The fashion accessory industry faces growing challenges around sustainability, customization, and material innovation. Traditional manufacturing methods often generate significant waste and have limited ability to create complex, personalized designs. Consumers increasingly demand eco-friendly products and unique items that reflect their individual style.

Bioprinting promises to revolutionize fashion accessory manufacturing by enabling sustainable material production, unprecedented customization, and complex biological designs impossible with conventional methods.This emerging technology uses living cells, bio-inks, and 3D printing techniques to create organic and hybrid materials that could transform how accessories are designed, produced, and experienced.

Let's explore how this cutting-edge technology might reshape the future of fashion accessories from materials to manufacturing processes.

How will bioprinting transform accessory materials?

Current accessory materials often rely on petroleum-based plastics, mined metals, and animal-derived products that raise environmental and ethical concerns. The production processes typically generate substantial waste and have limited options for material properties customization.

Bioprinting enables creation of biodegradable, lab-grown materials with tailored characteristics - from flexibility and durability to color and texture - while dramatically reducing environmental impact.

What types of bioprinted materials will replace conventional options?

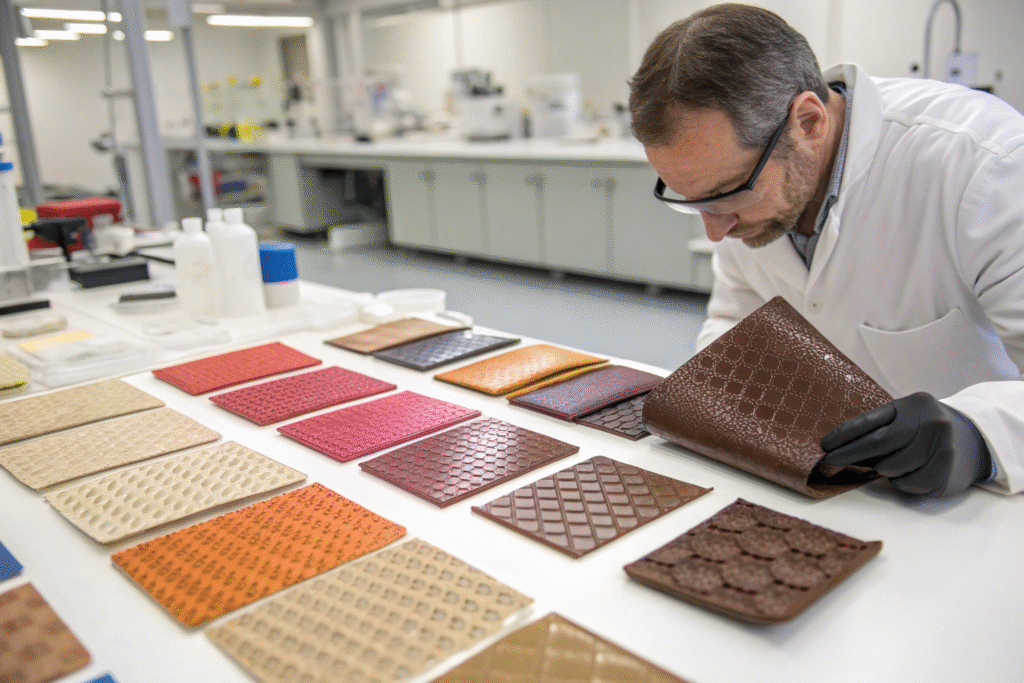

Bioprinting technology can produce mushroom-based leather alternatives for handbags and belts, algae-derived polymers for hair accessories, and cellulose-based materials for decorative elements. These sustainable materials offer similar durability and aesthetic qualities to traditional options while being completely biodegradable. For example, our research department is experimenting with marine-derived bio-inks that could replace plastic components in hair clips and decorative elements, creating products that return harmlessly to the environment at end of life.

How can material properties be customized through bioprinting?

Unlike conventional materials with fixed properties, bioprinted substances can be engineered at the molecular level. By adjusting bio-ink compositions and printing parameters, manufacturers can create materials with specific flexibility, strength, transparency, or color characteristics. This means a single production process could create rigid bracelet frames and flexible connecting elements using the same base material, simply by varying the printing approach. This customization potential could revolutionize how designers approach accessory creation.

How will customization capabilities evolve with bioprinting?

Mass production has dominated accessory manufacturing because custom creation has been prohibitively expensive and time-consuming. This one-size-fits-all approach limits consumer choice and creates inventory waste when designs don't resonate with the market.

Bioprinting enables true mass customization where unique designs can be produced as efficiently as standardized items, opening new possibilities for personal expression and perfect fit.

What level of personalization will bioprinting enable?

Future consumers might use body scanning apps to create perfectly fitted headbands or earrings that match their exact anatomy and style preferences. Bioprinting could produce accessories incorporating a customer's chosen patterns, embedded meaningful symbols, or even biologically-compatible pieces that integrate with wearable technology. This shift from mass production to mass customization represents one of the most significant transformations bioprinting could bring to the fashion industry.

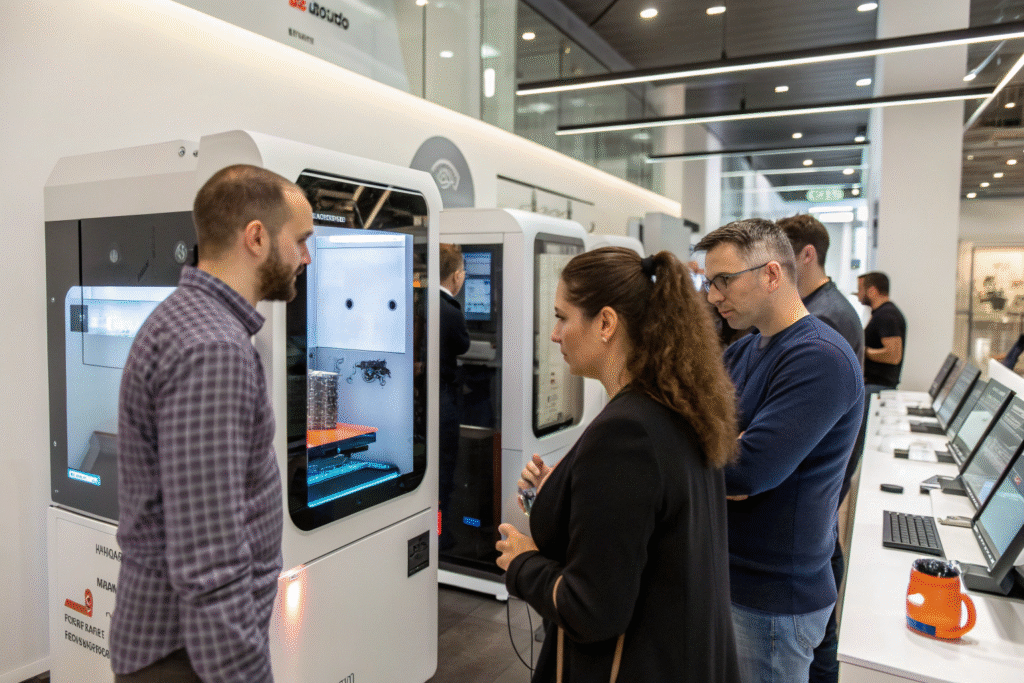

How might bioprinting change design and prototyping processes?

Designers will be able to create and test intricate biological structures that are impossible to manufacture traditionally. Complex lattice designs for lightweight yet strong statement necklaces, gradient color transitions, and integrated living elements become feasible with bioprinting. The prototyping cycle could shrink from weeks to hours, allowing designers to experiment more freely and respond instantly to emerging trends. This accelerated creativity could lead to entirely new accessory categories and forms.

What sustainability benefits will bioprinting provide?

The fashion industry is under increasing pressure to reduce its environmental footprint, with accessory manufacturing contributing to plastic pollution, water contamination, and resource depletion. Current sustainability efforts often focus on mitigating harm rather than fundamentally redesigning production systems.

Bioprinting offers a paradigm shift toward circular manufacturing where accessories are grown rather than assembled, using renewable resources and designed for complete biodegradability or reuse.

How will bioprinting reduce fashion's environmental impact?

Bioprinted accessories will utilize renewable biological resources instead of petroleum-based plastics and mined metals. The production process typically requires less water and energy than conventional manufacturing and generates minimal waste since materials are deposited precisely where needed. End-of-life scenarios become more sustainable too - accessories could be designed to biodegrade safely or be returned to manufacturers for "re-bioforming" into new products. This circular approach could significantly reduce the environmental impact of accessory production.

Can bioprinting eliminate toxic chemicals from accessory production?

Traditional accessory manufacturing often involves dyes, finishes, and processing chemicals that can harm ecosystems and workers. Bioprinting can incorporate color and desired properties directly into the bio-inks, eliminating many toxic processing steps. Living color systems using structural color or natural pigments could replace synthetic dyes. Our sustainability team is exploring how bacterial cellulose infused with natural chromatic properties could create vibrant scarves and hair accessories without traditional dyeing processes.

What challenges must be overcome for widespread adoption?

Despite its promise, bioprinting faces significant technical, economic, and regulatory hurdles before becoming mainstream in fashion accessory manufacturing. The technology is currently in early stages, with most applications confined to research laboratories and small-scale demonstrations.

Overcoming these challenges requires coordinated efforts across scientific research, engineering development, business model innovation, and consumer education.

What are the current technical limitations of bioprinting for accessories?

Current bioprinting technology struggles with production speed, material durability, and cost-effectiveness compared to conventional manufacturing. Creating accessories that meet consumer expectations for longevity, water resistance, and mechanical strength remains challenging. Scaling from laboratory samples to commercial production volumes requires significant engineering advances in bioprinter design, bio-ink production, and post-processing techniques. These technical barriers are substantial but not insurmountable with continued research investment.

How will regulatory frameworks adapt to bioprinted fashion items?

Bioprinted products occupy a unique space between fashion, biotechnology, and consumer goods that existing regulations weren't designed to address. Questions about safety standards, labeling requirements, and intellectual property will need resolution before widespread market adoption. Regulatory agencies are beginning to consider how to classify and oversee these novel products, but clear frameworks will take time to develop. Manufacturers exploring this space must engage early with regulatory considerations to ensure compliant market entry.

Conclusion

Bioprinting represents a transformative frontier in fashion accessory manufacturing, offering solutions to some of the industry's most pressing challenges around sustainability, customization, and material innovation. While the technology is still emerging, its potential to create environmentally responsible, highly personalized, and biologically-inspired accessories could fundamentally reshape the industry within the next decade.

The companies that begin exploring bioprinting applications today will be best positioned to lead this exciting transition toward a more sustainable and creative future for fashion accessories.

If you're interested in staying ahead of manufacturing innovations and exploring future production technologies for your accessory lines, we invite you to contact our Business Director, Elaine. She can discuss our research initiatives and how we're preparing for the next generation of accessory manufacturing. Reach her at: elaine@fumaoclothing.com.