You have a brilliant design for a new accessory or garment. The sketches are perfect, the vision is clear. But in the race from concept to consumer, time is the ultimate currency. How do you ensure your vision translates perfectly into a tangible product, resonates with your target market, and hits the shelves at the right moment? The answer lies in a critical, iterative process that bridges the gap between idea and reality: fast prototyping. In an industry defined by fleeting trends and fierce competition, why is speed in this phase not just an advantage, but an existential necessity for fashion brands?

Fast prototyping is essential for fashion brands because it de-risks product development, accelerates time-to-market, enhances creative precision, and enables data-driven decision-making before costly bulk production begins. It transforms the design process from a high-stakes gamble into a series of low-risk, rapid experiments. For a brand, this means the ability to validate ideas with real samples, gather actionable feedback, and make crucial adjustments in weeks—not months. As a manufacturer that partners with forward-thinking brands at Shanghai Fumao Clothing, we see fast prototyping as the engine of innovation, allowing designers to explore, fail, and perfect with agility, turning conceptual sparks into commercial successes.

This capability is the difference between leading a trend and chasing it. Let's explore the multifaceted reasons why speed in prototyping is a non-negotiable pillar of modern fashion business strategy.

How Does Fast Prototyping De-Risk the Entire Production Process?

The most significant financial risks in fashion occur during bulk production. Committing to thousands of units of a flawed design is a catastrophe. Fast prototyping acts as a systematic risk mitigation tool, identifying and solving problems when they are cheap and easy to fix.

Prototyping de-risks by enabling physical verification and problem-solving. A sketch or 3D render cannot reveal how a fabric actually drapes, how a clasp feels to open, or where a seam might pull under stress. A physical prototype does. Fast iteration allows you to:

- Test Material Compatibility: Verify if the chosen fabric works with the intended structure and hardware.

- Evaluate Construction and Fit: Identify construction flaws, uncomfortable seams, or poor ergonomics.

- Assess Aesthetic Details: See the true color, print scale, and proportion in real life, under real lighting.

- Validate Cost and Manufacturing Feasibility: Collaborate with the factory to identify overly complex or expensive design elements that can be simplified (value engineering) without sacrificing design intent.

By catching these issues early, you avoid the exorbitant costs of reworking or scrapping bulk inventory, protecting your margin and brand reputation. This aligns with lean manufacturing principles of building quality in at the source.

What is the True Cost of Skipping or Rushing Prototyping?

Skipping thorough prototyping to "save time" is a classic false economy. The costs manifest later as:

- Bulk Production Errors: A single undiscovered flaw replicated across 10,000 units.

- Massive Rework Expenses: Unpicking and re-sewing, or worse, writing off entire batches.

- Missed Launch Dates: Delays from last-minute crisis management.

- Customer Returns and Brand Damage: Shipping a product with functional or quality issues.

Fast prototyping is an investment that pays for itself many times over by preventing these downstream disasters.

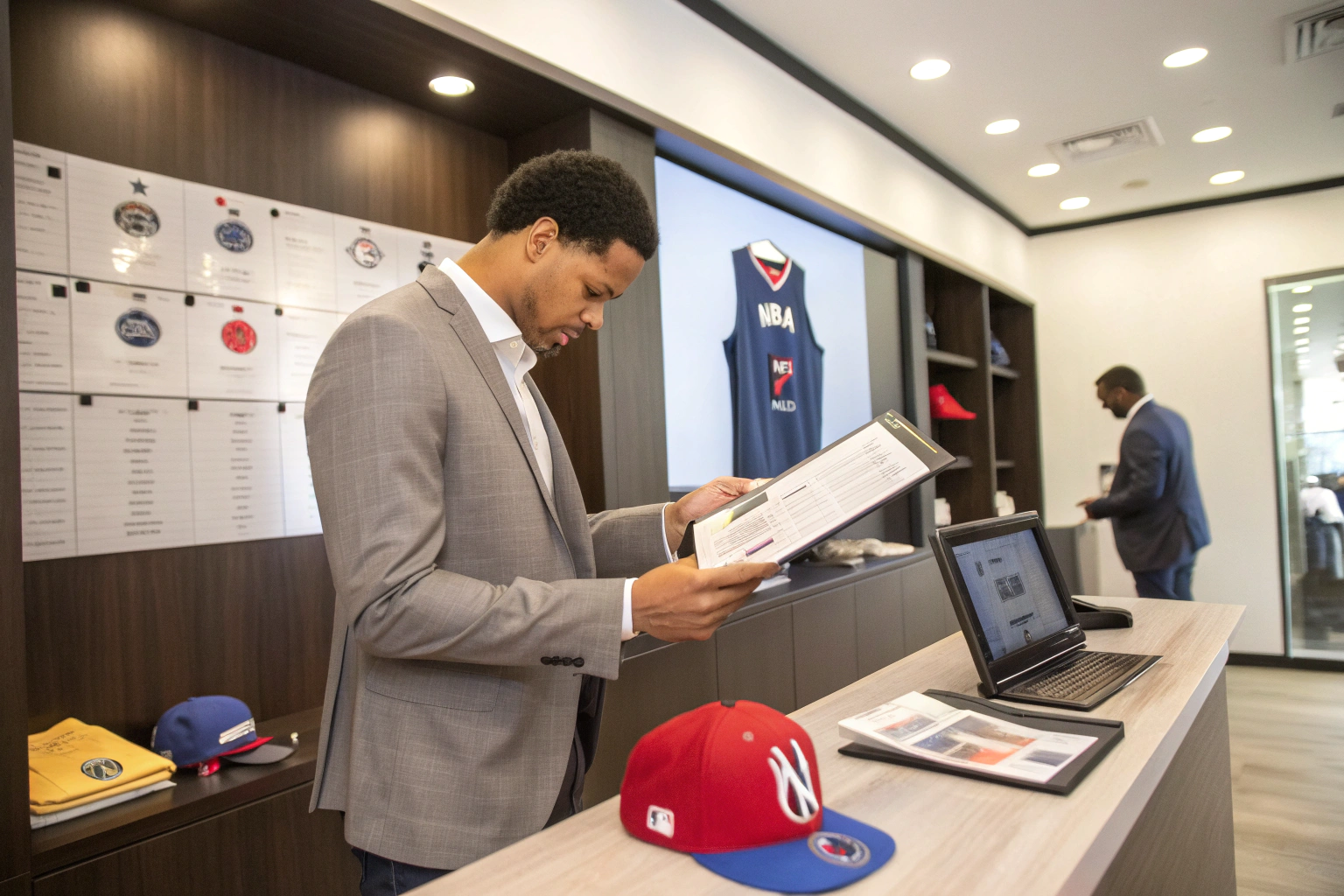

How Does it Improve Communication with Your Manufacturer?

A physical prototype is a universal language. It eliminates ambiguity between your vision and the factory's interpretation. Fast cycles mean you can give precise, visual feedback ("please move this dart 2cm to the left, like on this revised sample"), leading to perfect alignment before the production order is placed. This creates a collaborative partnership rather than a transactional relationship.

How Does it Drastically Accelerate Time-to-Market?

In fashion, being first (or early) is a monumental competitive advantage. Fast prototyping compresses the development timeline, allowing you to capitalize on trends while they are still fresh and respond to market signals with agility.

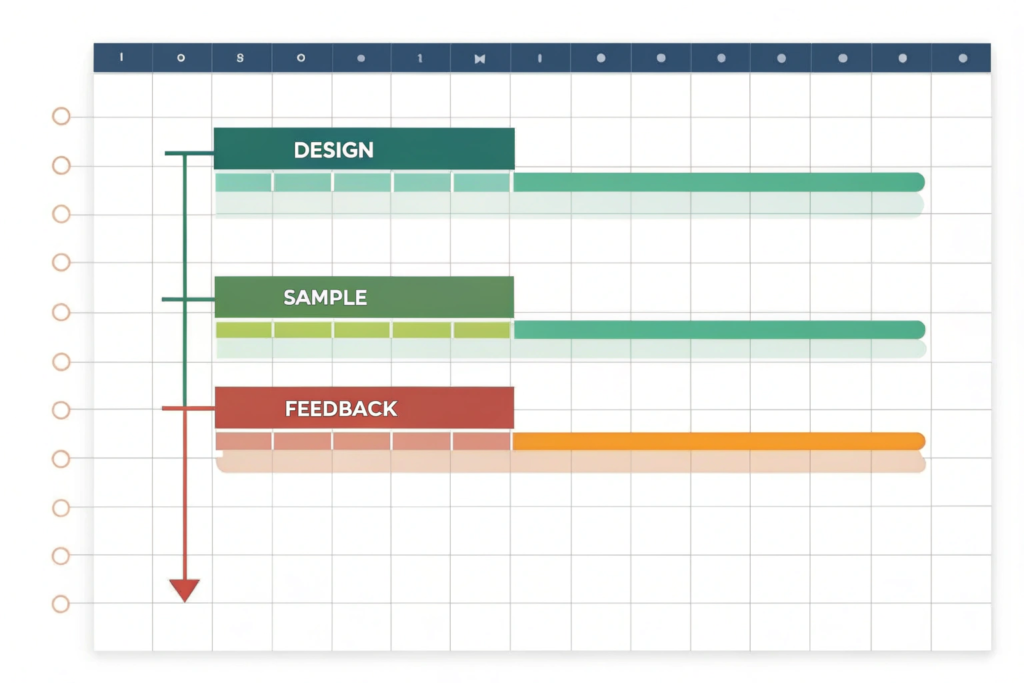

Speed-to-market is achieved by parallel processing and condensed feedback loops. Instead of a linear, slow sequence (design -> wait for sample -> review -> send back -> wait again), fast prototyping enables overlapping phases. While one sample is being made, you can be finalizing artwork for the next. Digital tools like 3D prototyping software can preview adjustments before a physical sample is even cut, saving iterations. When physical samples are produced quickly (thanks to manufacturers with dedicated sample rooms and efficient processes), you can review, decide, and approve in days. This agility allows you to:

- Launch More Collections Per Year: Supporting a "see now, buy now" or frequent drop model.

- Test and React to Trends: Quickly prototype a style inspired by an emerging trend seen at a fashion week or on social media.

- Shorten the Critical Path: Reduce the time from initial concept to having sellable stock in your warehouse.

This responsiveness is a core capability of successful fast-fashion and agile supply chains.

Can Fast Prototyping Enable a "Test and Respond" Business Model?

Absolutely. Brands can use fast prototyping to create small-batch, pre-production samples for market testing. This could involve:

- Selling a limited run on your website to gauge demand and collect customer reviews.

- Showing samples to key wholesale buyers at trade shows or meetings to secure pre-orders before committing to full production.

- Using samples for professional photography and marketing campaigns to build buzz while production is being finalized.

This data-driven approach removes guesswork from inventory planning.

How Does it Affect Seasonal Planning?

It provides buffer time. When prototyping is fast, you finish the development phase earlier in the seasonal calendar. This gives you more time for production, shipping, and marketing, reducing last-minute panic and allowing for strategic flexibility if a particular prototype exceeds expectations and you want to increase the order quantity.

How Does it Enhance Creative Exploration and Product Quality?

Speed in prototyping doesn't mean compromising on creativity; it liberates it. It allows designers to explore more ideas, refine details to a higher degree, and achieve a better final product because they are not constrained by time.

Creative enhancement happens through experimentation and refinement. With a fast turnaround, a designer can afford to try a version with a contrasting trim, then another with a different pocket configuration. This "what if" exploration leads to unexpected innovations and a more polished final design. It raises the quality ceiling because you can iterate on fit, finish, and feel multiple times, homing in on perfection. For technical accessories, this might mean prototyping with three different grades of metal for a buckle to find the optimal balance of weight, finish, and cost. AtShanghai Fumao Clothing, our in-house sample team facilitates this creative dialogue, helping brands refine their vision efficiently.

How Does it Empower Better Decision-Making on Materials and Details?

Seeing and touching a material on a real prototype is irreplaceable. A tech sheet might list a fabric as "soft," but only a prototype reveals if it's the right kind of soft. Fast iteration allows you to swap materials mid-process: "This felt is too stiff, let's try the wool blend for the next sample and compare." This tactile decision-making results in a product that feels coherent and high-quality.

What Role Does Digital Prototyping Play?

Digital tools (like CLO 3D, Browzwear) are becoming integral to the fast prototyping ecosystem. They allow for:

- Instant Visualizations: See a 3D model of the design in different colors and patterns.

- Fit and Drape Simulation: Especially useful for apparel, to assess fit on a digital avatar before cutting fabric.

- Reducing Physical Iterations: Use digital feedback to solve obvious problems, so the first physical sample is already at an advanced stage.

The most effective approach is a hybrid of digital speed and physical verification.

What Are the Strategic Business Advantages?

Beyond the operational benefits, fast prototyping confers key strategic advantages that strengthen a brand's market position and financial health.

Strategic advantages include:

- Reduced Inventory Risk and Waste: By validating products before bulk orders, you produce what you know will sell, aligning with a demand-driven model and reducing deadstock—a major financial and environmental concern.

- Enhanced Customization and Personalization Capability: Speed enables made-to-order or small-batch personalized offerings, catering to niche audiences and commanding a premium.

- Stronger Intellectual Property (IP) Protection: Getting a tangible product sample produced and documented quickly can help in securing design patents or establishing prior art.

- Competitive Moat: The ability to develop and launch products faster than competitors becomes a core competency that is difficult to replicate, especially when supported by a trusted manufacturing partner.

This strategic agility is what separates thriving brands from those struggling to keep up.

How Does it Impact Sustainability Goals?

Fast prototyping is a tool for sustainable design. It helps "get it right the first time," minimizing material waste from bulk production errors. It also supports the development of higher-quality, longer-lasting products because more time can be spent perfecting durability. Furthermore, it enables the testing of new sustainable materials in a low-risk way, accelerating their adoption.

How Does it Build a More Resilient Supply Chain?

A brand that prototypes quickly can adapt quickly. If a key material suddenly becomes unavailable or too expensive, fast prototyping allows for rapid redesign and testing of an alternative. This resilience is invaluable in a world of supply chain disruptions.

Conclusion

Fast prototyping is not a mere step in the fashion product development cycle; it is the dynamic core of a modern, responsive, and de-risked business model. It empowers brands to validate creativity with precision, accelerate commercial launches, mitigate catastrophic financial risks, and build products that truly resonate with the market. In an industry where timing and relevance are everything, the speed to iterate is ultimately the speed to succeed.

For fashion brands, investing in partnerships and internal processes that prioritize rapid prototyping is an investment in longevity, profitability, and creative freedom. It transforms the daunting journey from concept to customer into a controlled, confident, and iterative sprint.

If you are looking for a manufacturing partner that understands the critical importance of fast, high-fidelity prototyping to bring your fashion visions to life with speed and accuracy, we invite you to collaborate with us. At Shanghai Fumao Clothing, our dedicated sample development team is structured to support your iterative creative process. For a consultation on accelerating your product development, please contact our Business Director, Elaine. Let's build your next collection, iteratively and intelligently. Reach Elaine at: elaine@fumaoclothing.com.