The fashion accessories manufacturing sector is undergoing a profound digital transformation that's reshaping how products are designed, produced, and delivered. Traditional factories relying on manual processes, paper-based systems, and fragmented communication are increasingly unable to meet demands for speed, customization, and transparency. Digitalization is no longer a competitive advantage but a necessity for survival in an industry characterized by shortening product lifecycles and rising consumer expectations.

The key trends in fashion accessories factory digitalization include end-to-end digital integration, AI-driven optimization, additive manufacturing adoption, sustainable production technologies, and workforce digital upskilling.These interconnected trends are creating smarter, more responsive manufacturing ecosystems that balance efficiency with flexibility while addressing the industry's sustainability challenges.

Let's explore the specific digitalization trends that are transforming how accessories factories operate and compete in the global marketplace.

How is end-to-end digital integration transforming factory operations?

Traditional accessory manufacturing often suffers from information silos where design, production planning, manufacturing, and quality control operate as separate entities with limited communication. This fragmentation creates delays, errors, and inefficiencies that digital integration systematically eliminates.

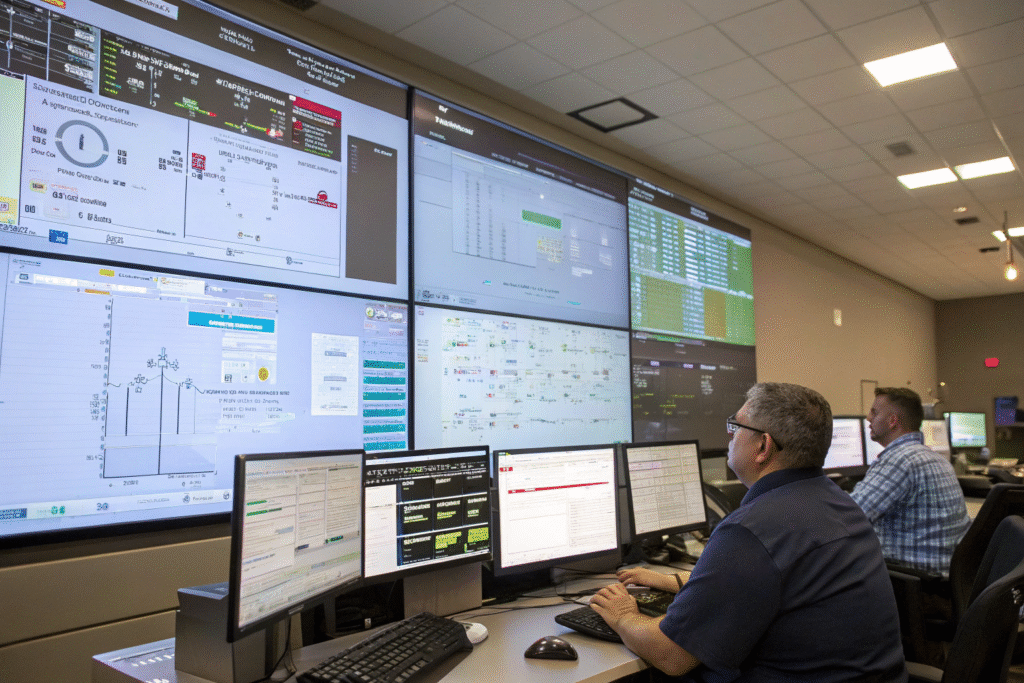

Digital thread technologies create seamless data flow across all factory functions, enabling real-time coordination and visibility from concept to customer delivery.

What role do Product Lifecycle Management (PLM) systems play in digital integration?

Unified digital platforms synchronize information across design, technical specifications, material sourcing, and production planning, creating a single source of truth for each product. Our implementation of an integrated PLM system reduced sample development time from 3 weeks to 5 days by eliminating the manual handoffs and version control issues that previously caused delays. This streamlined workflow has been particularly valuable for managing complex accessory collections with multiple components and customization options.

How does IoT connectivity enhance operational visibility?

Networked sensors and equipment provide real-time data on production status, machine performance, and material flows throughout the factory. Our IoT implementation tracks 127 different data points across our jewelry production lines, enabling predictive maintenance that has reduced unplanned downtime by 68%. This comprehensive monitoring also provides unprecedented transparency for clients who can now track their orders through every production stage via customer portals.

How is artificial intelligence revolutionizing production processes?

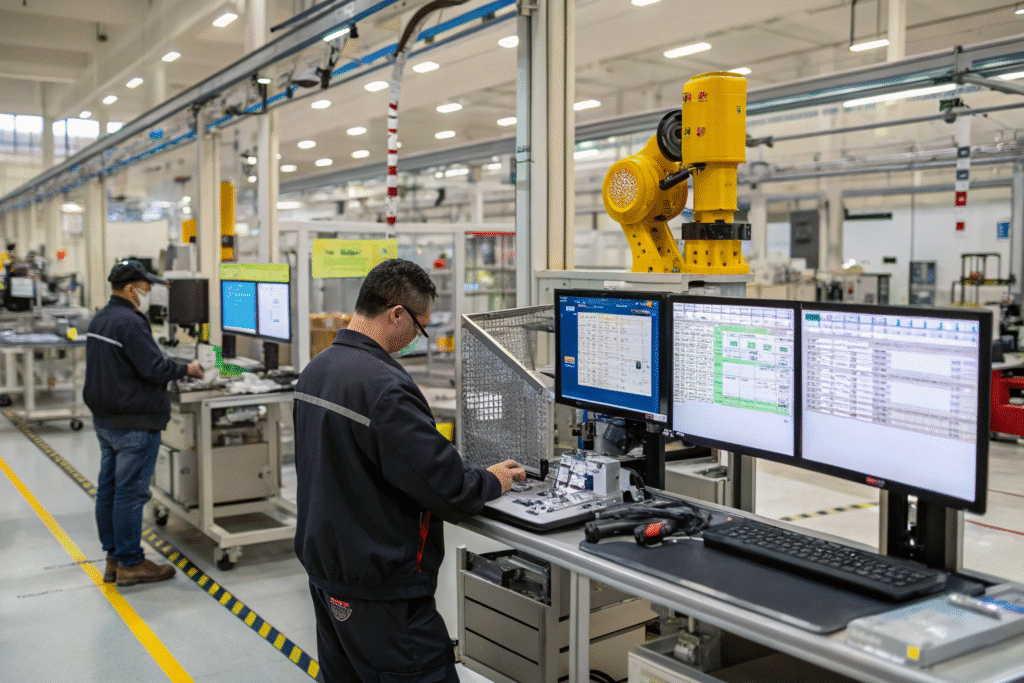

AI technologies are moving beyond experimental applications to become core components of modern accessory manufacturing. From design generation to quality control, machine learning algorithms are introducing new levels of efficiency, precision, and adaptability to factory operations.

The integration of AI is creating factories that not only execute predefined processes but also learn and optimize themselves over time.

How does computer vision enhance quality control in accessory manufacturing?

Automated visual inspection systems trained on thousands of product images can detect defects with superhuman accuracy while operating 24/7 without fatigue. Our AI quality control for metal accessory components identifies surface imperfections, dimensional deviations, and assembly errors with 99.7% accuracy compared to approximately 92% for human inspectors. This precision inspection has reduced customer returns by 57% while freeing quality control staff to focus on more complex evaluation tasks.

What benefits does predictive analytics bring to production planning?

Machine learning algorithms analyze historical data, current orders, and external factors to optimize production schedules, material procurement, and inventory levels. Our predictive planning system has reduced material shortages by 82% while decreasing excess inventory by 44% through more accurate demand forecasting and lead time calculations. This data-driven planning has been particularly valuable for managing the seasonal spikes that characterize fashion accessory demand.

How is additive manufacturing changing accessory production?

3D printing technologies have evolved from prototyping tools to viable production methods for fashion accessories, enabling new design possibilities, mass customization, and supply chain simplification. The technology is particularly transformative for complex geometric designs, personalized items, and low-volume production that would be economically challenging with traditional manufacturing.

Additive manufacturing introduces unprecedented design freedom while reducing material waste and tooling costs.

What role does 3D printing play in custom accessory production?

Direct digital manufacturing enables economical production of unique, personalized items without the tooling costs that traditionally made small batches prohibitive. Our 3D printing capabilities allow customers to design custom jewelry, belt buckles, and hair accessories that we manufacture in quantities as small as one unit while maintaining profitability. This on-demand production model has opened new market segments that were previously inaccessible due to economic constraints of traditional manufacturing.

How does additive manufacturing enhance design innovation?

Generative design algorithms working with 3D printing create intricate structures that are both lightweight and durable, overcoming traditional manufacturing constraints. Our collaboration with designers has produced accessory collections featuring complex lattice structures, interlocking components, and organic forms that would be impossible to manufacture using conventional methods. This design liberation has become a key differentiator in markets where consumers seek unique, statement pieces rather than mass-produced items.

How are sustainable technologies driving digital transformation?

Environmental concerns and consumer demand for eco-friendly products are accelerating the adoption of digital technologies that enable more sustainable manufacturing practices. From material optimization to energy management, digital tools are helping factories reduce their environmental impact while improving economic performance.

Sustainability and digitalization are increasingly intertwined, with digital technologies providing the visibility and control needed to implement genuine environmental improvements.

How does digitalization support circular economy initiatives?

Material tracking systems monitor resource flows throughout production, identifying waste reduction opportunities and enabling recycling or repurposing of production remnants. Our digital material management has identified that 28% of our leather waste could be repurposed into smaller accessories rather than discarded, creating new revenue streams while reducing environmental impact. This waste valorization represents the practical implementation of circular economy principles through digital visibility.

What role do energy management systems play in sustainable digitalization?

Smart energy monitoring optimizes electricity consumption across factory operations, identifying inefficiencies and automating energy-saving measures. Our IoT energy management system has reduced our power consumption by 31% through optimized equipment scheduling, automated lighting controls, and identification of energy-intensive processes that needed efficiency improvements. This resource optimization delivers both environmental benefits and cost savings, demonstrating that sustainability and profitability can be mutually reinforcing.

Conclusion

The digitalization of fashion accessories factories represents a fundamental transformation in how products are conceived, created, and delivered. The trends of end-to-end integration, AI implementation, additive manufacturing adoption, and sustainable technology integration are collectively creating manufacturing environments that are simultaneously more efficient, flexible, and responsible than their traditional counterparts.

As these digital trends continue to evolve and converge, they will increasingly define the competitive landscape of the accessories industry, separating forward-thinking manufacturers from those clinging to outdated methods. The factories that embrace these trends position themselves not just for operational excellence but for leadership in an industry undergoing rapid digital transformation.

If you're looking to digitalize your accessory manufacturing operations or want to partner with a factory at the forefront of these trends, we invite you to contact our Business Director, Elaine. She can discuss our digital capabilities and how they can enhance your accessory production. Reach her at: elaine@fumaoclothing.com.