As a professional buyer like Ron, you're constantly on the hunt for that perfect product: the one that's on-trend, has huge volume potential, and, most importantly, can be sourced at a price that guarantees a healthy profit margin. Hair clips are a fantastic category for this—they are a high-volume, impulse-buy item. But the word "affordable" can be a dangerous trap. Sourcing the cheapest hair clip is easy; sourcing a well-made, safe, and affordable hair clip that won't damage your brand's reputation is a much more complex challenge. So, where do you find a source that can deliver on price without sacrificing the quality and safety your customers expect?

To find affordable bulk hair clips, you must look beyond the sticker price and focus on the "Total Value." This means partnering directly with a specialist manufacturer who can offer cost-effective, high-volume production methods (like using automated molding and assembly), provide access to a library of existing toolings to save you money, and ensure full compliance with safety standards to protect you from costly recalls. True affordability is not about the lowest initial price; it's about the lowest total cost of ownership.

From my perspective as a manufacturer, the "price" conversation is one I have every day. And I can tell you that the most successful buyers don't just ask for the cheapest option. They ask for the smartest option. At Shanghai Fumao Clothing, we've built our business on being that smart partner. We help our clients engineer products to meet their target cost without compromising on the essential quality that protects their brand. Let me show you how to find a partner who can do the same for you.

Why Is Direct-from-Factory Sourcing the Key to Affordability?

The first and most significant step to achieving an affordable price is to remove the unnecessary middlemen from your supply chain.

Sourcing directly from a specialist factory is the key to affordability because it eliminates the 15-30% margin that a trading company or wholesaler would add on top of the factory price. By going direct, you are getting the product at its true cost of production, giving you the maximum possible room for your own profit margin.

This is the fundamental rule of sourcing. A trading company provides a service—they find a factory for you—but you pay for that service in the form of a higher unit price. When you build a relationship directly with a manufacturer like us, you get several advantages:

- Lower Price: You are not paying a middleman's markup.

- Better Communication: You are talking directly to the people making your product, which reduces errors and misunderstandings.

- Greater Transparency: You have a clear view into the production process and the factory's compliance and quality standards.

This direct partnership is the foundation of a cost-effective sourcing strategy and is the first step before you can explore specific cost-saving production methods.

How can you tell a factory from a trading company?

- Ask for a Factory Audit Report: A real factory will have a social audit report (like BSCI or Sedex). A trading company will not.

- Check Their Business License: A factory's license will list "manufacturing" or "production" in its scope of business. A trader's will list "wholesale" or "export."

- Request a Video Call Factory Tour: A real factory will be proud to walk you through their production floor on a video call. A trader will make excuses.

Is it harder to work directly with a factory?

A Purchase Order (PO) is much more than just a price quote or a simple request to buy. In the world of fashion accessory sourcing, it is the foundational legal document that turns a conversation into a clear, binding contract.

How Do Production Methods and Material Choices Impact the Price?

Once you're talking to a factory, the next step is to understand how the product is actually made. Small changes in materials or production methods can have a huge impact on the final cost.

The production method is a primary driver of cost. For plastic clips, using high-efficiency injection molding is far more affordable at scale than hand-cutting or CNC milling. For materials, choosing a standard, high-volume material like acrylic or ABS plastic is significantly more cost-effective than a niche or specialty material.

This is where a good manufacturing partner becomes a cost-saving consultant. We can look at your design and suggest smart adjustments:

- Material Choice: "You've requested a cellulose acetate clip, which is a premium, expensive material. We can achieve a very similar look using patterned acrylic, which would reduce the unit cost by 40%."

- Production Method: "Your design has a very complex shape. If we simplify this curve slightly, we can use a standard injection mold, which is much faster and cheaper per unit than needing to use a 5-axis CNC machine."

This process of "value engineering" is about making intelligent choices to reduce cost without sacrificing the core look and feel of the product. This is a crucial conversation to have before you start discussing tooling costs.

What are the most affordable materials for bulk hair clips?

- ABS Plastic: A very common, strong, and low-cost plastic. Great for solid-color clips.

- Acrylic (PMMA): Excellent for creating clips with patterns, transparent colors, or a tortoiseshell look. Very cost-effective in bulk.

- Basic Metal Alloys: For simple metal snap clips or barrettes, a standard iron or steel alloy is the most affordable option.

What makes a material expensive?

Low-volume, specialty materials (like biodegradable plastics derived from renewable resources such as corn starch or sugarcane, which require complex manufacturing processes to ensure proper degradation rates and mechanical strength, or cellulose acetate, a material often sourced from wood pulp or cotton linters that undergoes multiple chemical treatments to achieve desired properties) are more expensive.

Also, materials that are difficult or slow to process—such as those with high melting points requiring specialized heating equipment, or those that demand precise molding techniques to avoid defects like warping or uneven thickness—will increase the labor cost and therefore the unit price. These materials may necessitate longer production times, skilled technicians to handle their unique handling requirements, and additional quality control steps to ensure consistency, all of which contribute to higher overall costs per unit.

How Can You Leverage Existing Molds to Save Money?

For any custom-shaped plastic hair clip, a metal mold must be created. This mold can be a significant upfront investment. But there's a smart way to avoid this cost.

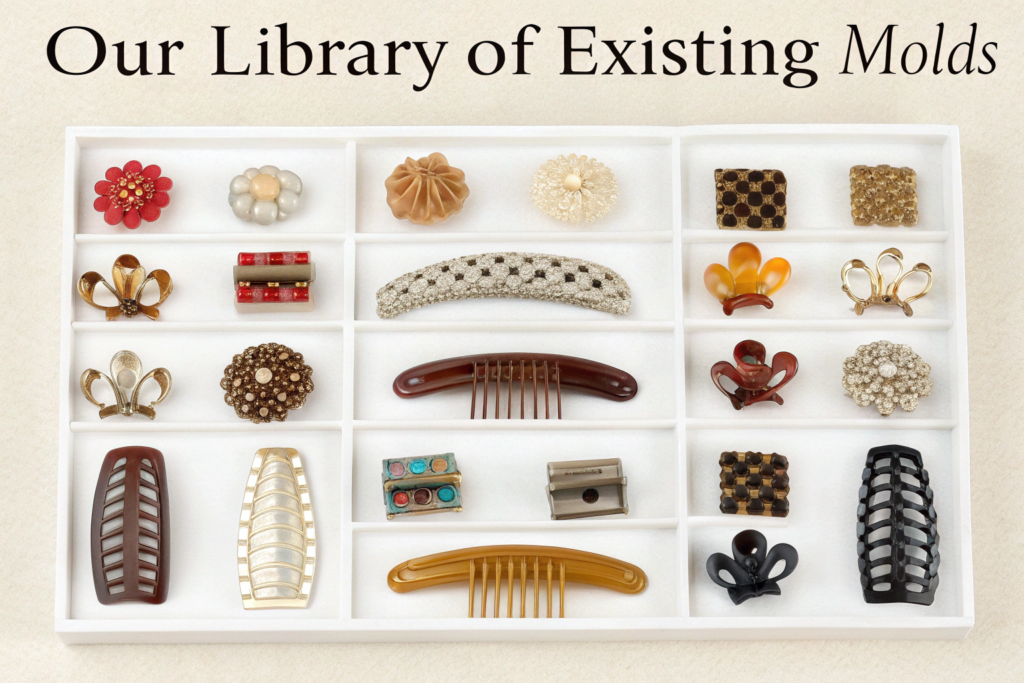

You can dramatically reduce your costs by choosing a hair clip shape for which the factory already has an existing mold, or "tooling." A factory that specializes in hair clips will have a library of hundreds of existing molds for classic shapes—claw clips, barrettes, etc. Using one of these means you don't have to pay the mold development fee.

This is one of the best "insider tricks" for affordable sourcing. A new mold can cost anywhere from $500 to $5,000. By using an existing mold, that cost becomes zero. You can still create a completely unique product by:

- Choosing a custom color: We can inject any Pantone color into an existing mold.

- Applying a custom print: We can take a classic clip shape from an existing mold and apply your unique pattern to it.

- Using a unique finish: We can give a classic shape a soft-touch matte finish or a high-gloss finish.

At Shanghai Fumao Clothing, we have a huge catalog of existing clip shapes that our clients can choose from. This allows them to launch a new collection with zero tooling investment, which is a huge advantage when you're trying to keep costs down and is a key part of ensuring a safe and compliant product.

Is the mold fee a one-time cost?

Yes. If you do decide to create a custom shape, you pay the mold fee once. The mold then belongs to you, and we will use it exclusively for your orders. This one-time fee covers the design, engineering, and production of a precision-crafted mold tailored specifically to your unique specifications, ensuring that every piece produced from it meets your exacting standards. Once the mold is created and approved by you, it becomes your property, stored securely in our facility under controlled conditions to maintain its integrity and longevity. For all subsequent orders, we will utilize this dedicated mold without any additional charges for its use, guaranteeing consistency, accuracy, and the highest quality in each custom item we produce for you.

What is the "MOQ"?

MOQ stands for Minimum Order Quantity. This is the smallest quantity a factory can produce for a specific item, typically determined by factors such as production setup costs, material handling, and equipment calibration. For items using an existing mold, which have already been designed, tested, and set up in the factory, the MOQ is often lower than for a brand-new custom item, where new molds must be created, requiring additional time, resources, and upfront investment.

Why Is Safety Compliance the Ultimate Cost-Saver?

It might seem strange to talk about safety testing in a conversation about affordability, but a product that fails safety standards can become the most expensive mistake you ever make.

Ensuring your products are fully compliant with safety regulations (like CPSIA in the US and REACH in the EU) is the ultimate cost-saver because it protects you from the catastrophic expense of a forced recall, potential lawsuits, and irreversible damage to your brand's reputation. The cost of proper testing is a tiny fraction of the cost of a single safety failure.

Imagine you import 50,000 hair clips that are later found to contain excessive levels of lead or phthalates. You would be legally required to recall all of them, issue refunds, and you could face significant fines. This is why working with a factory that understands and prioritizes compliance is not a luxury; it's a fundamental part of an affordable sourcing strategy. A cheap price from a factory that cuts corners on safety is not a good deal; it's a huge liability. We ensure all our materials are sourced from reputable suppliers and can provide full testing reports to prove our products are safe and compliant.

What are the key regulations to know?

- CPSIA (Consumer Product Safety Improvement Act): The main US law regulating children's products. It strictly limits lead and phthalate content.

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): A sweeping EU regulation that restricts thousands of potentially harmful chemicals.

Isn't testing expensive?

A single test can cost a few hundred dollars, with fees varying based on the complexity of the materials and the rigor of the testing protocols—ranging from basic chemical composition analysis to advanced stress-testing under extreme conditions.

However, a good factory will test their core materials regularly, scheduling routine checks at every production batch or even more frequently for critical components, ensuring that each incoming raw material meets stringent quality standards.

Conclusion

Finding affordable bulk hair clips is a strategic process, not a race to the bottom on price. True affordability comes from a smart, holistic approach. It starts with sourcing directly from a specialist factory to eliminate middlemen. It continues with a collaborative value engineering process to choose cost-effective materials and production methods. It's accelerated by leveraging the factory's library of existing molds to avoid tooling fees. And, most importantly, it is protected by an unwavering commitment to safety and compliance to avoid catastrophic hidden costs. By focusing on this "Total Value" approach, you can build a highly profitable, high-volume hair clip program without ever having to compromise on the quality and safety your customers deserve.

At Shanghai Fumao Clothing, this is how we define "affordable." We are experts at partnering with our clients to create products that are not just inexpensive, but are intelligently and responsibly engineered for commercial success.

If you are looking for a partner to help you build a smart and affordable accessory collection, let's talk. Please contact our Business Director, Elaine, at her email: elaine@fumaoclothing.com, to get started.