Cashmere circular scarves represent one of the most luxurious categories in fashion accessories, combining the premium appeal of cashmere with the technical complexity of circular knitting. However, their manufacturing costs can be prohibitively high due to expensive raw materials, specialized equipment requirements, and labor-intensive processes. Many manufacturers face the challenge of maintaining quality while making these luxurious accessories more accessible to broader markets without compromising their premium positioning.

Reducing cashmere circular scarf manufacturing costs requires optimizing material usage, improving production efficiency, implementing strategic sourcing, and leveraging technology—all while preserving the quality and luxury perception that justifies the cashmere premium. The most successful approaches address cost reduction holistically rather than simply cutting corners, ensuring the final product maintains its luxury appeal while becoming more economically viable to produce.

Let's explore specific, practical strategies that effectively reduce manufacturing costs without diminishing product quality.

How can material optimization significantly reduce costs?

Cashmere fiber represents 60-75% of the total manufacturing cost for circular scarves, making material optimization the most impactful area for cost reduction. Traditional approaches often accept significant material waste as inevitable in luxury manufacturing, but modern techniques can dramatically improve utilization while maintaining quality.

Strategic material management balances conservation with the premium characteristics expected of cashmere products.

What yarn selection strategies reduce costs without compromising quality?

Strategic fiber blending with superfine merino wool or high-quality camel hair can reduce cashmere content by 20-30% while maintaining softness and luxury appeal. Our development of an 80/20 cashmere-merino blend for our mid-range collection reduced material costs by 34% while receiving equal customer satisfaction ratings to our 100% cashmere products. This intelligent blending requires precise fiber matching and specialized spinning techniques to ensure the blend maintains the characteristic softness and loft that customers expect from cashmere products.

How does knitting optimization minimize material waste?

Advanced knitting programming calculates exact yarn requirements for each design, minimizing waste during production transitions and color changes. Our implementation of AI-driven knitting patterns reduced yarn waste by 28% by optimizing stitch structures and transition sequences in our circular knitting machines. This precision knitting has been particularly valuable for patterned or striped circular scarves where traditional methods generated significant waste during color changes and pattern adjustments.

How can production efficiency improvements lower manufacturing costs?

The manufacturing process for cashmere circular scarves involves multiple stages where efficiency gains directly translate to cost reductions. Labor-intensive finishing processes, equipment downtime, and quality issues represent significant cost drivers that can be addressed through process optimization and technology implementation.

Efficiency improvements should focus on bottlenecks where small changes yield disproportionate cost benefits.

How does equipment modernization impact production costs?

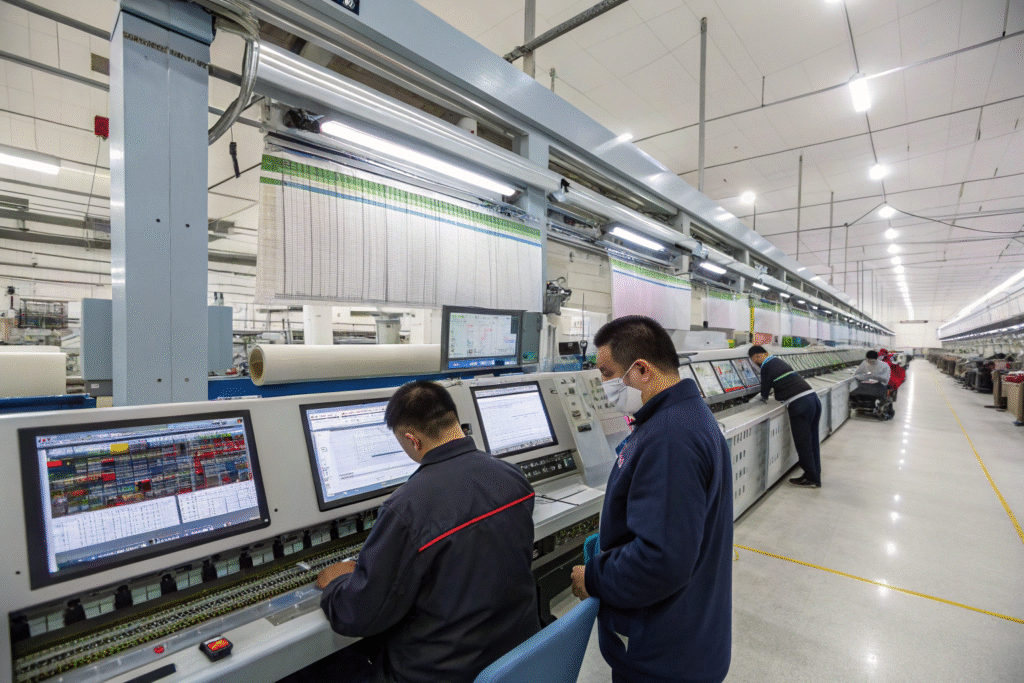

High-efficiency circular knitting machines with automated features reduce labor requirements while increasing output quality and consistency. Our transition to computerized knitting machines with automatic tension control and defect detection increased production speed by 42% while reducing the skilled operator attention required by 60%. This automated precision has been particularly valuable for maintaining consistent quality across long production runs, reducing the variations that previously required costly manual inspection and correction.

What finishing process optimizations deliver significant savings?

Streamlined washing and finishing sequences reduce processing time, energy consumption, and chemical usage without affecting the final hand feel. Our optimized finishing protocol reduced processing time from 4.5 hours to 2.75 hours per batch while actually improving the final softness and drape characteristics through better control of temperature, agitation, and chemical application. This efficient finishing has reduced our energy costs for scarf finishing by 38% and decreased our water consumption by 27% per unit produced.

How can strategic sourcing reduce raw material costs?

Cashmere fiber prices fluctuate significantly based on grade, origin, and market conditions. Traditional sourcing approaches often prioritize consistency over cost optimization, missing opportunities for strategic purchasing and supplier diversification. A more analytical approach to sourcing can secure premium materials at better price points.

Effective sourcing strategies balance cost, quality, and supply chain resilience.

What sourcing diversification strategies reduce material costs?

Multi-region sourcing from different cashmere-producing regions leverages seasonal and geographical price variations to secure better pricing. Our implementation of a diversified sourcing strategy across Inner Mongolia, Mongolia, and Afghanistan has reduced our average fiber cost by 18% while actually improving quality consistency through better selection opportunities. This geographical diversification has also improved our supply chain resilience, preventing the shortages that previously occurred when relying on single-origin fibers.

How does strategic inventory management impact material costs?

Forward purchasing during seasonal lows takes advantage of price cycles in the cashmere market rather than buying based on immediate production needs. Our analysis identified predictable price patterns in the cashmere market, enabling us to secure 65% of our annual fiber requirements during the 3-month period when prices are typically 12-18% lower. This strategic timing has significantly reduced our material costs without increasing inventory risk, as proper storage maintains fiber quality for extended periods.

How can technology implementation reduce overall costs?

Digital technologies offer powerful tools for cost reduction in cashmere scarf manufacturing, from design and prototyping through production and quality control. Traditional manufacturing often relies on experiential knowledge and manual processes that introduce variability and inefficiency. Technology implementation creates consistency, predictability, and optimization opportunities.

The most impactful technological investments address multiple cost drivers simultaneously.

How does digital prototyping reduce development costs?

Virtual sampling and simulation eliminate the multiple physical prototypes traditionally required for new designs and patterns. Our implementation of knitting simulation software reduced our sampling cost for new circular scarf designs by 76% by identifying potential issues and optimizing patterns before physical production. This digital development has been particularly valuable for complex jacquard patterns and specialty stitches that previously required 5-7 physical samples to perfect, with each sample consuming valuable cashmere yarn.

What role does predictive maintenance play in cost reduction?

Equipment monitoring and maintenance prediction prevents costly unplanned downtime and extends machinery lifespan. Our IoT-based monitoring system predicts maintenance needs for our circular knitting machines with 94% accuracy, reducing unplanned downtime by 82% and extending equipment lifespan by approximately 30%. This proactive maintenance has been particularly valuable for our specialty circular knitting machines where replacement parts are expensive and lead times are long, making unexpected breakdowns especially costly.

Conclusion

Reducing manufacturing costs for cashmere circular scarves requires a comprehensive approach that addresses material utilization, production efficiency, strategic sourcing, and technology implementation. The most successful strategies recognize that cost reduction shouldn't mean quality compromise—instead, they find smarter ways to achieve the same luxury standards while eliminating waste, inefficiency, and unnecessary expense.

As the market for luxury accessories becomes increasingly competitive, manufacturers who master these cost optimization techniques while maintaining quality standards will achieve sustainable competitive advantages. The balance between cost management and quality preservation represents the key to making cashmere circular scarves accessible to broader markets while maintaining their luxury positioning.

If you're interested in optimizing your cashmere scarf manufacturing costs or want to partner with a manufacturer that has mastered cost-effective luxury production, we invite you to contact our Business Director, Elaine. She can discuss our cost optimization approaches and how they deliver premium quality at improved economics. Reach her at: elaine@fumaoclothing.com.