Are you developing scarves, hats, or neck gaiters for the performance-driven European outdoor market but unsure which fabrics truly block the wind while maintaining style and comfort? Do technical terms like "CFM" and "membrane" feel disconnected from the fashion-forward aesthetic your brand needs? You're navigating the crucial intersection of technical performance and consumer appeal. European outdoor retailers and their customers demand verifiable functionality without sacrificing design, making fabric selection your most critical decision.

The answer lies in a tiered approach to windproofing, using specific fabric constructions, coatings, and laminates. True windproofness is achieved not just with dense weaves, but with engineered barriers that block air penetration while managing moisture (sweat) to prevent chilling. For fashion accessories, the challenge is to integrate these technologies into fabrics that are soft, drape well, and look attractive in a retail setting.

This guide will break down the key fabric technologies for windproof accessories. We'll explore high-density natural and synthetic weaves, modern technical membranes and coatings, and innovative blended solutions that balance performance with aesthetics. We'll also cover the testing standards European retailers require and how to communicate these features effectively to the end consumer.

How Do Fabric Construction and Density Create Wind Resistance?

The first line of defense against wind is the physical structure of the fabric itself. By tightly weaving or knitting fibers together, you reduce the spaces (pores) through which air can pass. This method provides inherent wind resistance without additional chemical treatments, often resulting in a more natural hand feel and better breathability.

Key constructions for inherent wind resistance:

- Tightly Woven Nylon or Polyester: Fabrics like ripstop nylon or high-density polyester taffeta with a high thread count (e.g., 70D or higher with a dense weave like plain or twill) offer excellent wind blockage. They are lightweight, durable, and have a subtle sheen common in technical apparel.

- Microfiber Fabrics: Made from ultra-fine synthetic filaments, these fabrics create an exceptionally dense surface with very small pores. Softshell fabrics often use a microfiber polyester face for wind resistance and a brushed interior for warmth.

- Wool Melton: A traditional, heavyweight wool fabric that is heavily milled (felted) to create an incredibly dense, smooth surface. It is naturally wind-resistant, warm, and has a premium, classic aesthetic perfect for winter hats and scarves. However, it can be heavy and less packable.

The effectiveness of a woven fabric is often measured by its CFM (Cubic Feet per Minute) rating—the volume of air that can pass through one square foot of fabric under a standard pressure. A truly windproof fabric typically has a CFM below 5. For context, a standard cotton shirt might be 60+ CFM.

What Are the Performance Limits of Densely Woven Fabrics?

While effective, dense weaves have trade-offs:

- Breathability vs. Windproofness: A very tight weave that blocks all wind may also trap perspiration (moisture vapor), leading to condensation and clamminess during activity. This is the core challenge of outdoor performance.

- Weight: Achieving high wind resistance through density alone can make the fabric heavier.

- Water Resistance: A tightly woven fabric can be treated with a DWR (Durable Water Repellent) finish to shed light rain, but it is not waterproof without a membrane. Wind can drive rain through the pores.

For active-use accessories like running neck gaiters or ski hats, a dense weave alone may not suffice. This is where more advanced technologies come into play.

Can Natural Fibers Like Wool Be Effectively Windproof?

Yes, but through a different mechanism. Wool, especially in dense, felted constructions like Melton or Boiled Wool, is excellent at breaking the wind. The fibers are scaly and interlock tightly when milled, creating a dense mat that air cannot easily penetrate. Its natural hydrophobic (water-repelling) properties and ability to wick moisture while retaining heat make it a superb, natural choice for cold-weather accessories. For European brands emphasizing natural and sustainable materials, high-quality wool is a compelling option that aligns with the demand for eco-friendly fabrics.

What is the Role of Membranes and Coatings in True Windproofing?

For guaranteed, high-performance windproofness—especially for activities like cycling, alpine hiking, or skiing—fabrics integrated with membranes or polymer coatings are the industry standard. These technologies provide a continuous, micro-porous or non-porous barrier that blocks wind (and often water) completely while allowing moisture vapor to escape.

Core Technologies:

- ePTFE Membranes: The most famous is GORE-TEX® (and similar generic expanded Polytetrafluoroethylene membranes). These membranes have billions of microscopic pores per square inch. The pores are smaller than a water droplet (keeping liquid out) but larger than a moisture vapor molecule (allowing sweat to evaporate out). This creates a completely windproof and waterproof, yet breathable barrier. It is usually laminated between a face fabric and a lining.

- Polyurethane (PU) Coatings & Laminates: A layer of PU is applied to the back of a fabric. A micro-porous PU coating functions similarly to ePTFE but is generally less breathable and more affordable. A windproof PU film laminate (a solid, non-porous film) provides absolute wind and water protection but with lower breathability. These are common in softshell and windbreaker fabrics.

For accessories, these technologies are often used in lightweight, packable neck gaiters, brimmed hats, and technical hoods.

How Do Laminated Membranes Differ from Coatings?

The construction method impacts performance, durability, and feel.

- 3-Layer Laminate: A membrane is permanently bonded between a durable outer fabric and a protective inner lining. This is robust, highly performance-oriented, and often used in hardshell jackets. For accessories, it might be used in high-end ski face masks or mountaineering balaclavas.

- 2.5-Layer Laminate: A lighter version where the membrane is bonded to an outer fabric and protected by a printed pattern or very light coating on the inside. This is ideal for ultra-packable, lightweight accessories.

- Coating: A PU layer is directly applied to the back of the fabric. It's more cost-effective and can be made breathable (micro-porous), but the coating can degrade with abrasion and washing over time.

When sourcing, a supplier like Shanghai Fumao Clothing can guide you on the best construction for your specific accessory type and price point.

What Are "Softshell" Fabrics and Their Role in Accessories?

Softshell is a category, not a single fabric. It typically refers to a multi-layer fabric designed to offer a combination of wind resistance, water repellency, breathability, and stretch in a single, soft, and quiet material. A common softshell construction for accessories is a bi-component knit: a tight, wind-resistant outer face (often polyester) bonded or laminated to a soft, insulating, and moisture-wicking inner layer (like polyester fleece or brushed microfiber). This creates a versatile, all-in-one fabric perfect for hats, gloves, and scarves that need to perform during high-output activities in cold, windy conditions.

How to Blend Performance with Aesthetics for Fashion Accessories?

The European outdoor market values technical performance but rejects a purely utilitarian look. The success of brands like Arc'teryx, Patagonia, and Goldwin lies in marrying cutting-edge fabrics with clean, modern design. Your fabric must perform and pass the visual and tactile test in a high-end retail environment.

Strategies for blending performance with style:

- Face Fabric Selection: Choose a technical outer fabric with a desirable hand feel and visual texture. For example, a matte-finish, textured polyester instead of a shiny, crinkly nylon. Use sophisticated, seasonally relevant color palettes.

- Lining Choices: Use performance linings that also feel luxurious. Brushed microfiber, moisture-wicking mesh, or even thin Polartec® fleece can provide comfort and function.

- Minimalist Branding: Integrate branding through embossed logos, tonal stitching, or discrete reflective elements rather than large, garish labels.

- Clean Finishing: Ensure all seams are well-constructed, edges are bound neatly, and any adjustable features (like drawcords) are sleek and functional.

The fabric should tell a story of considered design, similar to how acetate communicates luxury through its inherent qualities.

What Fabric Finishes Enhance Both Function and Feel?

Technical finishes are crucial for the end-user experience:

- DWR (Durable Water Repellent): A must-have finish for any wind-resistant outer fabric. It causes water to bead up and roll off, preventing the fabric from becoming saturated and cold. Modern PFC-free DWR finishes are now standard for environmentally conscious European brands.

- Anti-Odor Treatments: Treatments using silver ions or other technologies inhibit bacterial growth, a key feature for accessories worn close to the face during activity.

- Brushed or Fleece Backing: Adds warmth, a soft hand feel, and wicks moisture. This turns a simple windproof shell into a cozy, functional accessory.

These finishes should be specified in your tech pack and verified during the sampling and quality control process.

How to Source Fabrics That Meet Both Technical and Aesthetic Standards?

Work with mills and suppliers who specialize in technical fabrics for the European outdoor sector. Attend fabric sourcing fairs like Performance Days or Première Vision Sport & Tech. When evaluating a supplier:

- Request technical data sheets for any fabric, which should include CFM rating, waterproofness (mm), breathability (RET or MVTR), weight (GSM), and composition.

- Ask for swatches and physical samples to assess hand feel, drape, and color.

- Inquire about certifications like Bluesign® or OEKO-TEX Standard 100, which are highly valued in Europe and ensure responsible chemical management.

- Discuss minimum order quantities (MOQs) for custom color development to match your aesthetic vision.

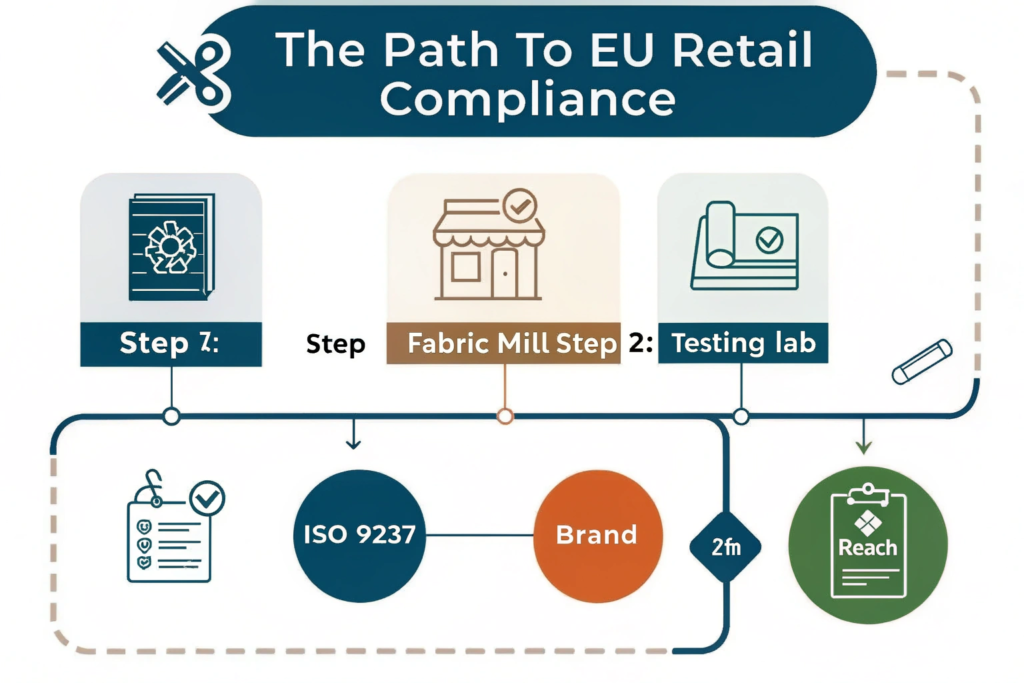

What Testing and Certification Do European Retailers Demand?

European retailers, especially large chains like Decathlon, Globetrotter, or AS Adventure, have strict sourcing protocols. They require objective proof of performance claims to protect their brand and comply with regulations like the EU's Product Environmental Footprint (PEF) and marketing directive.

Key Tests for Windproof Accessories:

- Air Permeability Test (ISO 9237 / EN ISO 9237): Measures CFM. The gold standard for proving windproofness. A result of <5 CFM is typically marketed as "windproof."

- Water Resistance Test (ISO 811 / EN 20811): Measures the hydrostatic head in mm. While not always required for windproof items, a rating of 1,500mm+ is good for weather resistance.

- Breathability/Moisture Vapor Transmission Test (ISO 15496 / RET rating): Proves the fabric allows sweat vapor to escape.

- Durability Tests: Abrasion resistance (Martindale), colorfastness to washing and light.

You will need to provide third-party test reports from accredited laboratories (like SGS, Hohenstein, or TESTEX). Many retailers also require a Supplier Declaration of Conformity and evidence of REACH compliance (restricted chemicals).

How to Prepare a Technical File for Retailer Submission?

Your submission package should be as professional as your product:

- Product Technical Data Sheet: A one-page summary of the product with fabric specifications, claimed performance (CFM <5, DWR), and construction details.

- Laboratory Test Reports: Original copies of the relevant ISO standard tests conducted on the final fabric/accessory.

- Material Certificates: Bluesign, OEKO-TEX, or GRS certificates for the fabrics and components.

- Risk Assessment: Documentation showing due diligence on restricted substances (REACH SVHCs).

- Physical Sample.

Having this dossier ready accelerates the onboarding process and demonstrates your technical competence, a key part of building trust as a supplier.

Can You Use Generic Membranes or Must You License Branded Tech?

This is a strategic choice. Branded technologies like GORE-TEX® or Polartec® Windbloc® carry immense consumer trust and marketing power but come with licensing fees, strict quality control audits, and co-branding requirements. They are ideal for positioning at the premium end of the market.

Generic or proprietary membranes (often from Taiwanese or Chinese mills like Hyvent, Entrant, or Dermizax) offer similar technical performance at a lower cost and with more design freedom. The trade-off is the lack of brand recognition. For many fashion-forward outdoor accessories, high-performing generic membranes paired with strong own-brand storytelling are a successful and profitable path. The decision hinges on your brand's price point and marketing strategy.

Conclusion

Selecting windproof fabrics for European outdoor accessories requires a nuanced understanding of performance benchmarks, material technologies, and market expectations. By choosing between high-density weaves, advanced membranes, and versatile softshells, and by rigorously testing to ISO standards, you can create products that meet the stringent demands of both retailers and end-users.

The winning formula combines verified technical performance (CFM <5) with considered aesthetics, sustainable finishes, and comprehensive compliance documentation. This approach ensures your scarves, hats, and gaiters are not only functional in the Alpine wind but also desirable on the retail shelf.

Ready to develop technically certified, fashion-forward outdoor accessories? At Shanghai Fumao Clothing, we specialize in sourcing performance fabrics, navigating compliance testing, and manufacturing accessories that meet the high standards of the European market. Contact our Business Director Elaine at elaine@fumaoclothing.com to engineer your next collection.