Quality issues in fashion accessories manufacturing often remain undetected until final inspection or, worse, until products reach customers. Traditional quality control methods are inherently reactive, identifying defects after they occur rather than preventing them. This results in costly rework, material waste, delayed shipments, and potential damage to brand reputation. The complexity of accessory manufacturing—with diverse materials, intricate designs, and varied production techniques—makes consistent quality particularly challenging.

Fashion accessories factories can implement predictive quality analytics by integrating IoT sensors, computer vision systems, machine learning algorithms, and historical data analysis to identify patterns that precede defects and enable proactive intervention. This approach shifts quality management from detecting failures to predicting and preventing them, transforming quality from a cost center to a strategic advantage.

Let's explore the practical steps and technologies that enable accessories manufacturers to implement predictive quality analytics effectively across different product categories and production processes.

What infrastructure is needed for predictive quality analytics?

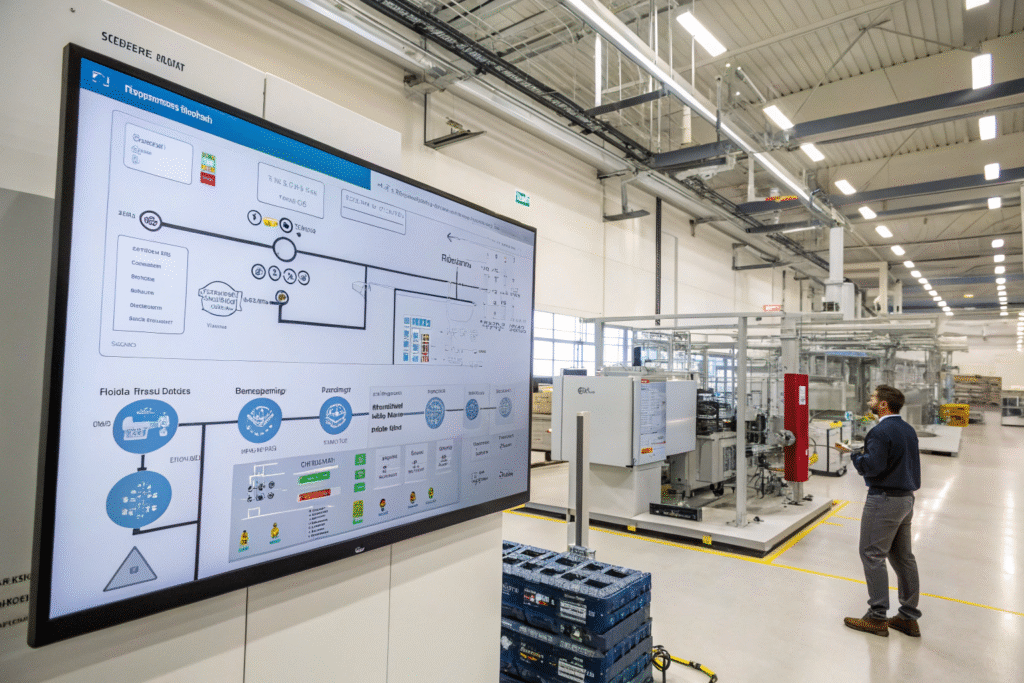

Implementing predictive quality analytics requires both technological infrastructure and organizational readiness. Many factories attempt to apply analytics to existing, fragmented data systems with limited success. A strategic approach builds the necessary foundation for data collection, integration, and analysis before deploying predictive models.

The infrastructure must capture comprehensive production data, process it effectively, and present actionable insights to the right personnel at the right time.

What data collection systems are essential for quality prediction?

IoT sensors installed on production equipment monitor operating parameters like temperature, pressure, speed, and vibration that influence quality outcomes. In our leather belt production, we installed 45 sensors across cutting, stitching, and finishing equipment to capture 128 different parameters that potentially affect quality. This comprehensive monitoring provides the raw data needed to identify correlations between process conditions and quality results that were previously invisible to human observation.

How do factories integrate disparate data sources for quality analytics?

Unified data platforms combine information from equipment sensors, quality inspection records, material certifications, and environmental conditions into a single analytical environment. Our implementation required integrating data from 7 different systems that previously operated independently, creating a holistic view of factors affecting accessory quality. This data integration revealed unexpected relationships—for example, how variations in workshop humidity affected glue curing time in our handbag assembly, explaining a previously mysterious quality inconsistency.

How can machine learning models predict quality issues?

Traditional statistical quality control identifies deviations from standards but struggles with complex, multi-variable quality relationships. Machine learning algorithms excel at detecting subtle patterns across numerous variables that human analysts or simpler statistical methods would miss.

The implementation of machine learning transforms quality management from rule-based to pattern-recognition based, enabling predictions rather than simple detection.

What types of machine learning algorithms are most effective for quality prediction?

Supervised learning models trained on historical quality data can predict defect probabilities based on current production conditions, while anomaly detection algorithms identify unusual patterns that may indicate emerging quality issues. Our implementation uses gradient boosting algorithms that analyze 47 production parameters to predict stitching quality in our bag production with 94% accuracy, 2-3 hours before defects become visible to human inspectors. This early warning capability has reduced stitching-related rework by 72% in our leather goods division.

How do computer vision systems enhance predictive quality capabilities?

Deep learning image analysis can detect subtle visual patterns that precede observable defects, such as material texture changes that indicate impending failure or color variations that suggest dyeing process issues. Our vision system for metal accessory inspection identifies microscopic surface irregularities that typically progress to visible defects after polishing, allowing intervention before value-added processes are wasted on ultimately defective components. This proactive defect prevention has been particularly valuable for our jewelry line where surface perfection is critical.

How can predictive analytics be applied to different accessory categories?

The diverse nature of fashion accessories—ranging from jewelry and belts to hats and bags—requires tailored approaches to predictive quality. A one-size-fits-all methodology would miss category-specific quality drivers and failure modes.

Successful implementation adapts the core predictive analytics framework to the specific materials, processes, and quality expectations of each accessory type.

How does predictive quality differ for metal versus textile accessories?

Material-specific quality parameters require different monitoring approaches—metal accessory quality depends heavily on finishing processes and alloy composition, while textile quality relates to weave consistency, dye penetration, and seam integrity. Our predictive system for metal belt buckles monitors plating bath chemistry, current density, and immersion time to predict coating adhesion issues, while our scarf quality prediction focuses on loom settings, yarn tension, and dyeing parameters. This category-specific modeling has improved our first-pass yield rate by 18% across diverse product lines.

What unique challenges does jewelry manufacturing present for predictive quality?

Miniature components and high-value materials make jewelry quality particularly consequential, while the precision required creates numerous potential failure points. Our predictive system for chain jewelry monitors 22 different parameters during forming, soldering, and polishing processes, identifying combinations that lead to weak links or surface imperfections. This precision manufacturing analytics has reduced customer returns for our gold and silver jewelry collections by 64% while significantly reducing the material waste associated with reworking precious metals.

How can factories operationalize predictive quality insights?

Collecting data and generating predictions provides limited value unless factories can translate insights into actionable interventions. The operationalization phase—closing the loop from prediction to prevention—represents the most challenging aspect of implementation.

Successful factories develop clear protocols, empowered teams, and integrated systems that ensure predictive insights drive tangible quality improvements.

How should factories structure response protocols for quality predictions?

Escalation workflows define specific actions for different prediction confidence levels and potential impact severity, while preventive action checklists guide operators through verified interventions. Our system uses a three-tier response protocol: automated parameter adjustments for high-confidence/low-impact predictions, operator alerts for medium-confidence issues, and process stoppage for high-confidence/high-impact predictions. This graded response system has prevented over 400 quality incidents in the past year while minimizing unnecessary production interruptions.

How does predictive quality integrate with existing quality management systems?

Complementary implementation enhances rather than replaces traditional quality control methods, with predictive analytics focusing on prevention while final inspection ensures verification. Our approach maintains sampling-based final inspection while adding predictive analytics for continuous process monitoring. This layered quality strategy has reduced our defect rate by 58% while actually decreasing total quality control costs by 31% through reduced rework and more efficient inspection targeting.

Conclusion

Implementing predictive quality analytics in fashion accessories factories represents a paradigm shift from reactive quality control to proactive quality assurance. By building the necessary infrastructure, applying appropriate machine learning techniques, adapting approaches to different product categories, and effectively operationalizing insights, manufacturers can dramatically reduce defects, waste, and costs while enhancing customer satisfaction.

The journey requires significant investment in technology, data infrastructure, and personnel training, but the returns—in both economic performance and competitive advantage—justify the commitment. As the technology continues to advance and become more accessible, predictive quality analytics will transition from cutting-edge capability to expected standard in progressive accessories manufacturing.

If you're interested in implementing predictive quality analytics in your accessory manufacturing or want to partner with a factory that has advanced quality prediction capabilities, we invite you to contact our Business Director, Elaine. She can discuss our quality analytics approach and how it delivers superior products through data-driven manufacturing. Reach her at: elaine@fumaoclothing.com.