste minimization. These intelligent systems identify opportunities for environmental improvement that might otherwise go unnoticed, creating both ecological and economic benefits.

How does AI optimize material usage and reduce waste?

Our AI material optimization systems analyze design patterns and production requirements to minimize waste throughout the manufacturing process. For leather belts and fabric accessories, the AI calculates cutting patterns that maximize material utilization, reducing scrap by up to 30% compared to traditional methods. The system also suggests alternative materials or design modifications that maintain quality while using less resources. This intelligent approach not only reduces environmental impact but also lowers material costs, creating a clear business case for sustainable practices.

What energy management capabilities does AI provide?

AI energy management continuously monitors and optimizes power consumption across all manufacturing equipment. The system learns production patterns and automatically adjusts energy usage during non-peak periods. For energy-intensive processes like plastic injection molding for hair clips or metal working for buckles, the AI identifies opportunities to reduce power consumption without affecting quality or output. These optimizations typically reduce energy costs by 15-25% while significantly decreasing the carbon footprint of accessory production.

Conclusion

AI-enhanced accessory manufacturing represents a significant leap forward in production technology, offering improved quality control, optimized efficiency, enhanced customization, and superior sustainability. These features combine to create a manufacturing environment that is not only more intelligent and efficient but also more responsive to market demands and environmental responsibilities.

If you're interested in leveraging AI-enhanced manufacturing for your accessory lines, we invite you to contact our Business Director, Elaine. She can discuss how our advanced AI capabilities can benefit your specific product requirements. Reach her at: elaine@fumaoclothing.com.