When you have a powerful, graphic logo, you want it to pop. You want the color to be rich and vibrant, the lines to be crisp, and the final print to be tough enough to last. While modern methods like digital printing have their place, why do we as manufacturers consistently turn to the age-old technique of silk screen printing for the boldest results?

Why is silk screen printing the best method for bold logos? The answer lies in its unique ability to lay down a thick, opaque, and incredibly vibrant layer of ink in a single pass, creating a level of color saturation and durability that other methods struggle to match, especially on dark-colored accessories. As the owner of Shanghai Fumao Clothing, I can tell you that when it comes to pure, punchy color, screen printing is king.

Is it just an old-fashioned technique, or is there a specific science behind its superiority for bold designs? Let's explore the four key reasons why this method delivers such powerful results.

How Does Ink Opacity Create Such Vibrant Color?

Have you ever tried to draw with a yellow marker on a black piece of paper? The color looks weak and transparent. This is the core challenge of printing on colored or dark fabrics. The color of the fabric shows through the ink, dulling the color of the logo. So, how does screen printing solve this?

The magic is in the opacity and thickness of the ink. Screen printing doesn't use thin, watery dyes; it uses thick, paste-like inks called plastisol or water-based inks. The process involves pushing this thick ink directly through a screen onto the fabric's surface. This lays down a substantial, opaque layer of color that physically sits on top of the fabric, rather than soaking into it. This opaque layer acts as a powerful barrier, completely blocking out the color of the fabric underneath.

What is an "Underbase" and Why is it Crucial for Dark Fabrics?

How do you get a bright red logo on a black hat to look so bright? For dark garments, we use a two-step process. First, we print a layer of white ink (called an underbase) in the shape of the logo. We flash-cure this layer to make it solid. Then, we print the final color (e.g., red) directly on top of this white foundation. The underbase acts as a perfect, bright white primer, ensuring the final color is as bright and true as it would be on a white t-shirt. This technique is fundamental to achieving bold colors on dark accessories.

How Does This Compare to Digital Printing (DTG)?

Doesn't digital printing also use an underbase? Yes, but the process is different. Direct-to-Garment (DTG) printing is essentially an inkjet printer for fabric. It sprays very fine droplets of thinner ink that soak more into the fabric. While it's fantastic for photorealistic images with many colors, the ink layer is much thinner. It cannot achieve the same level of thick, rubbery opacity and pure, punchy color as a solid layer of screen-printed plastisol ink.

Can This Method Create a Uniquely Tactile and Durable Finish?

When you run your hand over a screen-printed logo, what do you feel? You can feel the logo. It has a distinct, slightly raised, and often smooth texture. This tactile quality is a direct result of that thick layer of ink sitting on the fabric.

This isn't just a matter of feel; it's a matter of durability. Because the plastisol ink is essentially a liquid PVC that is heat-cured (at around 160°C / 320°F), it forms a permanent, flexible, and incredibly tough layer of plastic that is bonded to the fabric fibers. This finish is exceptionally resistant to cracking, peeling, and fading, even after many washes.

For an accessory like a heavily used baseball cap or a promotional tote bag, isn't this durability just as important as the initial boldness?

How Does the Curing Process Ensure Durability?

What happens when the ink is heated? The heat causes the plastisol ink particles to melt and fuse together, and at the same time, bond with the fibers of the fabric. Proper curing is a science. If the ink is under-cured, it will crack and wash off. If it's over-cured, it can become brittle. As a manufacturer, we have our curing tunnels precisely calibrated to ensure a perfect, permanent bond every time. This is a key part of our quality control process.

Why is This Better for High-Wear Items?

Why is this ideal for accessories? Accessories like caps, bags, and umbrellas often face more friction and abrasion than a standard t-shirt. Picture a baseball cap being tossed into a gym bag, its brim rubbing against rough fabric edges; a tote bag slung over a shoulder, its printed surface brushing against keys, coins, and the occasional sharp corner of a laptop; an umbrella handle gripped tightly in rain-soaked hands, its design enduring the scrape of wet pavement as it's tucked under an arm. The tough, flexible nature of a properly cured screen print can withstand this wear and tear far better than thinner ink applications that can be worn away more easily—those delicate layers, once smudged or scratched, fade into ghostly outlines, losing their vibrancy and clarity with every mishap.

Why is it Ideal for Simple, Graphic Logos?

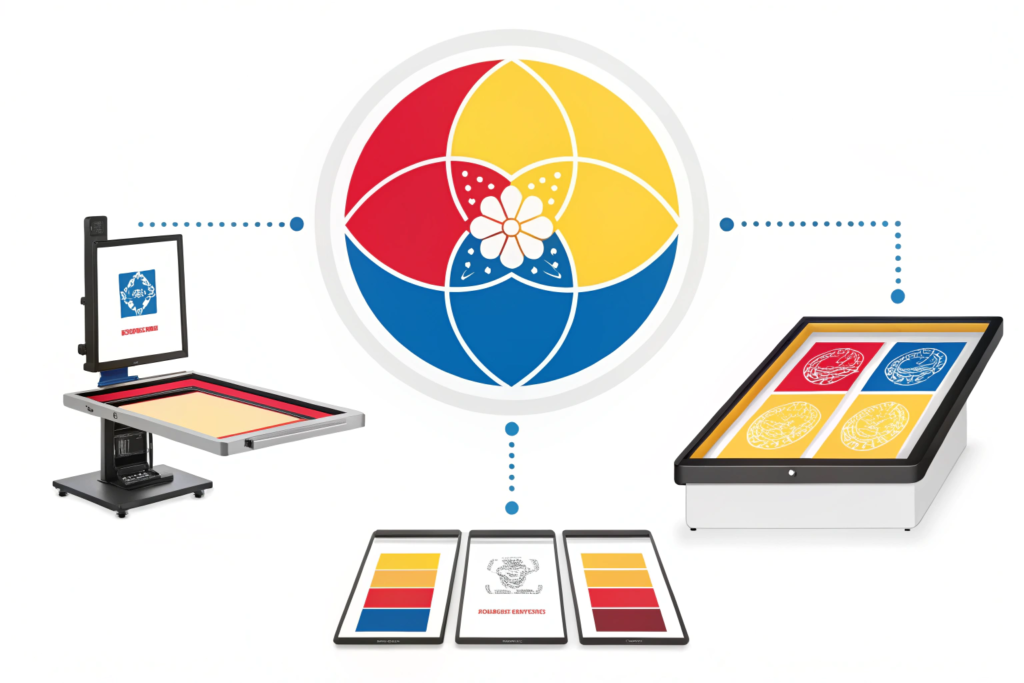

Is screen printing the best choice for every single design? No. Its greatest strength lies in printing spot colors. A spot color is a single, solid, pre-mixed color. A bold logo is often made up of just one, two, or three distinct spot colors.

The screen printing process is set up to handle this perfectly. Each color in your design requires its own separate screen. The artwork is separated into its color components, and a screen is created for each one. The product is then printed with one color at a time. This method is incredibly precise for reproducing the exact Pantone color of your brand.

Why is it Less Ideal for Photographs?

Can you print a photo with screen printing? While it's technically possible using a process called "four-color process" (CMYK), it's not where screen printing shines. It's difficult to reproduce the subtle gradients and millions of colors in a photograph. For photorealistic images, digital printing (DTG) is a far superior choice. But for a bold, vector-based logo, screen printing's spot color method is more vibrant and precise.

How Does This Affect the Cost?

How does the number of colors impact the price? Since each color requires its own screen and its own print run, the cost of screen printing is directly tied to the number of colors in your design. A one-color logo is the most cost-effective. A five-color logo will be significantly more expensive. This is why it's the perfect, budget-friendly choice for the simple, one or two-color logos that many brands use.

How Does it Offer Unmatched Cost-Effectiveness at Scale?

When you're producing hundreds or thousands of accessories, what is one of your biggest concerns? It's the unit cost. This is another area where screen printing is the clear winner for bulk orders.

The main costs in screen printing are in the setup: creating the screens and configuring the printing press. This setup cost is the same whether you are printing 50 pieces or 5,000 pieces. Therefore, as the quantity of your order increases, that initial setup cost is spread out over more units, causing the price per piece to drop dramatically.

For a brand looking to produce a large run of promotional items or a core collection piece, isn't this economy of scale a massive advantage?

Why is it Not Great for Very Small Orders?

What if you only want to print ten hats? Because of the high setup cost, screen printing is not economical for very small runs. For a one-off sample or a tiny order, the setup cost would make the price per hat astronomically high. In these cases, digital printing or heat transfer methods are a much better financial choice. But once your order quantity hits 50-100 pieces and above, screen printing quickly becomes the most cost-effective option.

How Does This Help You Plan Your Budget?

How does this knowledge help you? It allows you to plan your buying budget more effectively. You know that if you can increase your order quantity for a screen-printed item, your unit cost will go down, which can increase your profit margin or allow you to offer a more competitive retail price.

Conclusion

It delivers unmatched color vibrancy and opacity by laying down a thick layer of ink. It creates a uniquely tactile and durable finish that can withstand heavy use. It is perfectly suited for the spot-color nature of graphic logos, and it offers incredible economies of scale, making it the most cost-effective choice for bulk production.

When your brand's identity is tied to a bold, powerful logo, you need a printing method that does it justice. For a result that is as strong and confident as your design, screen printing is, and remains, the best choice.

We are experts in this technique and can advise you on how to prepare your artwork for the best possible screen-printed result. If you're ready to bring your bold logo to life, please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com.