Mixing leather with fabric, metal with resin, straw with plastic—this is the creative chaos behind many of today's trendiest fashion accessories. But as global buyers, especially those from North America and Europe, dive deeper into the allure of mixed-media designs, sourcing these hybrid items becomes more complex than ever.

Sourcing accessories made of multiple materials presents unique production, compliance, and quality risks. Brands that want a smooth supply chain must anticipate these challenges and work with manufacturers who understand the nuances.

If you're sourcing accessories like sequined belts, faux fur-trimmed scarves, or headbands with a blend of metal and acrylic, this article outlines the main risks and offers smart tips to stay ahead of delays, defects, or customs issues.

Why Is Mixed-Media Accessory Sourcing More Complicated?

Handling fashion accessories with just one material is straightforward. But when two or more materials are combined—like leather and sequins in belts or plastic and velvet in headbands—it opens a world of complication.

Each material in mixed-media accessories comes with its own sourcing requirements, cost implications, and manufacturing techniques, which complicates both production and quality control.

What Are the Key Differences in Handling Each Material?

Leather, fabric, straw, acrylic, and plastic—each comes from different supply chains. For example, sourcing vegan leather for Western clients often requires REACH compliance, while glitter-coated plastics may need flammability testing for the U.S. market via CPSC-certified labs.

The finish quality of a headband made with woven straw and elastic is totally different from one using nylon and ABS plastic. Moisture resistance, dye-bleeding risks, and even storage conditions vary, causing delays if mishandled.

Are Production Lines Ready for Material Diversity?

Not always. Most small accessory workshops in Asia specialize in one type of material. That means when mixed-media orders come in, subcontracting often happens—leather handled by one unit, plastic molding by another. This segmentation results in coordination issues, production inconsistencies, or shipment delays.

A supplier like ours at AceAccessory, with integrated lines for fabric, straw, leather, and plastic, avoids such chaos. We oversee development from sourcing to finishing, reducing lead time and improving control.

What Compliance and Safety Challenges Arise?

Accessories with mixed media are more vulnerable to non-compliance. U.S. and EU regulations differ on chemical content, flammability, labeling, and origin declarations.

Testing becomes more rigorous as each material component might fall under different safety standards, increasing cost and complexity.

Which Certifications Are Commonly Required?

Most U.S. retailers will ask for Prop 65 declarations for plastic or rubber content and flammability reports for anything textile-based. European buyers usually demand REACH or OEKO-TEX certificates, especially for baby accessories or headbands that touch the skin.

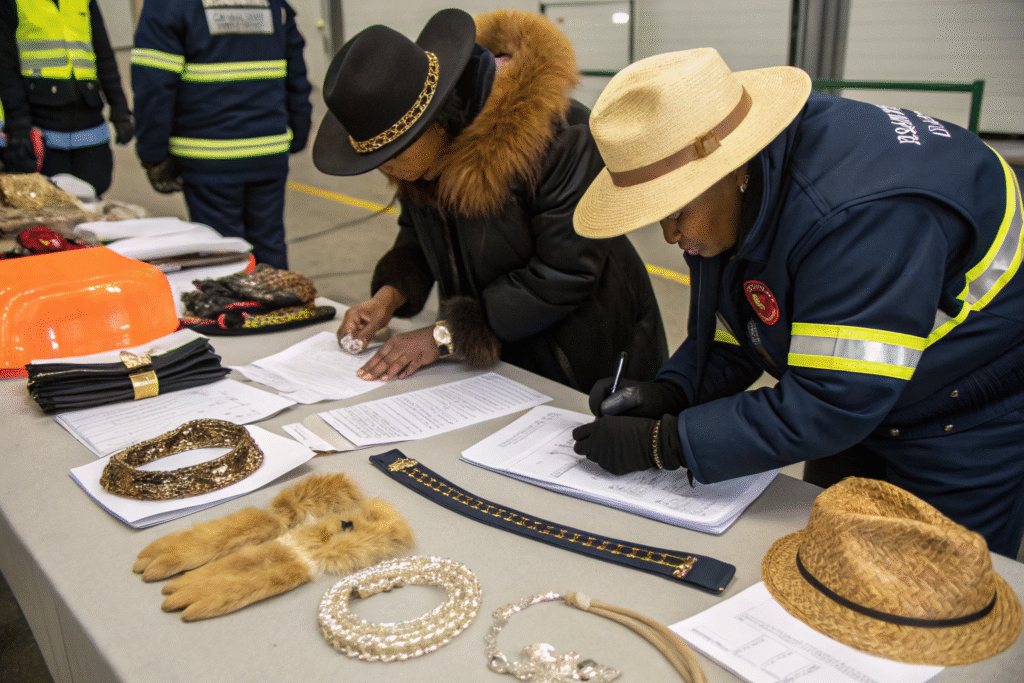

A fur-lined glove with a PVC logo needs at least two separate tests. If the base material passes but the trim doesn’t, the product can't ship.

How Can Sourcing Agents and Factories Reduce Risk?

Experienced factories consolidate testing early during development. At AceAccessory, we pre-screen material batches and certify composite items before mass production. This avoids post-production recalls and reduces rejection rates at customs.

We also maintain digital certification archives for each client to simplify audits and reorders.

Do Mixed Media Designs Increase Production Lead Time?

Time is money—especially for brands with seasonal drops. When one accessory contains multiple materials, production can slow significantly due to coordination gaps.

Each additional material means extra development, testing, assembly, and in some cases, manual labor—adding up to longer lead times.

What Are Common Bottlenecks in Mixed-Media Accessory Orders?

Here’s a simple example: A fashion buyer requests a spring belt made of woven raffia, PU leather tips, and metallic loops. Now consider:

| Component | Lead Time | Origin |

|---|---|---|

| Raffia | 7–10 days | Local weaver |

| PU Leather | 5–7 days | Tannery |

| Metal Buckle | 5–10 days | Die casting unit |

Add time for sample approval, color correction, and final assembly, and suddenly a 20-day order becomes 35+ days.

How Do Professional Factories Handle This Timeline?

At AceAccessory, our in-house development team maps all material ETA schedules, while project managers conduct multi-point checkpoints throughout assembly. This is especially crucial during peak seasons like Back-to-School or Christmas when every day matters.

We also use buffer planning and maintain pre-approved material libraries for recurring clients to skip sampling delays.

How Does Packaging and Shipping Differ for Mixed Accessories?

Even packaging changes when multiple materials come together. Soft velvet headbands with metal embellishments can scratch. Straw items deform in heat. Belts with PVC trim crack under pressure.

Exporters must customize packaging not only for protection, but also for tariff codes, labeling, and retailer-specific display needs.

What Are the Shipping Risks for Multi-Material Accessories?

Combining metal, textile, and plastic can create unusual shipping declarations. Customs officers may flag items as “multi-classified,” requiring dual HS codes or further inspection.

Retailers like Target or Walmart often demand pre-packed shelf-ready packaging, meaning accessories must arrive pre-tagged and unit-boxed. Errors in labeling composite material ratios (e.g., “85% polyester, 15% PU”) can lead to import holds.

How Should Packaging Be Designed to Avoid Damage?

We solve this with a 3-layer system: surface protection (bubble or coated pouch), structural support (cardboard insert or molded tray), and outer packaging (master carton with humidity indicator). This prevents flattened straw hats or snapped embellishments during transit.

We also partner with logistics experts like Flexport to offer smart routing with shock-reducing pallets for delicate goods.

Conclusion

Sourcing mixed-media accessories isn't just about bold design—it's about anticipating complexity at every step. From diverse sourcing pipelines to layered compliance and careful packing, each phase demands a specialized factory partner.

At AceAccessory, we’re fully equipped in our Zhejiang facility to manage these hybrid product challenges. From pre-development material review, to testing, to dual-line production and export packaging—we deliver fast, accurate, and tariff-smart solutions.

If you’re sourcing accessories with multi-material designs, reach out to us. You can contact our Business Director Elaine at elaine@fumaoclothing.com for consultation and custom quotes tailored to your brand’s unique needs.