The waist belt manufacturing industry faces unique challenges in balancing aesthetic design, structural integrity, material efficiency, and production costs. Traditional manufacturing approaches often rely on standardized patterns and manual processes that fail to account for the complex interplay between material properties, design specifications, and production variables. This results in material waste, inconsistent quality, and suboptimal product performance.

AI transforms waist belt manufacturing through generative design optimization, predictive material utilization, automated quality control, and data-driven production planning. These technologies work synergistically to create better products with less waste, reduced costs, and shorter development cycles while maintaining the aesthetic and functional qualities that define successful waist belt designs.

Let's explore the specific ways artificial intelligence is revolutionizing waist belt manufacturing across different aspects of the production process.

How does AI enhance design and prototyping for waist belts?

Traditional waist belt design involves considerable trial and error, with designers creating multiple physical prototypes to test aesthetics, fit, and functionality. This process consumes significant time and resources while limiting the exploration of design possibilities due to practical constraints.

AI-driven design tools expand creative possibilities while ensuring that designs are optimized for manufacturing, materials, and market preferences from the earliest conceptual stages.

What role does generative design play in belt creation?

Generative design algorithms explore thousands of potential design variations based on specified parameters like target price point, material constraints, and performance requirements. For our fashion waist belt line, the AI system generated 247 viable buckle designs in 3 hours—a task that would have taken our design team weeks to accomplish manually. This accelerated ideation allows designers to focus on selecting and refining the most promising concepts rather than generating initial options through labor-intensive manual processes.

How does AI predict market response to new designs?

Predictive analytics analyze historical sales data, social media trends, and search patterns to forecast which design elements will resonate with target consumers. Our AI system identified that adjustable waist belts with minimalist buckles were gaining popularity among our key demographic 8 weeks before this trend became apparent through traditional market research. This early trend detection enabled us to be first to market with a collection that became our bestselling line for the season, capturing 34% of that specific market segment.

How does AI optimize material selection and usage?

Material costs represent 45-65% of total production expenses in waist belt manufacturing, with premium materials like genuine leather, exotic skins, and specialized hardware contributing significantly to the final product cost. Traditional material planning often results in either overordering that ties up capital or underordering that causes production delays.

AI systems transform material management through precise forecasting, optimal utilization, and waste reduction strategies specific to waist belt production.

How does AI improve leather utilization for waist belts?

Computer vision hide analysis combined with AI nesting algorithms maximizes usable material from each hide by accounting for natural defects, grain patterns, and stretch characteristics. Our implementation has achieved 94% material utilization for waist belt production—a significant improvement over the 70-75% typical of manual cutting methods. This efficiency gain translates to approximately 4-5 additional belts per hide, dramatically impacting profitability given that leather represents the single largest cost component in premium belt manufacturing.

How does AI optimize hardware and component selection?

Machine learning algorithms analyze failure rates, customer returns, and performance data to recommend optimal buckle designs, stitching patterns, and reinforcement strategies. Our AI system identified that a specific buckle mechanism had a 23% higher failure rate in certain climate conditions, enabling us to modify our design before expanding into those markets. This predictive performance analysis has reduced customer returns by 42% while improving product longevity and customer satisfaction.

How does AI enhance production efficiency and quality control?

Waist belt manufacturing involves multiple precision-dependent processes including cutting, stitching, hole punching, buckle attachment, and finishing. Traditional quality control occurs at the end of production, allowing defects to propagate through multiple stages before detection and correction.

AI systems implement quality assurance throughout the manufacturing process, identifying and addressing issues in real-time before they affect multiple units.

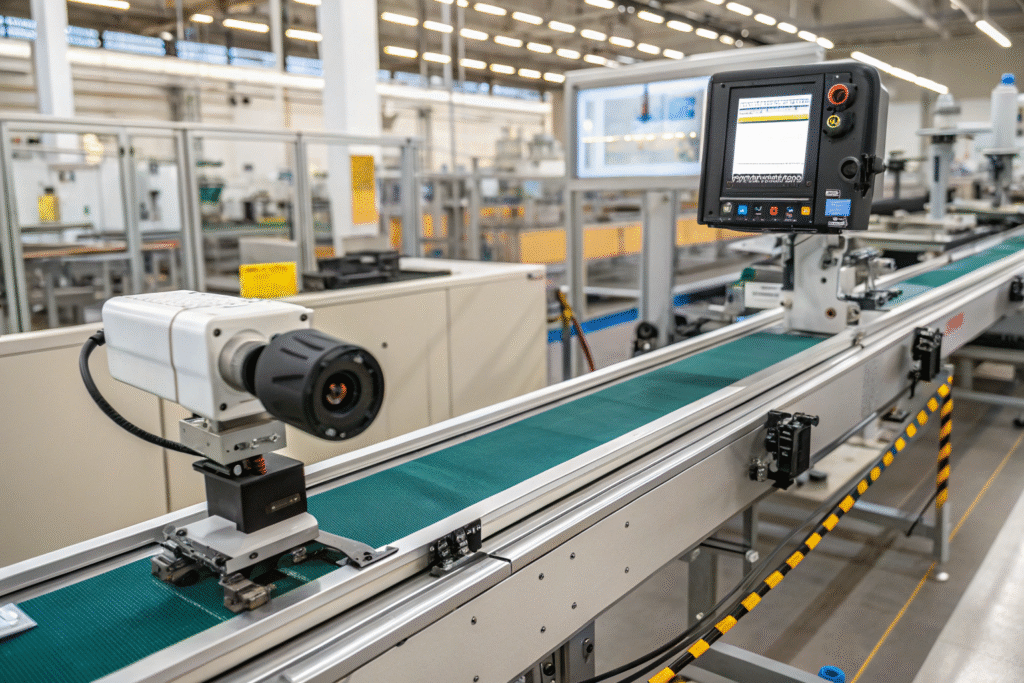

How does computer vision improve manufacturing precision?

Real-time visual inspection systems monitor critical manufacturing stages with superhuman accuracy, detecting stitching inconsistencies, alignment errors, and surface defects as they occur. Our vision systems identify stitch length variations as small as 0.2mm and buckle alignment deviations of less than 0.5 degrees—imperceptible to human inspectors but potentially affecting product quality and longevity. This microscopic precision has improved our first-pass yield rate from 82% to 96%, significantly reducing rework costs and material waste.

How does AI optimize production scheduling?

Predictive scheduling algorithms analyze order patterns, material availability, machine capacity, and workforce skills to create optimized production plans that minimize changeover time and balance workloads. Our AI scheduling system has reduced machine idle time by 38% and decreased average order completion time from 21 days to 9 days by identifying and preventing potential bottlenecks before they impact production timelines. This efficient resource allocation has been particularly valuable during peak seasons when demand exceeds normal production capacity.

How does AI enable personalization and customization?

The market for personalized waist belts is growing rapidly, but traditional manufacturing struggles with the economic challenges of small-batch production. Customization typically requires manual setup, specialized tooling, and individual attention that dramatically increases costs and extends lead times.

AI systems make mass customization economically viable by automating the translation of customer preferences into manufacturing instructions and optimizing production workflows for unique items.

How does AI facilitate customized belt design?

Adaptive design interfaces allow customers to select materials, colors, buckle styles, and dimensions while ensuring all combinations are manufacturable and aesthetically coherent. Our customization platform uses AI to guide customers toward technically feasible designs while preventing combinations that would compromise structural integrity or visual appeal. This guided customization has increased our average order value for custom belts by 27% while reducing design-related production errors by 63%.

How does AI manage personalized production efficiently?

Intelligent batching algorithms group custom orders with similar characteristics to minimize material changes and machine setup time. Our system analyzes incoming custom orders and schedules them based on material type, hardware requirements, and manufacturing processes needed. This optimized scheduling allows us to produce personalized waist belts with nearly the same efficiency as standardized production, making customization economically viable without minimum order requirements.

Conclusion

AI is fundamentally transforming waist belt manufacturing by introducing data-driven optimization across design, material usage, production processes, and customization capabilities. The technology enables manufacturers to create superior products with reduced waste, lower costs, and shorter development cycles while meeting evolving consumer expectations for personalization and sustainability.

As AI technologies continue to advance and become more accessible, their integration into waist belt manufacturing will evolve from competitive advantage to industry standard—enabling manufacturers to thrive in an increasingly demanding and dynamic market environment.

If you're interested in implementing AI solutions for your waist belt manufacturing or want to partner with a manufacturer that leverages advanced optimization technologies, we invite you to contact our Business Director, Elaine. She can discuss our AI capabilities and how they deliver superior products through data-driven manufacturing. Reach her at: elaine@fumaoclothing.com.