Producing bracelets with perfect quality is challenging. Small defects like missing crystals, imperfect clasps, or color variations can lead to customer returns and damage your brand reputation. Traditional manual inspection often misses these tiny flaws, especially during high-volume production runs.

Automated Optical Inspection (AOI) provides significant advantages for bracelet manufacturing, including near-perfect defect detection, consistent quality control, massive cost savings, and detailed production analytics. This technology uses high-resolution cameras and sophisticated algorithms to identify imperfections human eyes might miss, ensuring every bracelet meets your quality standards before shipment.

Let me explain why AOI has become essential for modern jewelry manufacturing and how it can transform your bracelet quality control process.

How does AOI improve defect detection in bracelet production?

Manual inspection relies on human eyesight and attention span, both of which decline over long shifts. Workers can miss small defects after hours of repetitive checking, especially with intricate bracelet designs featuring multiple components.

Automated Optical Inspection systems maintain consistent performance 24/7, detecting even microscopic flaws that human inspectors might overlook. This technology excels at identifying common bracelet defects like missing gemstones, cracked beads, clasp malfunctions, and surface scratches with incredible accuracy.

What types of bracelet defects can AOI identify?

Automated Optical Inspection systems can detect numerous defect types specific to bracelet manufacturing. For metallic bracelets, AOI identifies surface scratches, plating inconsistencies, and link deformations. For beaded bracelets, it spots color variations, size discrepancies, and cracked beads. With crystal bracelets, the system detects missing stones, misaligned settings, and adhesive residue. This comprehensive inspection capability ensures that only perfect products reach your customers, significantly reducing returns and complaints.

How does AOI achieve higher accuracy than manual inspection?

AOI systems use multiple high-resolution cameras with specialized lighting to capture detailed images from various angles. Advanced algorithms then analyze these images against predefined quality parameters. Unlike human inspectors who fatigue over time, optical inspection systems maintain consistent accuracy throughout production runs. They can inspect thousands of bracelets per hour while detecting flaws as small as 0.1mm – dimensions virtually invisible to the naked eye during rapid manual inspection.

How does automated inspection reduce manufacturing costs?

While AOI systems require initial investment, they deliver substantial cost savings by preventing defective products from progressing through the production chain. Early defect detection means less rework, reduced material waste, and lower return rates.

The financial benefits extend beyond simple defect prevention to include labor optimization, faster production cycles, and improved customer satisfaction that drives repeat business.

What is the ROI timeline for implementing AOI systems?

Most manufacturers recover their AOI system investment within 12-18 months through quantifiable savings. The reduction in customer returns alone often justifies the equipment cost, especially for medium to high-volume production. Additional savings come from reduced manual inspection labor, lower scrap rates, and decreased rework requirements. For bracelet manufacturers producing over 10,000 units monthly, the financial benefits become apparent within the first production year.

How does early defect detection minimize waste?

AOI systems typically identify defects immediately after assembly, preventing flawed bracelets from undergoing subsequent value-adding processes like polishing, plating, or packaging. This early detection significantly reduces material waste and processing costs on defective units. For example, identifying a clasp defect before polishing saves both the polishing cost and the time that would be wasted on an unsalable product. This proactive approach optimizes your entire manufacturing workflow.

How does AOI enhance production efficiency and speed?

Manual inspection creates natural bottlenecks in production lines. Human inspectors can only check a limited number of bracelets per hour while maintaining accuracy, forcing manufacturers to either slow production or risk quality compromises.

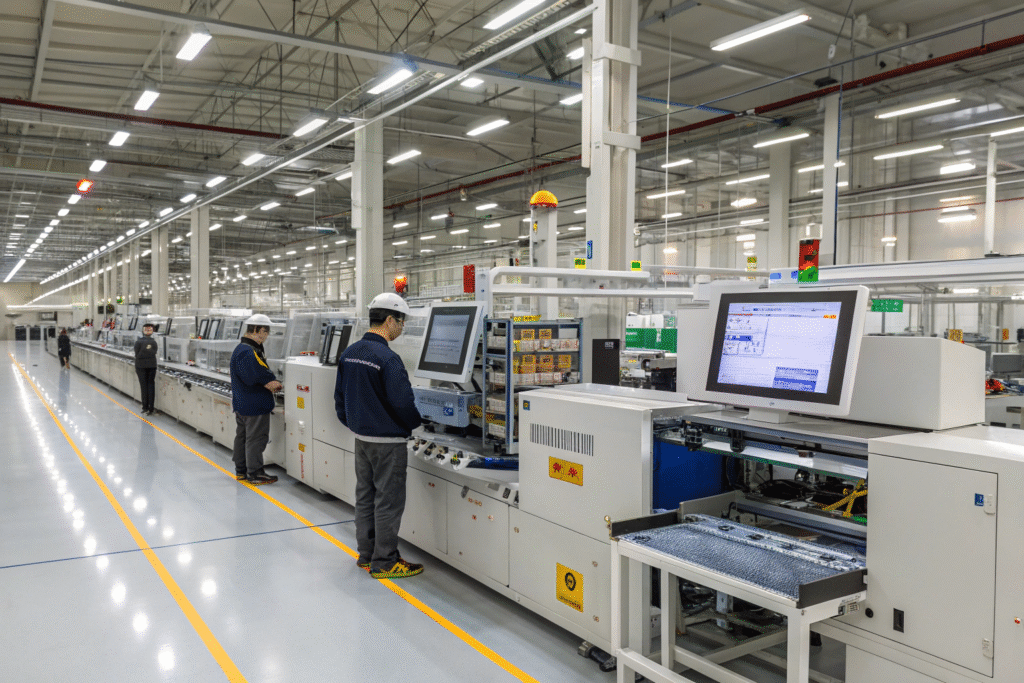

Automated inspection systems maintain both high speed and accuracy, seamlessly integrating with existing production lines to maintain optimal workflow without sacrificing quality standards.

What inspection speeds can AOI systems achieve?

Modern AOI equipment can inspect thousands of bracelets per hour, far surpassing manual capabilities. The inspection speed depends on bracelet complexity and the number of quality parameters being checked. Simple chain bracelets might be inspected at rates exceeding 3,000 units per hour, while intricate designs with multiple components might process at 1,000-1,500 units hourly. This speed maintains production flow while ensuring comprehensive quality control.

How does AOI integrate with existing production lines?

AOI systems are designed for seamless integration into existing manufacturing workflows. They can be positioned at critical control points – after assembly, before plating, or during final packaging. Modern systems feature standardized interfaces that connect with production monitoring software, providing real-time quality data to operators. This integration creates a continuous feedback loop where detection trends can trigger immediate process adjustments, preventing defect recurrence.

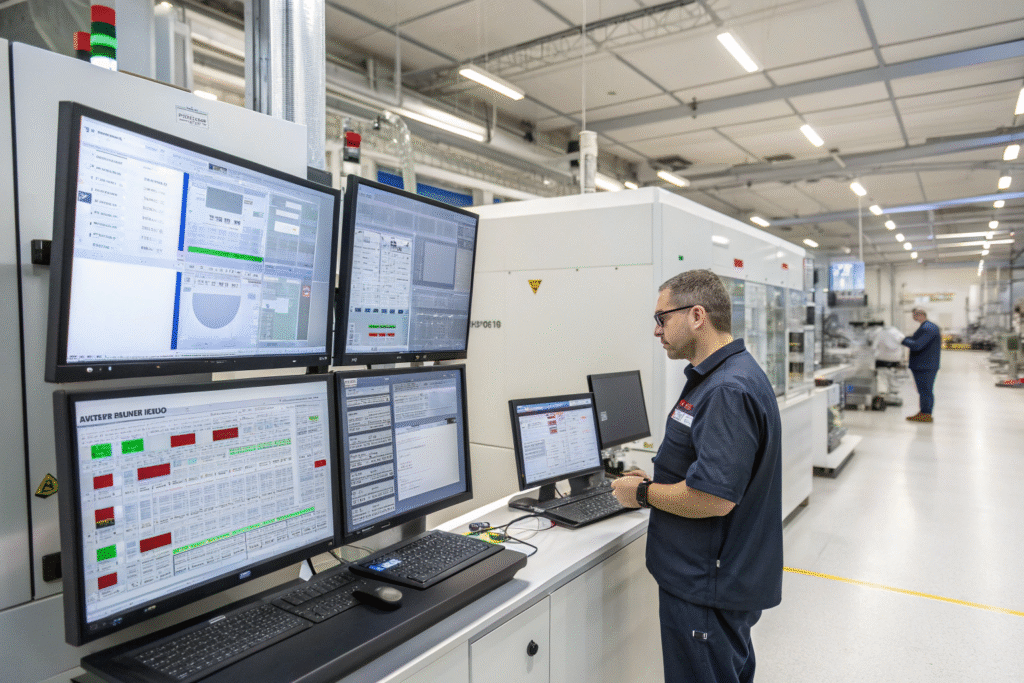

How does AOI provide valuable production analytics?

Beyond simple defect detection, AOI systems generate comprehensive data that provides insights into your manufacturing process. This data-driven approach transforms quality control from a reactive to a proactive function.

The analytics capabilities help identify patterns, predict maintenance needs, and optimize production parameters for continuous improvement.

What types of production data does AOI generate?

AOI systems collect extensive data including defect type frequencies, location patterns, time-based occurrence trends, and correlation with specific production batches. This information creates a detailed quality profile of your manufacturing process. For bracelet production, you might discover that clasp defects increase during certain shifts or that crystal misalignment correlates with specific assembly stations. These insights enable targeted process improvements rather than generalized corrections.

How can manufacturers use AOI data for process improvement?

The statistical data from AOI systems enables true continuous improvement in manufacturing. By analyzing defect trends, manufacturers can identify root causes and implement preventive measures. For example, if data shows increasing scratches on metallic bracelets, you might investigate and adjust handling procedures or equipment maintenance schedules. This data-driven approach systematically reduces defect rates over time, leading to higher overall quality and customer satisfaction.

Conclusion

Automated Optical Inspection delivers transformative advantages for bracelet manufacturing, providing near-perfect quality control, significant cost reduction, enhanced production efficiency, and valuable process analytics. While the initial investment requires consideration, the long-term benefits of reduced returns, improved customer satisfaction, and streamlined operations make AOI an essential technology for competitive jewelry manufacturers.

The data-driven approach enabled by AOI transforms quality management from reactive problem-solving to proactive prevention, creating a foundation for continuous improvement and manufacturing excellence.

If you're looking to implement comprehensive quality control for your bracelet production, we invite you to contact our Business Director, Elaine. She can discuss how our manufacturing facilities incorporate AOI technology to ensure exceptional product quality. Reach her at: elaine@fumaoclothing.com.