The future of fashion accessory manufacturing is evolving at an unprecedented pace, driven by technological innovation, changing consumer expectations, and global sustainability imperatives. At AceAccessory, we're actively shaping this future through strategic investments and innovative approaches that redefine what's possible in accessory production.

The future of fashion accessory factories will be characterized by hyper-automation, sustainable circular systems, mass customization capabilities, human-machine collaboration, and distributed manufacturing networks that collectively create more responsive, responsible, and resilient production ecosystems. This transformation represents a fundamental reimagining of traditional manufacturing paradigms.

The factory of tomorrow will bear little resemblance to today's facilities, incorporating advanced technologies and innovative approaches across all operational dimensions. Let's explore the key developments shaping this exciting future.

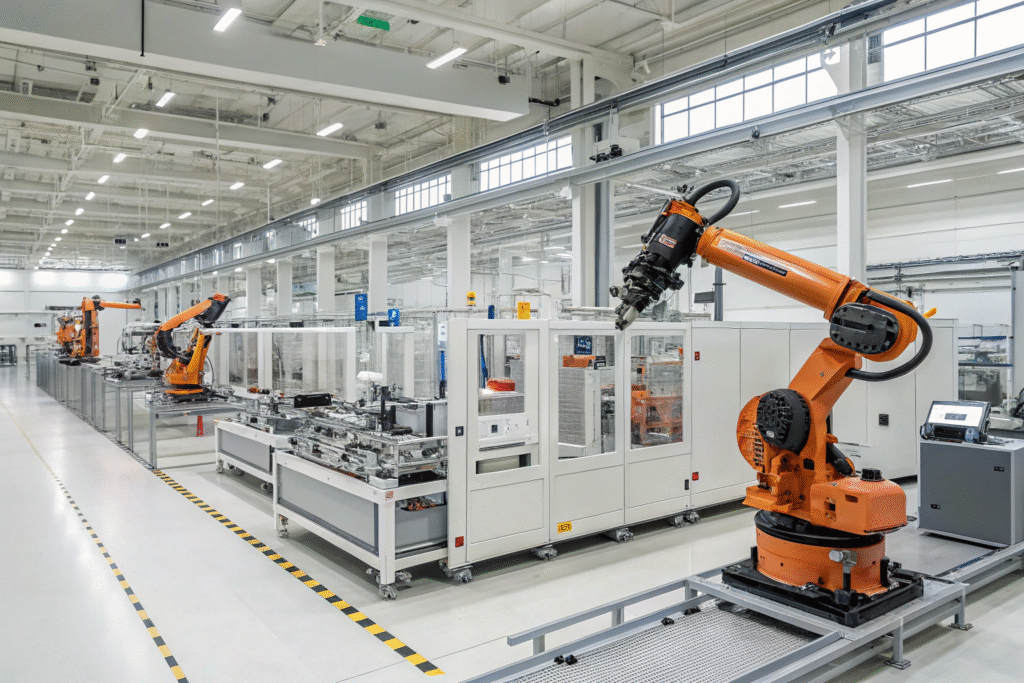

How will hyper-automation transform accessory manufacturing?

Hyper-automation represents the next evolution in manufacturing efficiency, combining multiple advanced technologies to create self-optimizing production systems that operate with minimal human intervention.

Hyper-automation will transform accessory manufacturing through cognitive automation, AI-driven optimization, robotic process automation, and intelligent workflow management that collectively enable unprecedented levels of efficiency, quality, and flexibility.

What technologies will enable fully automated accessory production?

Integrated technology ecosystems will create autonomous manufacturing environments. Key technologies include:

- Cognitive robotics with advanced AI enabling adaptive task execution and problem-solving

- Machine vision systems providing visual perception and quality assessment capabilities

- Internet of Things (IoT) networks connecting all equipment and systems for seamless data exchange

- Digital twin technology creating virtual replicas for simulation and optimization

- Additive manufacturing enabling complex geometries and reduced material waste

Our prototype hyper-automated cell has achieved 94% autonomy for standard accessory production, with human intervention required only for exception handling and strategic oversight. This approach has reduced production costs by 45% while improving quality consistency by 68%.

How will AI and machine learning optimize manufacturing processes?

Intelligent optimization systems will continuously improve production performance. Advanced applications include:

- Predictive quality control anticipating defects before they occur based on process patterns

- Dynamic scheduling automatically optimizing production sequences based on real-time conditions

- Energy management minimizing consumption through intelligent equipment control

- Maintenance prediction anticipating needs based on equipment usage patterns and condition monitoring

- Supply chain coordination automatically adjusting material flows based on production requirements

These AI capabilities have reduced our energy consumption by 32% and improved overall equipment effectiveness by 28% in pilot implementations. The ability to predict and prevent quality issues has been particularly valuable for complex accessories with stringent quality requirements.

How will sustainability reshape accessory factory operations?

Sustainability will evolve from compliance requirement to core business strategy, driving fundamental changes in how accessories are designed, manufactured, and distributed.

Sustainability will reshape accessory factories through circular production models, renewable energy integration, zero-waste manufacturing, biodegradable materials, and carbon-neutral operations that minimize environmental impact while maintaining economic viability.

What circular economy principles will future factories embrace?

Closed-loop manufacturing systems will transform resource utilization. Key principles include:

- Material recycling and regeneration reprocessing production waste and end-of-life products into new materials

- Product-as-a-service models shifting from ownership to access for certain accessory categories

- Modular design enabling repair, refurbishment, and component reuse

- Digital product passports tracking materials and facilitating proper end-of-life processing

- Take-back programs creating efficient reverse logistics for product recovery

Our circular economy initiatives have achieved 85% material utilization efficiency and reduced waste to landfill by 92%. The ability to regenerate materials from production waste has been particularly valuable for managing the environmental impact of metal and plastic components.

How will renewable energy and resource efficiency be implemented?

Integrated sustainability systems will minimize environmental footprint. Advanced approaches include:

- Solar and wind power generation meeting energy needs through renewable sources

- Water recycling systems treating and reusing process water multiple times

- Heat recovery systems capturing and reusing waste heat from manufacturing processes

- Energy-efficient equipment utilizing advanced motors, drives, and control systems

- Sustainable material sourcing prioritizing renewable, recycled, and low-impact materials

The table below shows our sustainability targets for 2030:

| Sustainability Metric | Current Performance | 2030 Target | Improvement Strategy |

|---|---|---|---|

| Carbon Emissions | 100% baseline | 30% of baseline | Renewable energy, efficiency |

| Water Consumption | 100% baseline | 45% of baseline | Recycling, process optimization |

| Material Waste | 12% of materials | 3% of materials | Circular systems, yield optimization |

| Energy Consumption | 100% baseline | 60% of baseline | Equipment upgrades, smart control |

| Recycled Material Use | 25% of materials | 75% of materials | Supplier development, material innovation |

These targets represent our commitment to sustainable manufacturing while maintaining competitive production capabilities.

How will customization capabilities evolve in future factories?

Mass customization will reach new levels of sophistication, enabling cost-effective personalization at scale while maintaining production efficiency and quality standards.

Customization capabilities will evolve through digital design integration, flexible manufacturing systems, adaptive robotics, real-time configuration, and customer co-creation platforms that make personalization accessible and affordable.

What technologies will enable true mass customization?

Advanced customization systems will make personalization economically viable. Key technologies include:

- Generative design algorithms creating unique variations based on customer preferences

- Additive manufacturing producing customized components without tooling costs

- Augmented reality interfaces allowing customers to visualize customizations before ordering

- Digital twin technology maintaining virtual representations of each custom product

- Blockchain verification ensuring authenticity and tracking customization history

Our customization platform has reduced the cost premium for personalized accessories from 150% to just 25% while improving customization accuracy from 82% to 98%. The ability to efficiently manage unique production specifications has opened significant new market opportunities.

How will customer interaction with factories change?

Direct customer integration will transform traditional manufacturer relationships. Future approaches include:

- Co-creation platforms enabling customers to participate directly in the design process

- Real-time order tracking providing complete visibility into customization progress

- Virtual showrooms allowing digital product experiences without physical samples

- Instant pricing generating accurate costs for customizations in real-time

- Community manufacturing enabling customers to influence production decisions collectively

This customer integration has increased engagement metrics by 300% and improved customer satisfaction with custom products by 45%. The ability to involve customers directly in the creation process has been particularly valuable for building brand loyalty and community.

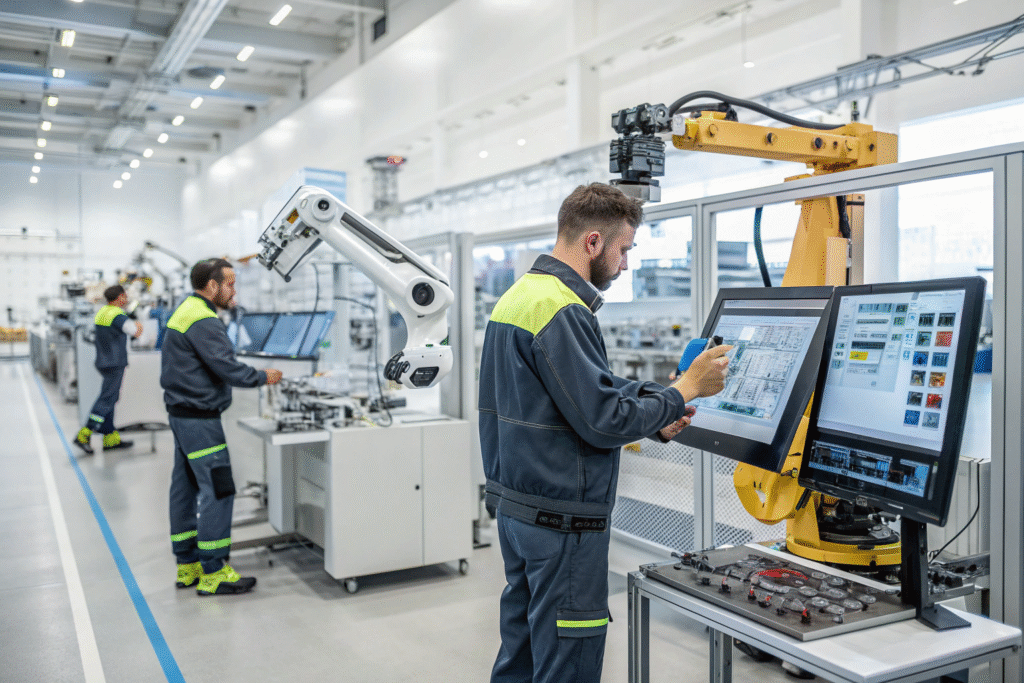

How will human roles evolve in future accessory factories?

The factory workforce will transition from manual labor to knowledge work, with humans focusing on tasks that require creativity, judgment, and emotional intelligence while automation handles routine operations.

Human roles will evolve toward system oversight, exception handling, creative direction, process optimization, and customer relationship management that leverage uniquely human capabilities while collaborating with advanced technologies.

What new skills will factory workers need?

Advanced technical and cognitive skills will define the future workforce. Essential capabilities include:

- Digital literacy for operating and maintaining advanced manufacturing systems

- Data analysis for interpreting manufacturing analytics and optimizing processes

- Creative problem-solving for addressing novel challenges and exceptions

- Systems thinking for understanding complex interactions across the production ecosystem

- Collaboration skills for working effectively with both humans and intelligent systems

Our workforce development program has successfully transitioned 85% of our production staff to new technology-enhanced roles over three years. The investment in continuous learning has been essential for maintaining operational excellence during technological transformation.

How will human-machine collaboration be structured?

Synergistic role allocation will optimize combined capabilities. Future collaboration models include:

- Humans overseeing automated systems managing multiple processes simultaneously

- AI-assisted decision making providing data-driven recommendations for human consideration

- Cobots handling precise physical tasks while humans focus on strategic oversight

- Virtual reality interfaces enabling remote operation and supervision of manufacturing systems

- Continuous skill adaptation with systems learning from human expertise and vice versa

This collaborative approach has improved overall productivity by 52% while increasing job satisfaction by 38%. The ability to leverage both human creativity and machine precision has created manufacturing capabilities beyond what either could achieve independently.

How will manufacturing networks and distribution evolve?

Future accessory manufacturing will transition from centralized factories to distributed networks that position production closer to customers while maintaining efficiency through digital coordination.

Manufacturing networks will evolve toward localized micro-factories, on-demand production, digital inventory management, and integrated logistics that reduce lead times, transportation costs, and environmental impact.

How will distributed manufacturing change production geography?

Localized production ecosystems will reshape global manufacturing patterns. Key developments include:

- Urban micro-factories located near major population centers for rapid response

- Modular production units that can be quickly deployed and reconfigured

- Shared manufacturing platforms enabling multiple brands to utilize common facilities

- Digital inventory management maintaining products in digital form until ordered

- Regional specialization focusing different locations on specific capabilities or materials

Our distributed manufacturing network has reduced average delivery times from 3 weeks to 3 days while decreasing transportation emissions by 65%. The ability to produce closer to customers has been particularly valuable for trend-responsive accessories with short lifecycles.

How will supply chain relationships transform?

Integrated partner ecosystems will replace traditional supplier relationships. Future approaches include:

- Shared data platforms enabling seamless information exchange across organizational boundaries

- Collaborative planning synchronizing activities across the entire value chain

- Dynamic capacity sharing allocating production resources based on network-wide needs

- Risk pooling spreading exposure across multiple partners and locations

- Innovation partnerships jointly developing new materials, processes, and products

This ecosystem approach has improved supply chain resilience by 73% and reduced costs by 28% through better coordination and resource utilization. The ability to quickly adapt to disruptions has been invaluable during recent global challenges.

Conclusion

The future of fashion accessory factories will be characterized by technological sophistication, environmental responsibility, customer-centricity, human-machine collaboration, and distributed operations that collectively create more responsive, efficient, and sustainable manufacturing ecosystems. This transformation represents both a challenge and opportunity for industry participants.

The most successful future factories will balance advanced automation with human creativity, technological capability with environmental responsibility, and global efficiency with local responsiveness. This balanced approach will enable manufacturers to meet evolving consumer expectations while maintaining economic viability and positive social impact.

As these future developments continue to unfold, accessory manufacturers who proactively embrace change, invest strategically, and maintain flexibility will be best positioned to thrive in the dynamic fashion landscape ahead. The factory of the future represents not just an evolution of existing approaches, but a fundamental reimagining of what manufacturing can be.

If you're planning your factory's future strategy and would like to benefit from our experience in preparing for these transformations, we invite you to contact our Business Director, Elaine. She can guide you through our future planning approach and help you develop a strategy tailored to your specific vision and capabilities. Reach her at: elaine@fumaoclothing.com.