The accessories industry has traditionally operated on mass production models, offering limited customization options due to technical and economic constraints. Customers had to choose from predetermined designs, colors, and materials, with personalization typically limited to simple monogramming or minor variations. This one-size-fits-all approach often left consumers compromising on their exact preferences.

Digitalization has revolutionized customization in the accessories industry by enabling direct customer input into design, facilitating small-batch production, streamlining manufacturing processes, and creating seamless omnichannel experiences.This transformation allows customers to become co-creators of their accessories while maintaining efficient production and competitive pricing.

Let's explore the specific digital technologies driving this customization revolution and how they're being implemented across different accessory categories.

How have digital design tools transformed customer participation in creation?

Traditional accessory design was an exclusive process handled by professional designers, with customers only seeing finished products. Digital tools have democratized this process, allowing customers to directly influence and even create their own designs through intuitive platforms.

Advanced software, 3D modeling, and real-time visualization technologies have made professional-level design accessible to consumers while maintaining manufacturing feasibility.

What role do 3D configurators play in accessory customization?

3D product configurators allow customers to visualize their custom creations in real-time, adjusting materials, colors, patterns, and dimensions with immediate visual feedback. For hair accessories, customers can see how different clip designs look with various decorative elements before ordering. Our implementation of virtual customization platforms has increased conversion rates by 34% and reduced return rates by 62%, as customers better understand what they're ordering and feel more connected to their creations.

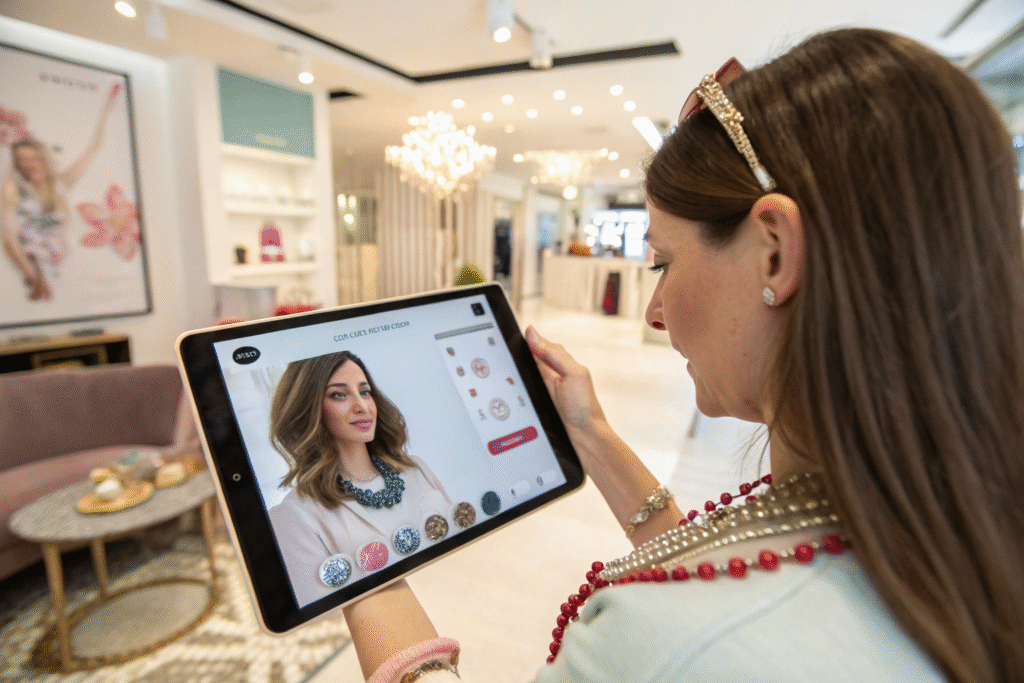

How does augmented reality enhance the customization experience?

Augmented reality applications enable customers to virtually "try on" customized accessories using their smartphone cameras or AR mirrors in physical stores. This technology is particularly valuable for items like statement necklaces, hats, and hair pieces where scale and proportion relative to the wearer's features are crucial. Our AR implementation allows customers to see how different scarf patterns and sizes complement their outfits and body type, creating confidence in customization choices before purchase.

How has digital manufacturing enabled economical small-batch production?

Traditional manufacturing required large minimum order quantities to justify setup costs, making customization economically unviable except for luxury segments. Digital manufacturing technologies have dramatically reduced these barriers, enabling cost-effective production of single items or small batches.

Technologies like 3D printing, digital cutting, and computer-controlled embroidery have transformed the economic model of customized accessory production.

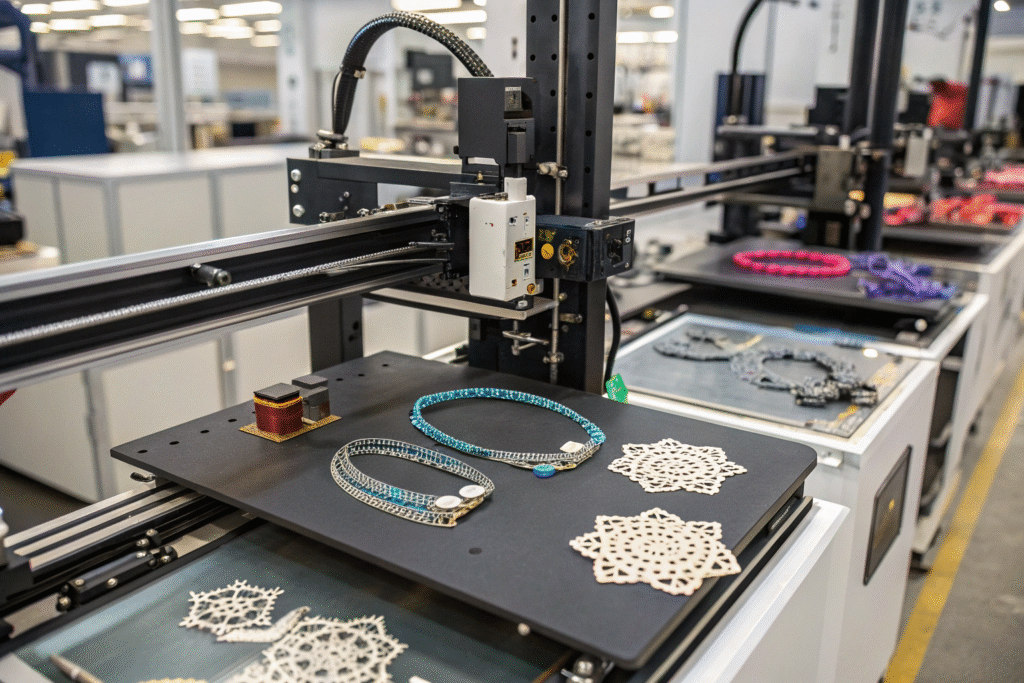

What manufacturing technologies support on-demand customization?

3D printing enables creation of unique accessory components without expensive molds or tooling, making individualized designs economically feasible. Digital textile printing allows for unlimited pattern variations without minimum quantity requirements. Our factory utilizes laser cutting systems that can cut custom shapes from various materials based on digital files submitted by customers. This technological infrastructure allows us to produce customized belts with unique buckle designs and personalized patterns in batches as small as one unit while maintaining profitability.

How does digital workflow integration streamline custom orders?

Digital production management systems automatically translate customer designs into manufacturing instructions, scheduling them efficiently alongside standard production. When a customer creates a custom hair accessory through our online platform, the system automatically generates production files, calculates material requirements, and schedules the job on appropriate equipment. This seamless digital integration has reduced our custom order lead time from 3 weeks to just 5 days while improving accuracy and reducing manual processing errors by 78%.

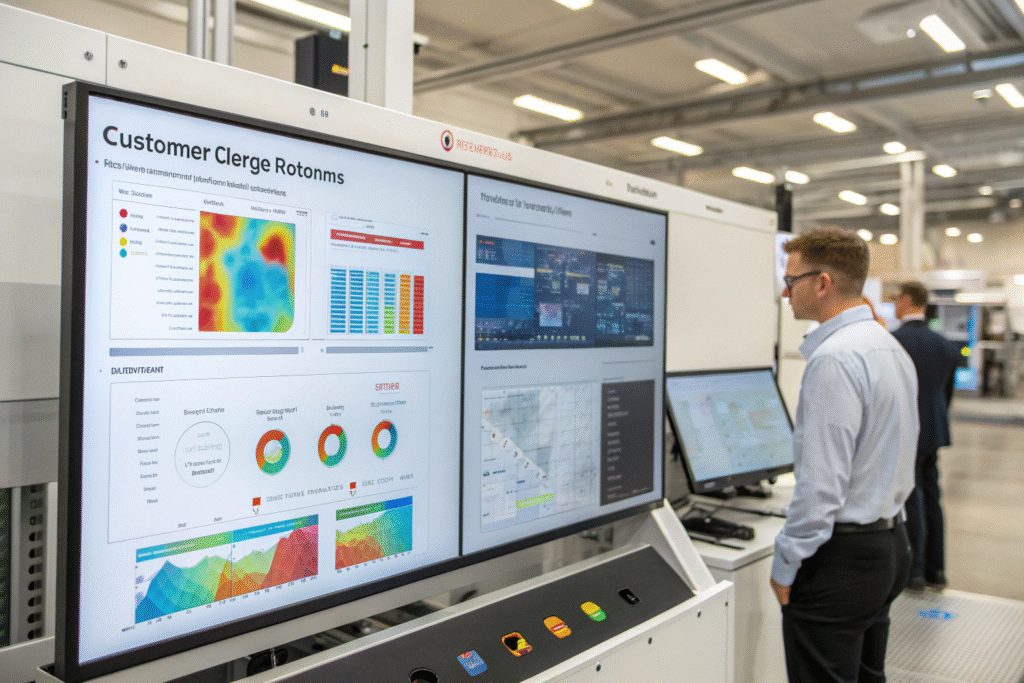

How have data analytics and AI enhanced personalization?

Digitalization generates vast amounts of data about customer preferences, behaviors, and customization patterns. Advanced analytics and artificial intelligence transform this data into actionable insights that enhance both the customization experience and the relevance of suggested options.

Machine learning algorithms identify patterns and preferences that help guide customers toward personalized choices they're likely to appreciate.

How do recommendation engines improve customization outcomes?

AI-powered recommendation systems analyze customer preferences, past purchases, and similar users' choices to suggest customization options that align with individual tastes. For scarf customization, our system recommends color palettes and pattern styles based on a customer's previous selections and stated preferences. This intelligent guidance has increased customer satisfaction with custom orders by 41% and reduced abandoned customization sessions by 57%, as customers feel supported rather than overwhelmed by choices.

What role does predictive analytics play in customization?

Predictive analytics identify emerging customization trends by analyzing data from thousands of design interactions. This allows manufacturers to pre-emptively develop materials, components, and design options that align with evolving customer preferences. Our analysis of customization data revealed an emerging preference for modular hair accessories that can be reconfigured, leading us to develop a successful new product category that saw 28% customization rates in its first quarter.

How has digital integration improved the end-to-end customization journey?

The customization experience extends beyond the initial design phase to include ordering, production tracking, and post-purchase engagement. Digital platforms create seamless omnichannel experiences that keep customers engaged throughout their customization journey.

Integrated systems provide transparency, communication, and ongoing relationship building that enhances the value of customized purchases.

How do digital platforms enhance the customization communication loop?

Integrated customer portals allow clients to track their custom orders through every production stage, from material sourcing to manufacturing to shipping. For our business clients ordering customized promotional accessories, the portal provides real-time updates and the ability to make minor adjustments until production begins. This transparent communication has increased client satisfaction scores by 36% and strengthened long-term relationships, as customers feel involved and informed throughout the creation process.

What role does IoT play in streamlining custom manufacturing?

IoT sensors in our manufacturing equipment provide real-time data on production status, material usage, and quality metrics for each custom order. This connectivity allows for automatic adjustments and proactive issue resolution. For example, if a sensor detects that material tension is varying during production of a custom woven belt, the system automatically adjusts parameters to maintain consistency with the customer's design specifications. This smart manufacturing approach has improved quality consistency for custom orders by 29% compared to manual processes.

Conclusion

Digitalization has fundamentally transformed customization in the accessories industry, moving it from a niche luxury service to an accessible, engaging experience available to mainstream consumers. By leveraging digital design tools, advanced manufacturing technologies, data analytics, and integrated platforms, manufacturers can offer unprecedented personalization while maintaining efficiency and profitability.

As these technologies continue to evolve and become more sophisticated, we can expect customization to become increasingly seamless, intelligent, and integrated into the standard accessory shopping experience, ultimately blurring the lines between consumer and creator.

If you're interested in exploring digital customization options for your accessory line or want to partner with a manufacturer that specializes in personalized production, we invite you to contact our Business Director, Elaine. She can discuss our digital capabilities and how they can be tailored to your specific customization needs. Reach her at: elaine@fumaoclothing.com.